Degradable scaffold medical film preparation method

A kind of equipment, polylactic acid technology, applied in medical science, textiles and papermaking, non-woven fabrics, etc., can solve problems such as spinning difficulties, poor degradation controllability, slow degradation rate, etc., to achieve tissue regeneration, absorption, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

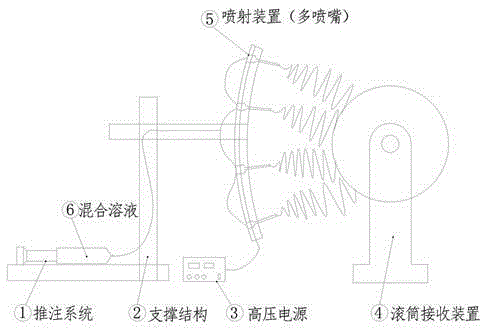

Image

Examples

Embodiment 1

[0022] (1) Preparation of polymer electrospinning solution: Dissolve polylactic acid (PLLA) material in ethyl acetate, put the prepared mixture on a magnetic stirrer for stirring (stirring time is 6 hours), stir and disperse evenly. The proportioning concentration of the electrospinning solution is 8%;

[0023] (2) Electrospinning process: put the solution obtained in step (1) in the feeding injector of the spinning equipment, the injection volume is 10ml / h, the high voltage power supply is 20kv, the injector and the rotating drum receiving device The receiving is 18cm; Finally, the mesh support medical film is obtained on the receiving drum;

[0024] (3) Removal of organic solvents: put the medical film prepared in step (2) in a vacuum drying oven, adjust the temperature to 50°, and the drying cycle to 6 hours. Until the residual organic solvent is less than the national standard.

Embodiment 2

[0026] (1) Preparation of polymer electrospinning solution: Dissolve polylactic acid (PLLA) material in the co-solution of ethyl acetate and DMF (1:1), and put the prepared mixture on a magnetic stirrer for stirring (stirring time is 6 hours), stir to disperse evenly. The proportioning concentration of the electrospinning solution is 10%;

[0027] (2) Electrospinning process: place the solution obtained in step (1) in the feeding injector of the spinning equipment, the injection volume is 9ml / h, the high voltage power supply is 20kv, the injector and the rotating drum receiving device The receiving is 20cm; Finally, the mesh support medical film is obtained on the receiving drum;

[0028] (3) Removal of organic solvents: put the medical film prepared in step (2) in a vacuum drying oven, adjust the temperature to 55°, and the drying cycle to 8 hours. Until the residual organic solvent is less than the national standard.

Embodiment 3

[0030] (1) Preparation of polymer electrospinning solution: Dissolve polylactic acid (PLLA) material in ethyl acetate and tetrahydrofuran (1:1), and stir the prepared mixture on a magnetic stirrer (stirring time is 5 hours ), and stir to disperse evenly. The proportioning concentration of the electrospinning solution is 12%;

[0031] (2) Electrospinning process: put the solution obtained in step (1) in the feeding injector of the spinning equipment, the injection volume is 11ml / h, the high voltage power supply is 20kv, the injector and the rotating drum receiving device The receiving is 20cm; Finally, the mesh support medical film is obtained on the receiving drum;

[0032] (3) Removal of organic solvents: put the medical film prepared in step (2) in a vacuum drying oven, adjust the temperature to 45°, and the drying cycle to 6 hours. Until the residual organic solvent is less than the national standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com