Production method for starch sugar

A production method and technology of starch sugar, which is applied in the field of starch sugar processing, can solve the problems of failure to fully utilize raw materials, sugar residues cannot be reused, and low starch conversion rate, so as to reduce incomplete liquefaction substances and save high-pressure steam Dosage, the effect of increasing the dry matter yield of starch sugar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

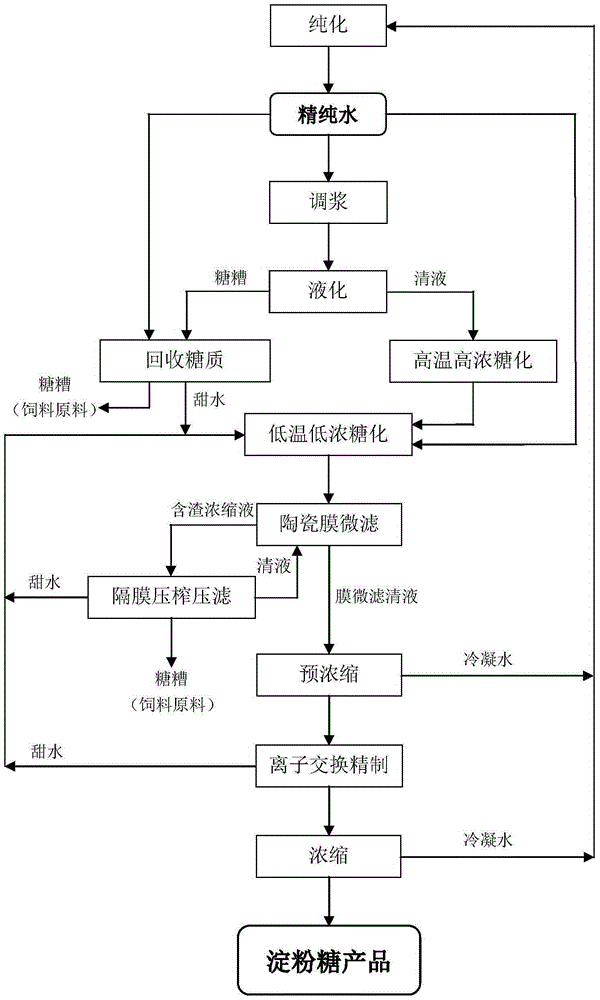

[0061] The production process flow chart of the present embodiment is as figure 1 As shown, the specific operation steps are as follows:

[0062] (1) Preparation of pure water: Recover the steam condensed water produced in the pre-concentration and concentration process of starch sugar, pass through a 350-mesh filter and then pass through the cation resin AMBERJET1000Na, the anion resin AMBERLITEIRA96CRF and the macroporous adsorption resin SD at a speed of 6BV / h -2 Ion-exchange resin compound bed, the prepared pure water with a conductivity of 2.5μS / cm, a 2-AP content of 0.16μg / L, and a pH of 5.05;

[0063] (2) Slurry preparation: preheat purified water to 60°C and mix with 100 parts by mass of edible cornstarch to make starch milk at 23~24°Bé, adjust the pH to 5.9~6.0 with 5%wt sodium carbonate solution, Add LiquozymeSupra high-temperature-resistant α-amylase equivalent to 0.03% of the edible starch mass, add food additive calcium chloride 5mg / kg starch milk, use waste heat...

Embodiment 2

[0071] (1) Preparation of pure water: Recover the steam condensed water produced in the pre-concentration and concentration process of starch sugar, pass through a 350-mesh filter and then pass through the cation resin AMBERJET1000Na, the anion resin AMBERLITEIRA96CRF and the macroporous adsorption resin SD at a speed of 6BV / h - Ion exchange resin compound bed composed of 2 to produce pure water with a conductivity of 2.8 μS / cm, a 2-AP content of <0.1 μg / L, and a pH of 6.45;

[0072] (2) Pure water mixing: After preheating the pure water to 63°C, mix it with 100 parts by mass of edible cornstarch to make starch milk at 20~21°Bé, adjust the pH to 5.5~ with 5%wt sodium carbonate solution 5.6, add LiquozymeSupra high temperature-resistant α-amylase equivalent to 0.01% of the edible starch mass, add food additive calcium chloride 50mg / kg starch milk, and maintain the temperature of starch milk at 60~61°C;

[0073] (3) Liquefaction: Starch milk is sprayed continuously at 105°C, fla...

Embodiment 3

[0079](1) Preparation of pure water: Recover the steam condensed water produced in the pre-concentration and concentration process of starch sugar, pass through a 350-mesh filter and then pass through the cation resin AMBERJET1000Na, the anion resin AMBERLITEIRA96CRF and the macroporous adsorption resin SD at a speed of 6BV / h - Ion exchange resin compound bed composed of 2 to produce pure water with a conductivity of 2.3μS / cm, a 2-AP content of <0.1μg / L, and a pH of 6.03;

[0080] (2) Slurry preparation: After preheating the purified water to 65°C, mix it with 100 parts by mass of edible cornstarch to make starch milk of 21~22°Bé, adjust the pH to 5.7~5.8 with 5%wt sodium carbonate solution, add LiquozymeSupra high temperature-resistant α-amylase equivalent to 0.02% of edible starch mass, add food additive calcium chloride 30mg / kg starch milk, and maintain the temperature of starch milk at 61~62°C;

[0081] (3) Liquefaction: Starch milk is sprayed continuously at 108°C, flashe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com