Method and device for performing recovery and resource utilization on heavy metal in waste acid

A heavy metal and recycling technology, applied to the improvement of process efficiency, photographic technology, instruments, etc., can solve the problems of high recycling cost, cumbersome process, secondary pollution, etc., to reduce the output of waste residue, avoid secondary pollution, and improve the recovery rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

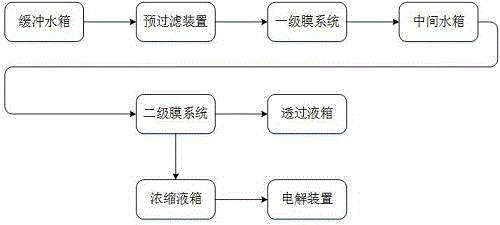

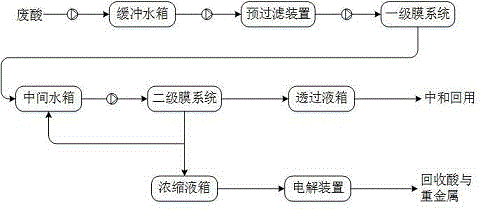

Method used

Image

Examples

Embodiment 1

[0075] Example 1 is a copper smelting waste acid, wherein the acid mass fraction (in sulfuric acid) is 7.2%, the fluoride ion concentration is 153mg / L, the chloride ion concentration is 1080mg / L, the copper ion concentration is 510mg / L, and the lead ion concentration The suspended solids and colloids in the waste acid are removed through the pre-filtration device and the first-stage membrane system. The mass fraction of acid in the permeate of the second-stage membrane system is 0.8%, the concentration of chloride ion is 1030mg / L, and the concentration of fluoride is 1030mg / L. The ion concentration is 140mg / L, the mass fraction of acid in the concentrate is 13.8%, the concentration of copper ions is 503mg / L, and the concentration of lead ions is 58.87mg / L. After the concentrate is electrolyzed by the electrolysis device, the mass fraction of acid in the electrolyte is about 14% %, the recovery rate of copper is 97.9%, and the recovery rate of lead is 95%.

Embodiment 2

[0076] Embodiment 2 is the waste acid of certain electroplating factory, and wherein acid mass fraction (in sulfuric acid) is 6.2%, and zinc ion concentration is 33.2mg / L, and copper ion concentration is 118mg / L, and lead ion concentration is 12.5mg / L, The nickel ion concentration is 20mg / L. The suspended solids and colloids in the waste acid are removed through the pre-filtration device and the primary membrane system. The mass fraction of acid in the permeate of the secondary membrane system is 0.68%, and the mass fraction of acid in the concentrate The concentration of zinc ions is 11.9%, the concentration of zinc ions is 32.8mg / L, the concentration of copper ions is 116.3mg / L, the concentration of lead ions is 11.6mg / L, and the concentration of nickel ions is 19.3mg / L. The acid mass fraction is about 12%, the recovery rate of zinc is 96.6%, the recovery rate of copper is 975%, the recovery rate of lead is 96%, and the recovery rate of nickel is 98.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com