Method for adjusting dissolved gases in boiler feed water

A boiler feed water and solubility technology, which is applied in separation methods, feed water heaters, chemical instruments and methods, etc., can solve the problems of accelerated flow corrosion, steam loss, large energy consumption, and high cost of oxygen scavenger in the feed water system. The effect of low comprehensive cost, simple structure and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

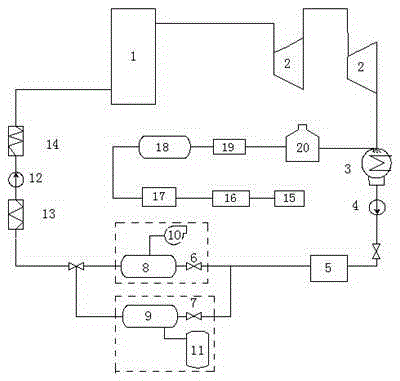

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] Such as figure 1 As shown, the present invention includes a boiler 1, a steam turbine 2 and a condenser 3 connected in sequence. The steam from the boiler 1 is condensed into condensed water after the steam turbine 2 does work. The condensed water flows out from the condenser 3 and enters the fine treatment equipment 5 through the condensed water pump 4. The treated water is sent by the membrane degasser 8 or Membrane oxygenator 9 degasses or adds oxygen to feed water, and both membrane degasser 8 and membrane oxygenator 9 are fiber membrane contactors, wherein membrane degasser 8 is connected with vacuum pump 10, and membrane oxygenator 9 links to each other with oxygen bottle 11. The degassed / oxygenated water is sent to the boiler 1 through the low-pressure heater 13, the feed water pump 12, and the high-pressure heater 14 to complete the condensed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com