Fibrous super capacitor possessing high output voltage and manufacturing method thereof

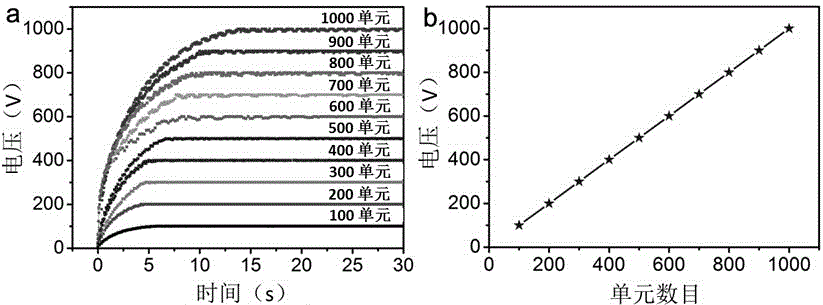

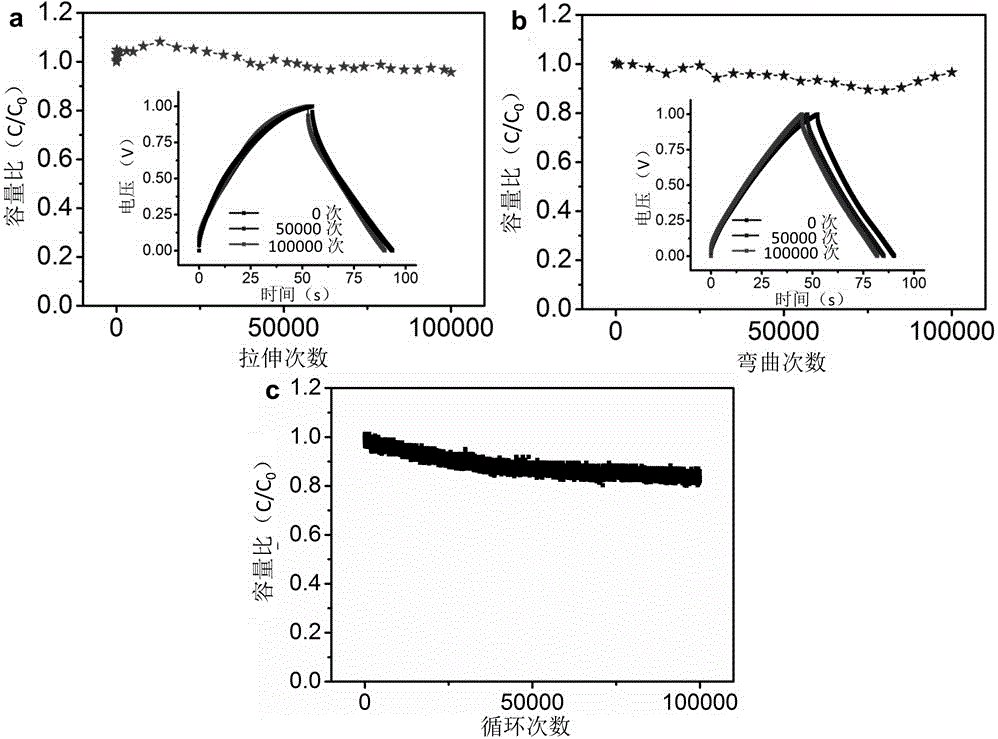

A supercapacitor and fibrous technology, which is applied in the field of fibrous supercapacitors and its preparation, can solve the problems that the maximum working voltage is difficult to meet the voltage requirements, the preparation process is complicated, and the cost is high, achieving good flexibility, simple preparation, and low cost. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

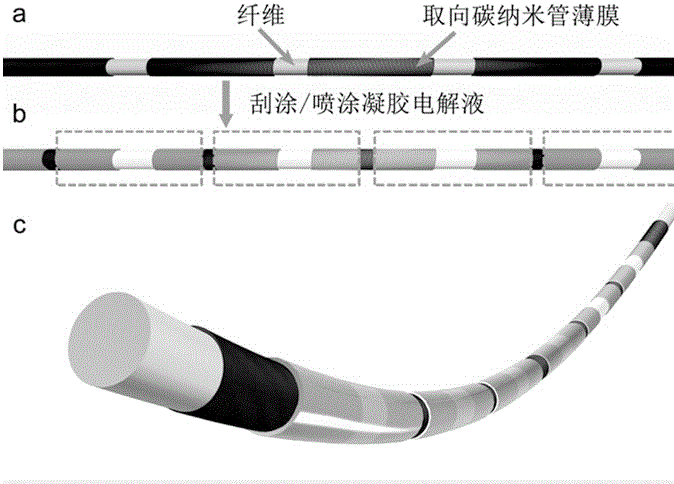

[0014] (1) Spinnable multi-walled carbon nanotube arrays were synthesized by chemical vapor deposition, using Fe(1.2nm) / Al catalysts 2 o 3 (3nm), ethylene is the carbon source, and the mixed gas of argon and hydrogen is the carrier gas;

[0015] (2) On the rotary translation platform, the oriented multi-walled carbon nanotube film with a width of 1.0 cm was continuously wound on the stretchable fibrous substrate at a helix angle of 60°, and repeated twice to obtain A stretchable conductive fiber with a carbon nanotube film thickness of 0.32 μm. The prepared fibers were pre-soaked in an aqueous electrolyte composed of 0.75M / L sulfuric acid and 0.10M / L aniline for 20 minutes, and electrochemically polymerized at a potential of 0.75V with Ag / AgCl as a reference electrode to control polyaniline The mass fraction is 50%, rinsed with deionized water to obtain a carbon nanotube / polyaniline composite electrode;

[0016] (3) Remove the conductive material on the stretchable conducti...

Embodiment 2

[0019] (1) Spinnable multi-walled carbon nanotube arrays were synthesized by chemical vapor deposition, using Fe(1.2nm) / Al catalysts 2 o 3 (3nm), ethylene is the carbon source, and the mixed gas of argon and hydrogen is the carrier gas;

[0020] (2) On the rotary translation platform, the oriented multi-walled carbon nanotube film with a width of 1.0 cm was continuously wound on the stretchable fibrous substrate at a helix angle of 60°, and repeated 20 times to obtain Stretchable conductive fibers with a carbon nanotube film thickness of 3.2 μm. The prepared fibers were pre-soaked in an aqueous electrolyte composed of 0.80M / L sulfuric acid and 0.15M / L aniline for 30 minutes, and electrochemically polymerized at a potential of 0.8V with Ag / AgCl as a reference electrode to control polyaniline The mass fraction is 70%, and rinsed with deionized water to obtain a carbon nanotube / polyaniline composite electrode;

[0021] (3) Remove the conductive material on the stretchable cond...

Embodiment 3

[0024] (1) Spinnable multi-walled carbon nanotube arrays were synthesized by chemical vapor deposition, and the catalyst was Fe(1.5nm) / Al 2 o 3 (4nm), ethylene is the carbon source, and the mixed gas of argon and hydrogen is the carrier gas;

[0025] (2) On the rotary translation stage, wrap the oriented multi-walled carbon nanotube film with a width of 1.0 cm on a stretchable fiber substrate with a diameter of 500 μm, and wind the carbon nanotube film continuously at a helix angle of 60° On a stretchable fibrous substrate, repeat 100 times to obtain a stretchable conductive fiber with a carbon nanotube film thickness of 16 μm;

[0026] (3) Remove the conductive material on the stretchable conductive fiber with a single interval electrode length of 7.2cm and an interval of 0.2cm, and obtain 21 stretchable fiber-shaped fibers with a pitch of 0.2cm and an interval electrode length of 7.2cm on one fiber. electrode;

[0027] (4) Apply the gel electrolyte (mass percentage: 10% p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com