Preparation process for core-shell nanoparticle emulsion for impact modification of aqueous epoxy resin

A water-based epoxy resin and impact-modified technology, which is applied in the field of water-based epoxy resin tougheners, can solve the problems of small improvement in material toughness, large coating layer thickness, and excessive emulsifier dosage, etc., to achieve Reduce the loss of matrix modulus, improve product toughness, and improve the effect of impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

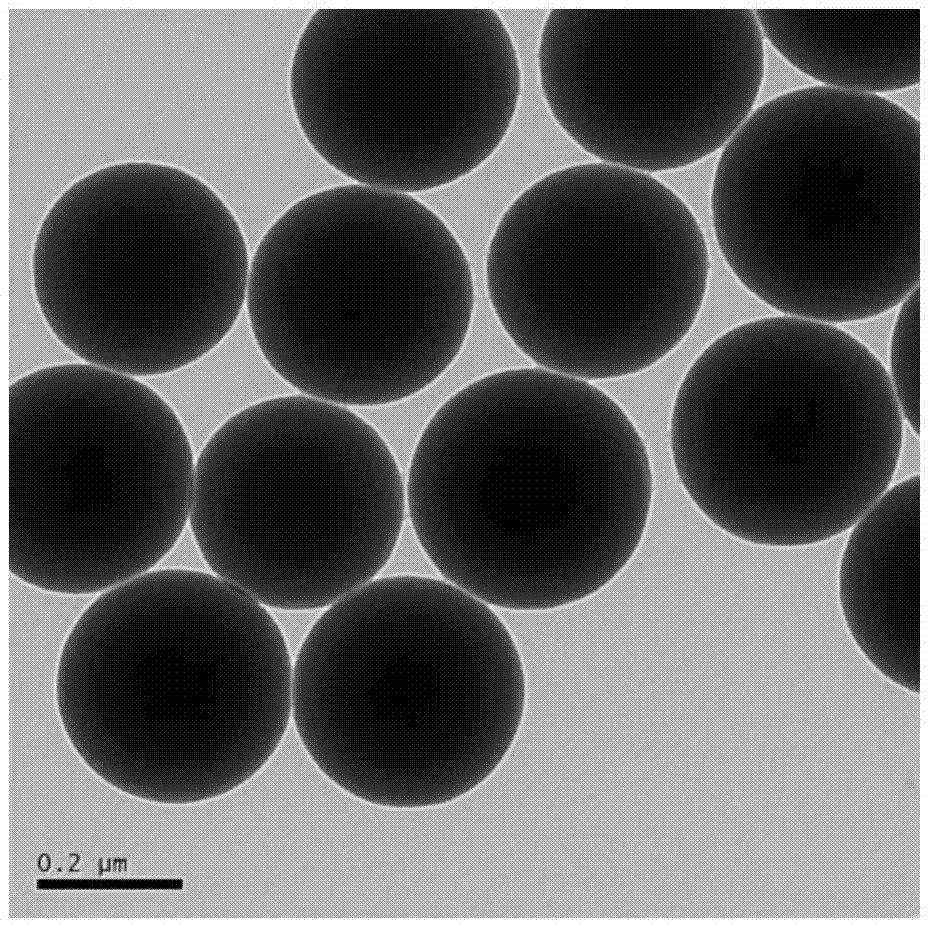

[0049] A. Measure 45 parts of ethanol, 25 parts of deionized water and 10 parts of ammonia water into a reactor with a magnetic stirring device and stir for 10 minutes at a speed of 300 rpm, then increase the speed to 1000 rpm, and measure Mix 15 parts of ethanol and 4.5 parts of tetraethyl orthosilicate evenly, and then quickly drop the mixed solution into the reactor. After the color of the mixed solution in the reactor changes from transparent to milky white, reduce the rotating speed to 300 rpm, keep React at this speed for 4 hours; continue to stir and adjust the temperature to 40-50°C, then add 2 parts of silane coupling agent to the system, keep stirring at the temperature for 24 hours, and then put the dispersion in a 50°C blast drying oven to dry to powder state, and then dried in a vacuum oven at 80°C for 24 hours, then centrifuged and washed with ethanol for 3-4 times, and finally dried to obtain modified hydrophobic nano-silica particles.

[0050] product testing: ...

Embodiment 2

[0059] A. Measure 45 parts of ethanol, 25 parts of deionized water and 10 parts of ammonia water into a reactor with a magnetic stirring device and stir at a speed of 300 rpm for 10 minutes, while measuring 15 parts of ethanol and 4.5 parts of ethyl orthosilicate Mix the esters evenly, then drop the mixture into the reactor with a dropping funnel at a rate of 2ml / min, and react for 4 hours after the dropwise addition; continue to stir and adjust the temperature to 40-50°C, and then add 2 parts of The silane coupling agent is kept at a stirring temperature for 24 hours, centrifuged and washed with ethanol for 3-4 times, and finally dried to obtain modified hydrophobic nano-silica particles.

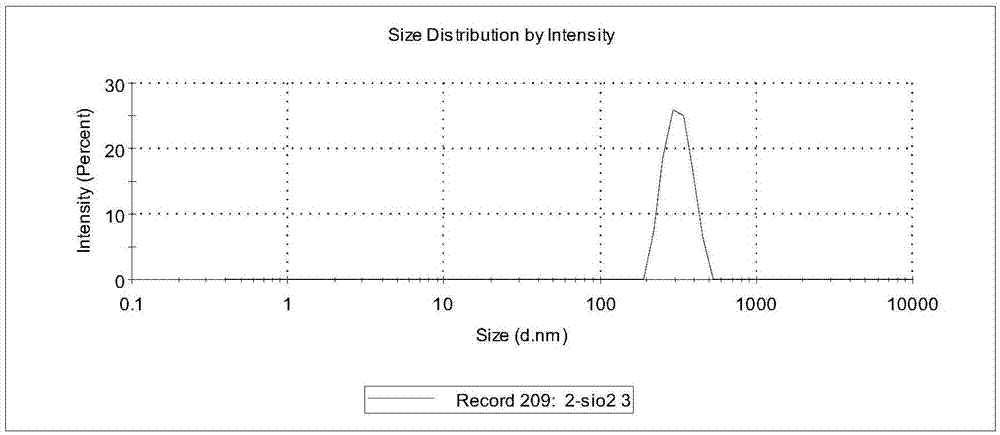

[0060] product testing:

[0061] 1. Electron microscope test, take 0.02g of the nano-silica particles prepared above into 10ml of absolute ethanol, ultrasonically disperse for 30 minutes, and then drop them on the silicon wafer, and observe with the scanning electron microscope after the e...

Embodiment 3

[0067] A. Measure 45 parts of ethanol, 30 parts of deionized water and 10 parts of ammonia water into a reactor with a magnetic stirring device and stir at a speed of 300 rpm for 10 minutes, then increase the speed to 1000 rpm, and measure Mix 15 parts of ethanol and 3 parts of tetraethyl orthosilicate evenly, and then quickly drop the mixed solution into the reactor. After the color of the mixed solution in the reactor changes from transparent to milky white, reduce the rotating speed to 300 rpm, keep React at this speed for 4 hours; continue to stir and adjust the temperature to 40-50°C, then add 2 parts of silane coupling agent to the system, keep stirring at the temperature for 24 hours, and then put the dispersion in a 50°C blast drying oven to dry to powder state, and then dried in a vacuum oven at 80°C for 24 hours, then centrifuged and washed with ethanol for 3-4 times, and finally dried to obtain modified hydrophobic nano-silica particles;

[0068] B. Add 400 parts of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com