Long-life aluminum and alloy oil removing activating solution and application

A long-life, solution-based technology, applied in the field of metal surface treatment, can solve problems such as affecting thermal efficiency, increasing costs, and cleaning difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Part name: aluminum alloy blade of a compressor, material grade: LD2 aluminum alloy

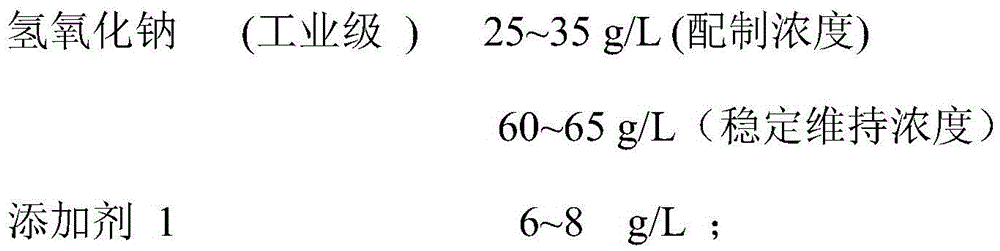

[0053] Composition and process parameters of degreasing and activating bath solution:

[0054]

[0055]

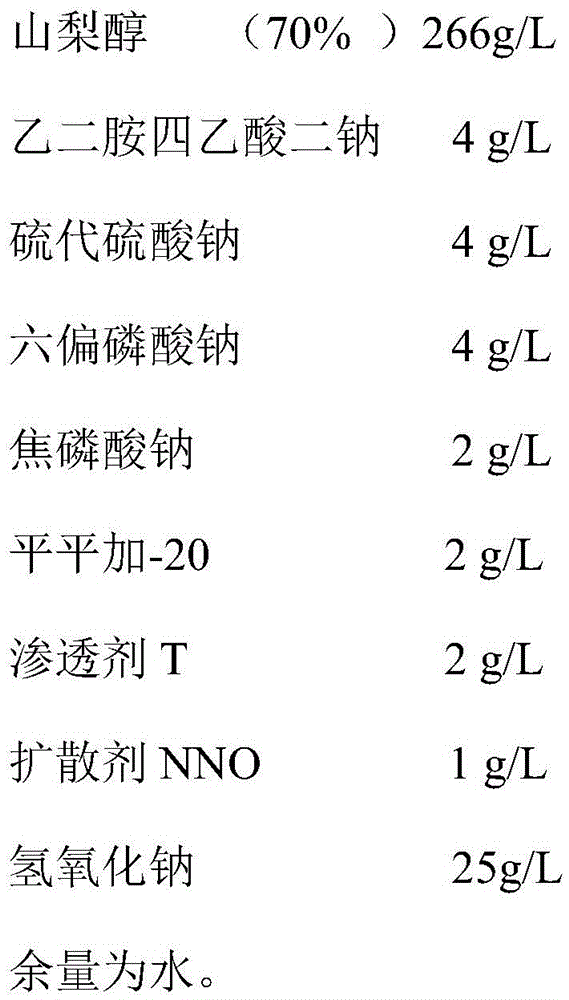

[0056] The composition of Additive 1 is as follows:

[0057]

[0058] The application of a long-life aluminum and its alloy degreasing activation solution is carried out according to the following steps: Add the additive 1 involved in the present invention to the original 25-35g / L sodium hydroxide solution, and the working temperature is 45-60°C , the activation time of aluminum alloy parts in it is 5 minutes; after leaving the tank, the parts should be rinsed in hot water for 1 to 2 minutes; then cleaned in flowing cold water; after that, follow-up anodic oxidation or other coating processing can be carried out according to the normal process .

[0059] Reach dynamic equilibrium when aluminum ion accumulates to 130 grams in this bath solution. That is, the total amount...

Embodiment 2

[0062] Part name: Material grade: LD316063 aluminum alloy is a low alloyed Al-Mg-Si series high plasticity alloy

[0063] Composition and process parameters of degreasing and activating bath solution:

[0064]

[0065] The composition of Additive 2 is as follows:

[0066]

[0067]

[0068] The application of a long-life aluminum and its alloy degreasing activation solution is carried out according to the following steps: in the original sodium hydroxide solution, add 5-7 g / L of the additive involved in the present invention, the working temperature is 55-60 ° C, the aluminum The alloy parts are activated in it for 5 minutes; after leaving the tank, the parts should be rinsed in hot water for 1-2 minutes; then cleaned in flowing cold water; after that, subsequent anodic oxidation or other coating processes can be carried out according to the normal process.

[0069] The bath solution reaches a dynamic equilibrium when the aluminum ions accumulate to 138-140 g / L. That...

Embodiment 3

[0072] Part name: Material grade: 3A21 aluminum alloy (imitation stainless steel color) aluminum alloy for engine accessories

[0073] Composition and process parameters of degreasing and activating bath solution:

[0074]

[0075] The composition of Additive 3 is as follows:

[0076]

[0077]

[0078] The application of a long-life aluminum and its alloy degreasing activation solution is carried out according to the following steps: add the additive 3 involved in the present invention to the original sodium hydroxide solution, the working temperature is 45-60 °C, and the aluminum alloy parts are in it The activation time is 3 minutes; after leaving the tank, the parts should be rinsed in hot water for 1-2 minutes; then cleaned in flowing cold water; after that, follow-up anodic oxidation or other coating processes can be carried out according to the normal process.

[0079] The bath solution reaches a dynamic equilibrium when the aluminum ions accumulate to 138-140 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com