Preparation method of edible oil suspension gel beverage

A manufacturing method and edible oil technology, applied in the direction of food science, etc., can solve the problems of high processing conditions, easy oxidation of active ingredients, inconvenient consumption of capsules, etc., low threshold, high utilization rate of human digestion and absorption, edible and save the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

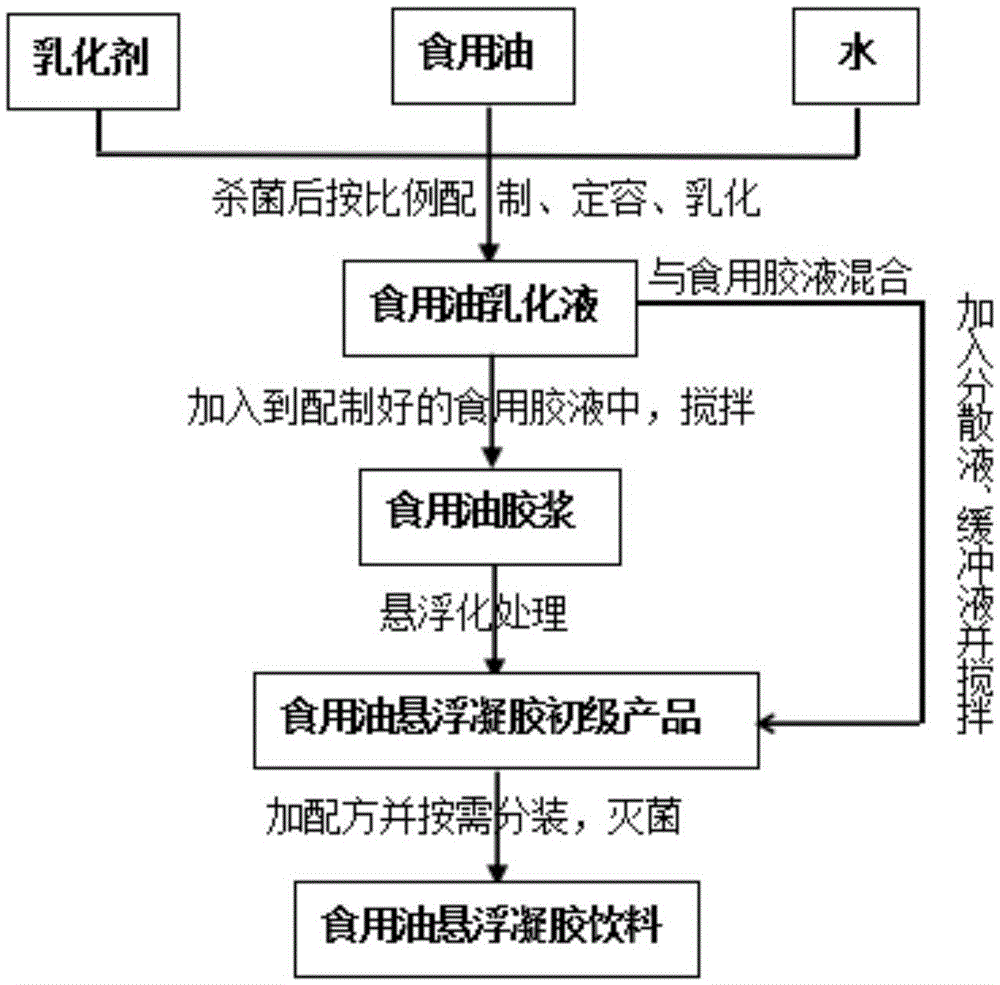

[0035] Embodiment 1: as figure 1 as shown,

[0036] A kind of manufacture method of edible oil suspension gel beverage, its main steps are as follows:

[0037]1) Edible oil emulsification: the emulsifier (selection of soybean lecithin, sucrose ester, sodium alginate, xanthan gum, modified corn starch, carboxymethyl cellulose, monoglyceride, the ratio between them is: 1 :0.6:0.3:1:0.1:0.01:0.1, the amount of emulsifier or emulsifier combination in the emulsion is 0.05%, and the emulsification temperature is 35°C), edible oil (astaxanthin oil and olive oil) and water After steam sterilization, preparation in proportion, and constant volume, carry out in an emulsification tank, use a rotary or turbine mixer to quickly stir and emulsify, the stirring speed is 500 rpm, and the stirring time is 1 minute to obtain an edible oil emulsion;

[0038] 2) Combine the edible oil emulsion obtained in step 1) with the prepared and sterilized edible glue (guar gum, locust bean gum, xanthan g...

Embodiment 2

[0046] A kind of manufacture method of edible oil suspension gel beverage, its main steps are as follows:

[0047] 1) Edible oil emulsification: the emulsifier (selection of soybean lecithin, sucrose ester, sodium alginate, xanthan gum, modified corn starch, carboxymethyl cellulose, monoglyceride, the ratio between them is: 3 :2:2:3:6:3:3, the amount of emulsifier or combination of emulsifiers added to the emulsion is 2%, and the emulsification temperature is 50°C), edible oil (astaxanthin oil, olive oil, castor oil, Rapeseed oil (can be a combination of one or two or more) and water are sterilized by ultrasonic waves and prepared in proportion, and after constant volume, carry out in an emulsification tank, and use a rotary or turbine mixer to quickly stir and emulsify. The stirring speed is 10000 rpm, and the stirring time is 15 minutes to obtain edible oil emulsion;

[0048] 2) Combine the edible oil emulsion obtained in step 1) with the prepared and sterilized edible glue...

Embodiment 3

[0057] A kind of manufacture method of edible oil suspension gel beverage, its main steps are as follows:

[0058] 1) Edible oil emulsification: the emulsifier (selection of soybean lecithin, sucrose ester, sodium alginate, xanthan gum, modified corn starch, carboxymethyl cellulose, monoglyceride, the ratio between them is: 7 :5:4:5:12:7:6, the amount of emulsifier or combination of emulsifiers added to the emulsion is 3%, and the emulsification temperature is 65°C), edible oil (astaxanthin oil, olive oil, camellia oil) After the water and water are sterilized by steam, prepared in proportion and fixed to volume, they are carried out in an emulsification tank, and a rotary or turbine mixer is used for rapid stirring and emulsification. The stirring speed is 20,000 rpm and the stirring time is 30 minutes to obtain edible oil. Emulsion;

[0059] 2) Combine the edible oil emulsion obtained in step 1) with the prepared and sterilized edible glue (guar gum, locust bean gum, xantha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com