Heteroatom-doped carbon-load iron carbide/ molybdenum or tungsten carbide catalyst and preparation method and application thereof

A heteroatom, iron carbide technology, applied in the field of catalyst preparation, can solve the problems of active center troublesome synthesis, low density, etc., and achieve the effects of excellent electrocatalytic performance, uniform distribution, and easy process control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

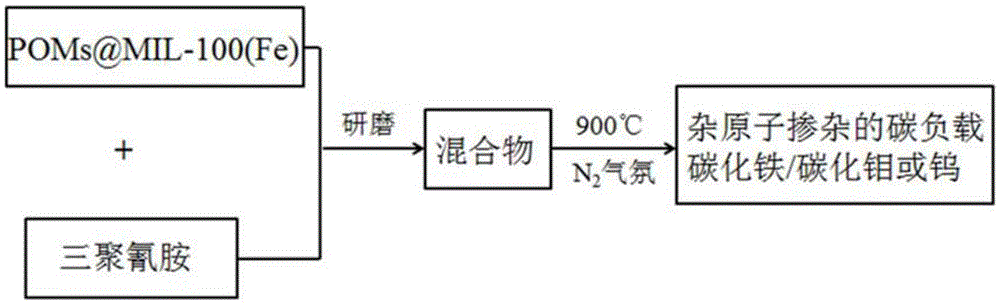

[0027] Preparation of POMsMIL-100(Fe): Dissolve 3.2g of phosphomolybdic acid and 1.89g of ferric chloride hexahydrate in 50mL of distilled water, add 1.36g of trimethyl 1,3,5-benzene trihydroxyester, After reacting at ℃ for 72 hours, the obtained product was separated by centrifugation, and washed with ethanol and ether respectively.

[0028] The preparation method of heteroatom-doped carbon-supported iron carbide / molybdenum carbide samples: mix and grind POMsMIL-100(Fe) and melamine (1:3); , pickling, to obtain the final desired sample.

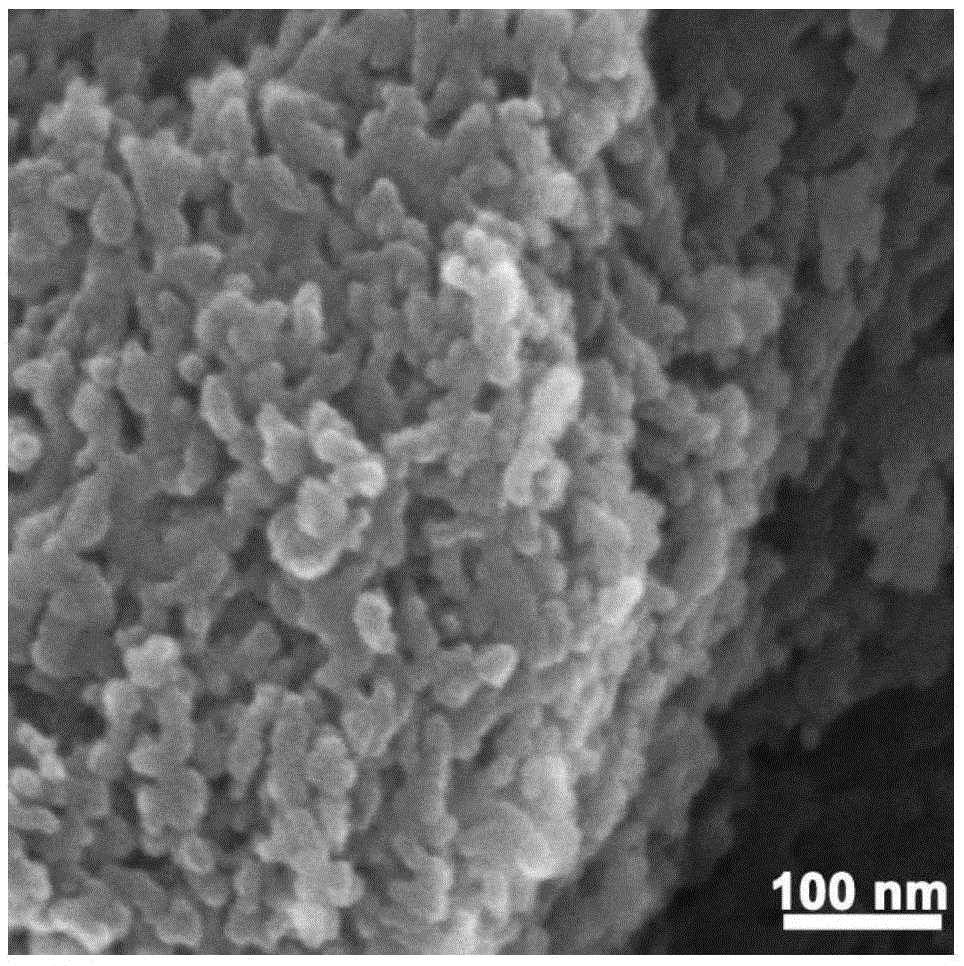

[0029] The TEM photos of the obtained samples are shown in Fig. 3(a)-(b), from which it can be seen that the prepared nanoparticles are relatively small in size and evenly distributed. Its electrolytic water hydrogen production (hydrogen evolution) performance is: the initial potential is 18mV (relative to the standard hydrogen electrode), and the Tafel slope is 45.2mVdec -1 , Continuous operation 10h still maintains good stability.

Embodiment 2

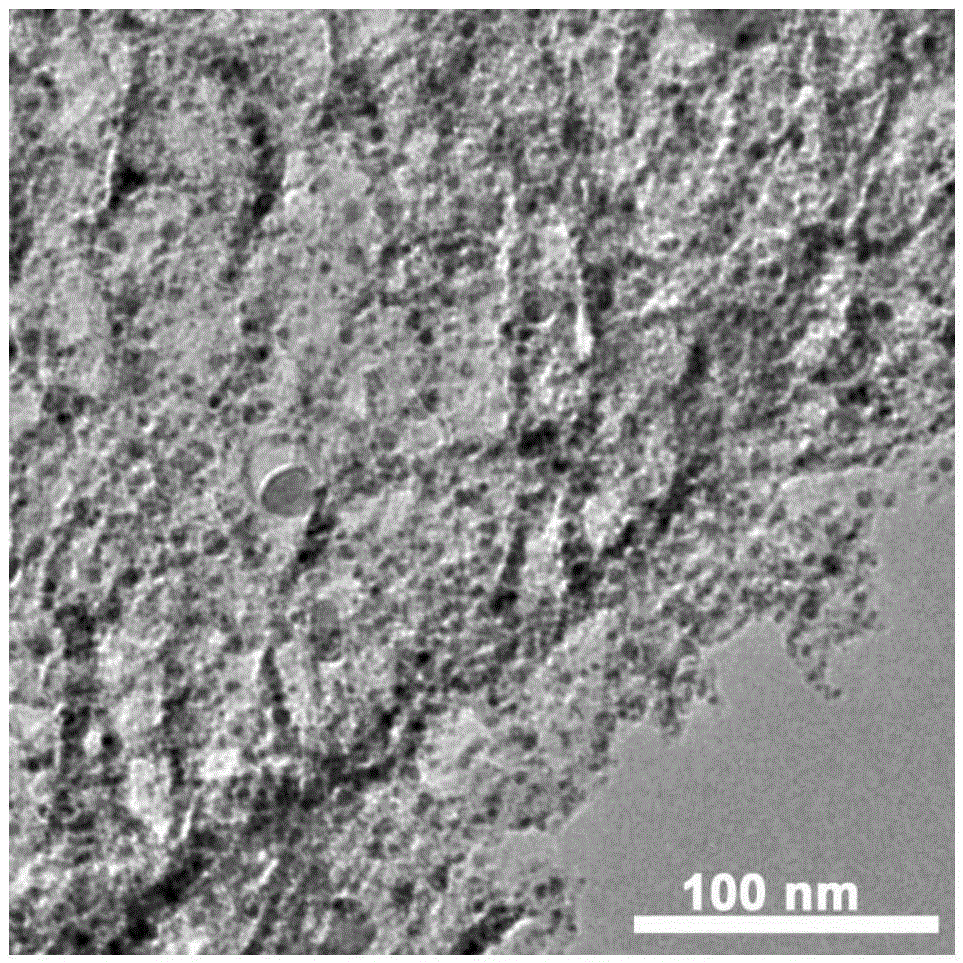

[0031] The preparation process and steps in this example are basically the same as those in Example 1 above, except that the calcination temperature is adjusted from 900°C to 1000°C. The SEM and TEM photos of the obtained samples are shown in Figure 4(a)-(b). Its electrolytic water hydrogen production (hydrogen evolution) performance is: the initial potential is 80mV (compared to the standard hydrogen electrode), and the Tafel slope is 59.2mVdec -1 , Continuous operation 10h still maintains good stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Onset potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com