Para-aramid fiber and mica composite paper and production method thereof

A technology of para-aramid fiber and para-aramid fiber, which is applied in the direction of synthetic cellulose/non-cellulose material pulp/paper, fiber raw material processing, paper, etc., which can solve the requirements of materials that are difficult to meet the insulation grade of C and above. , It is difficult to meet the problems of high-end field use, limited heat resistance of meta-aramid fibers, etc., to achieve excellent composite reinforcement effect, excellent liquid phase dispersion performance, and the effect of improving mechanical and dielectric strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

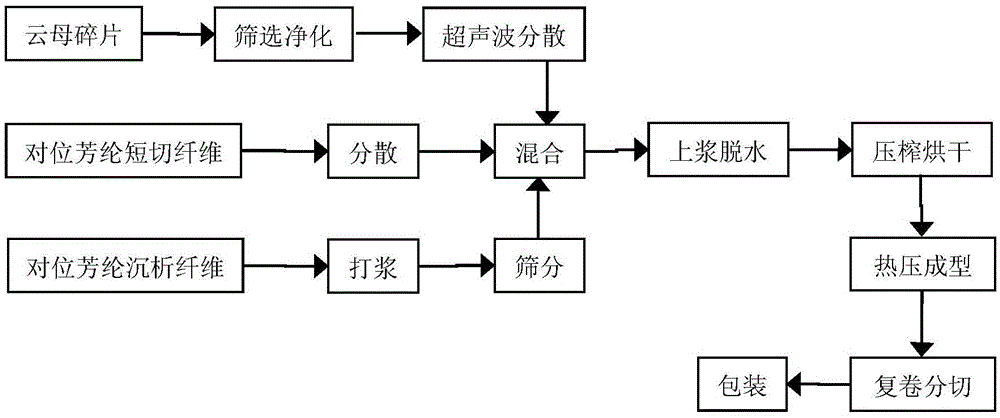

Method used

Image

Examples

preparation example Construction

[0031] (1) Preparation of mica flake slurry: air-select mica fragments, remove impurities such as air-dried mica, rusty mica, stained mica, and sawdust that are not suitable for copying, and further remove fine silt and other impurities through a pressure sieve, and then use a power of 800 ~ 3000W ultrasonic treatment for 1 ~ 10h, the mica fragments are peeled into mica flakes, and the mica flakes are prepared into a slurry with a mass concentration of 1% to 6%;

[0032] (2) Dispersion of para-aramid short-cut fibers: disperse para-aramid short-cut fibers with a length of 4 to 12 mm and a fineness of 2D in water, and add 0.3 to 1% of the dispersant poly Ethylene oxide solution, the mass concentration of the added polyoxyethylene solution is 0.03-0.10%, and the trough beater is used to fully decompose and disperse evenly to obtain para-aramid chopped fiber slurry, and the mass concentration of the slurry is 0.01-0.05%;

[0033] (3) Beating of the para-aramid fibrids: the para-a...

Embodiment 1

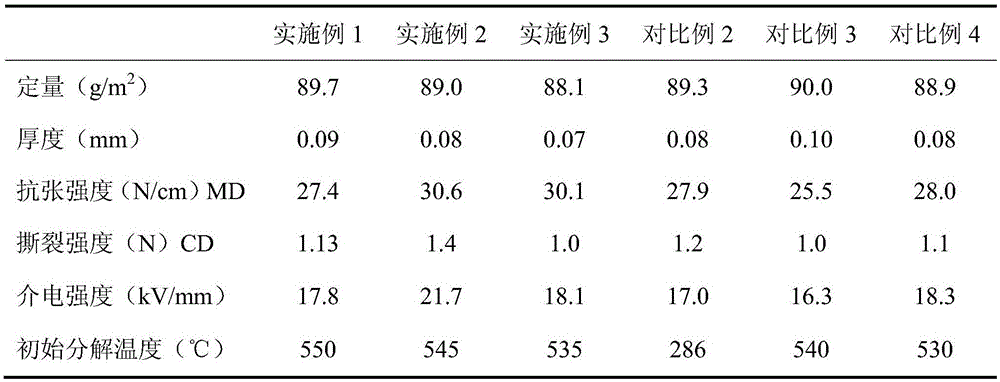

[0037] Embodiment 1 adopts the method of the present invention to prepare para-aramid fiber mica composite paper

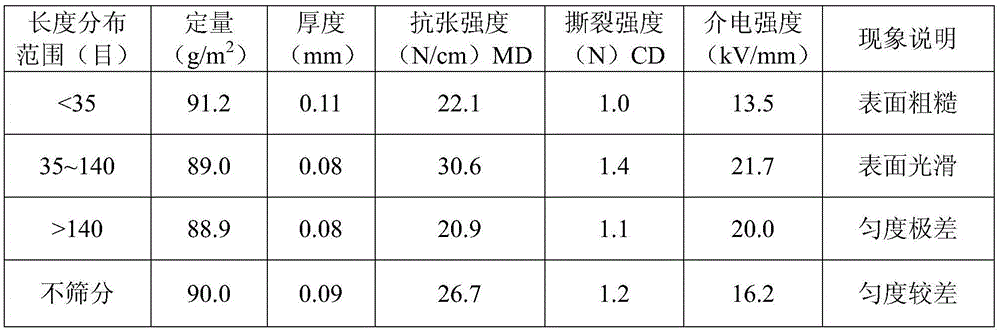

[0038]Select muscovite fragments with a thickness ≤ 1.6mm, remove impurities through winnowing and pressure sieving, and use ultrasonic treatment to peel the muscovite fragments into mica flakes, with a power of 800W and a time of 10h, and prepare a slurry with a mass concentration of 1%. ; Use a trough-type beater to disperse the para-aramid chopped fibers with a length of 12mm and a fineness of 2D. Before dispersing, add 0.3% polyethylene oxide relative to the absolute dry mass, and the mass concentration of the polyethylene oxide solution is 0.03%. Aramid chopped fiber slurry, the mass concentration of the slurry is 0.01%; the para-aramid precipitated fiber is beaten by a disc refiner, the beating degree is 40°SR, and the length distribution is selected by a sieving instrument from 35 to 140 mesh pairs Para-aramid precipitated fiber, prepared into para-aramid p...

Embodiment 2

[0039] Embodiment 2 adopts the method of the present invention to prepare para-aramid fiber mica composite paper

[0040] Select muscovite fragments with a thickness ≤ 1.6mm, remove impurities through winnowing and pressure sieving, and use ultrasonic treatment to peel the muscovite fragments into mica flakes, with a power of 1500W and a time of 5h, and prepare a slurry with a mass concentration of 3%. ; Use a trough-type beater to disperse the para-aramid chopped fibers with a length of 6mm and a fineness of 2D. Before dispersing, add 0.5% polyethylene oxide relative to the absolute dry mass, and the mass concentration of the polyethylene oxide solution is 0.05%, and the para-aramid fiber is obtained. Aramid chopped fiber slurry, the slurry mass concentration is 0.03%; the para-aramid precipitated fiber is beaten with a disc refiner, the beating degree is 50°SR, and the length distribution of 35-140 mesh pairs is selected by a sieving instrument Para-aramid fibrid fiber, prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com