Lithium-ion battery NiCrxOy negative electrode material and preparation method thereof

A technology of lithium-ion batteries and negative electrode materials, which is applied in the field of electrochemical power sources, can solve the problems of unreported electrochemical performance, and achieve the effects of easy operation, high material capacity and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

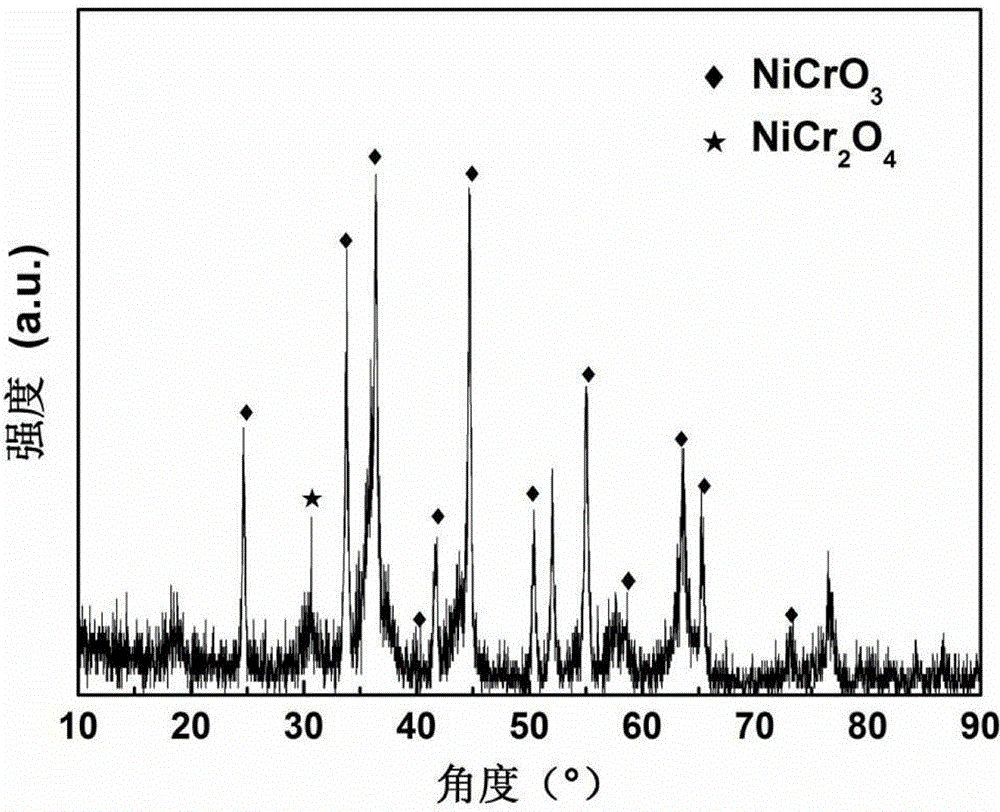

[0030] Weigh nickel nitrate, chromium nitrate nonahydrate and hexamethylenetetramine in a molar ratio of 1:1:2 to accurately weigh the drug, put it in a beaker, add 40ml of distilled water and stir evenly, then transfer to a hydrothermal reaction kettle at 160°C After reacting for 24 hours, the reaction product was centrifuged and washed three times alternately with deionized water and ethanol, and then transferred to a petri dish for drying. Place the dried precursor in a crucible or a quartz boat, and move the crucible or quartz boat into a high-temperature tube furnace, calcinate at 450°C for 9 hours in the air, and naturally cool to obtain NiCrO 3 sample. The results showed that the prepared samples were analyzed by XRD patterns ( figure 1 ) analyzed as NiCrO 3 , corresponding to the XRD card JCPDS, No. 22-0748. In addition, there are heterogeneous NiCr 2 o 4 exists, corresponding to the XRD card JCPDS, No. 54-0961.

Embodiment 2

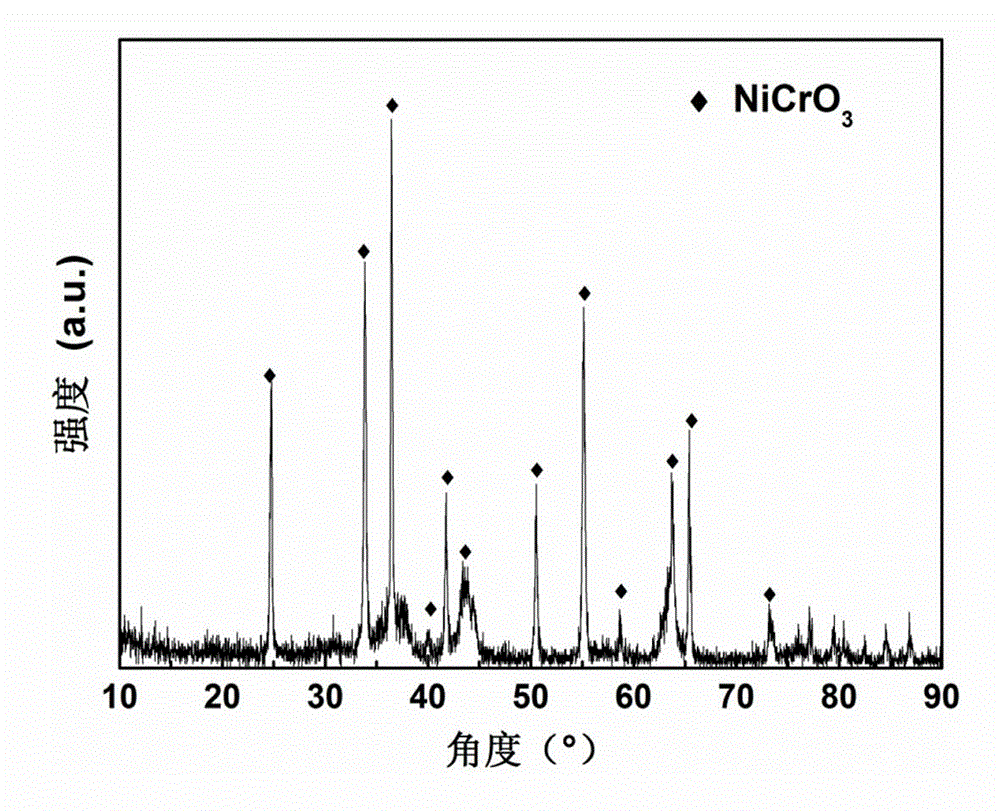

[0032] Weigh nickel nitrate, chromium nitrate nonahydrate and hexamethylenetetramine in a molar ratio of 1:2:3 to accurately weigh the drug, put it in a beaker, add 40ml of distilled water and stir evenly, then transfer it to a hydrothermal reaction kettle at 100°C After reacting for 12 hours, the reaction product was washed by centrifugation, washed alternately with deionized water and ethanol three times, and then transferred to a petri dish for drying. Place the dried precursor product in a crucible or a quartz material boat, and move the crucible or quartz boat into a high-temperature tube furnace, calcinate at 500°C for 5 hours in air, and naturally cool to obtain NiCrO 3 sample. through figure 2 XRD results analysis showed that the prepared samples were pure NiCrO 3 , corresponding to the XRD card JCPDS, No. 22-0748. at 24.6 o , 33.8 o , 36.4 o 、40 o , 41.8 o , 44.5 o , 50.6 o , 55.2 o , 58.8 o , 63.9 o , 65.6 o and 73.5 o The diffraction peaks correspond...

Embodiment 3

[0034] Weigh nickel nitrate, chromium nitrate nonahydrate and hexamethylenetetramine in a molar ratio of 1:3:5 to accurately weigh the drug, put it in a beaker, add 40ml of distilled water and stir evenly, then transfer it to a hydrothermal reaction kettle at 200°C After reacting for 48 hours, the reaction product was washed by centrifugation, washed alternately with deionized water and ethanol three times, and then transferred to a petri dish for drying. Place the dried product obtained in a crucible or a quartz material boat, and move the crucible or quartz boat into a high-temperature tube furnace, calcinate at 550°C for 3 hours in the air, and naturally cool to obtain NiCrO 3 sample. The results showed that the prepared samples were analyzed by XRD patterns ( Figure 5 ) analyzed as NiCrO 3 , corresponding to the XRD card JCPDS, No. 22-0748. It can be seen from the XRD spectrum that there is a small amount of NiO impurities, corresponding to the XRD card JCPDS, No.73-15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com