Method for chemical nickel-plating on surface of cement-based piezoelectric composite

A piezoelectric composite material and surface chemistry technology, which is applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve the problems of affecting the stability of the plating solution, strong particle catalytic activity, and unsuitable nickel plating. Achieve the effect of low cost, tight combination of grains and uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] For above 8×8mm 2 , the surface of the cement-based piezoelectric composite material with a thickness of 2mm is nickel-plated, and the steps are as follows:

[0054] Step 1: Grinding and degreasing the surface of the cement-based piezoelectric composite material to be plated:

[0055] Grind the cement-based piezoelectric composite material to be plated with 600# and 1000# sandpaper in sequence, and then finely polish it with metallographic sandpaper. After ultrasonic cleaning for 10 minutes, immerse it in a degreasing solution containing acetone and ultrasonically clean it for 20 minutes.

[0056] Step 2: Surface roughening of the cement-based piezoelectric composite material to be plated:

[0057] Put the degreased cement-based piezoelectric composite material in the roughening solution for roughening, treat it at 30°C for 30 minutes, and then rinse it with water to remove the roughening solution. The preparation method of the coarsening solution is: mix sodium hydro...

Embodiment 2

[0072] For above 8×8mm 2 , the surface of the cement-based piezoelectric composite material with a thickness of 2mm is nickel-plated, and the steps are as follows:

[0073] Step 1: Same as Example 1.

[0074] Step 2: Same as Example 1.

[0075] Step 3: Reduction treatment of the cement-based piezoelectric composite material substrate to be plated:

[0076] Put the roughened cement-based piezoelectric composite into the reducing solution and soak for 10 min at room temperature.

[0077] Step 4: Activation treatment of the cement-based piezoelectric composite material substrate to be plated:

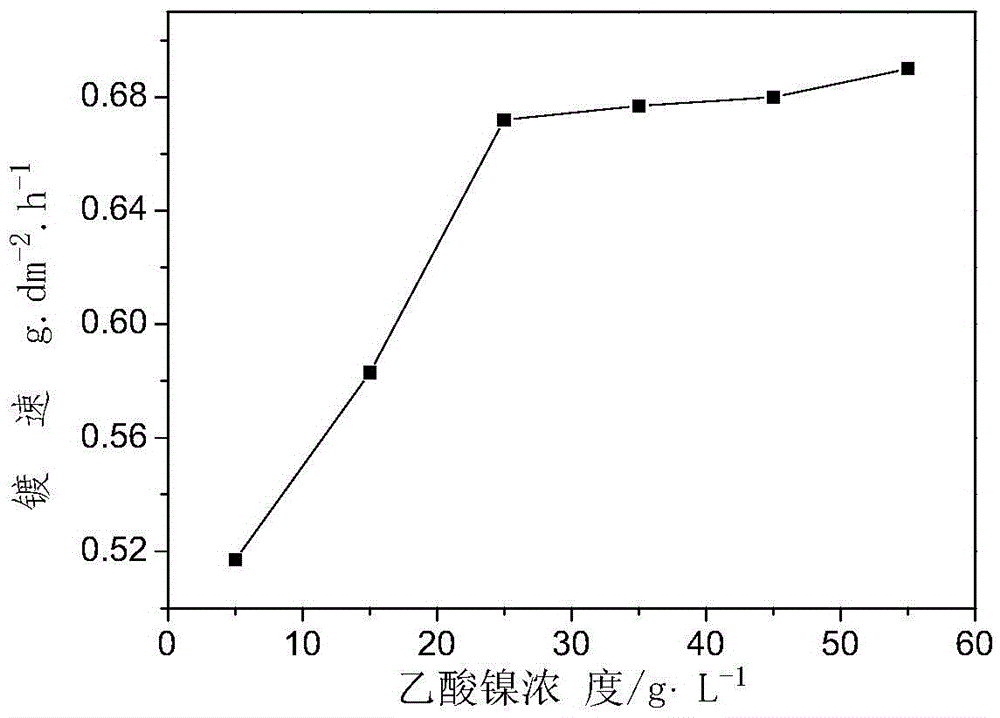

[0078] The reduced cement-based piezoelectric composite material was taken out and immersed in the activation solution, soaked at 35°C for 10 minutes, so that nickel ions could be reduced to elemental nickel and adsorbed on the surface of the substrate, and rinsed with water. The activation solution is an aqueous solution of nickel acetate, and the content of nickel acetate is 25g / L. ...

Embodiment 3

[0086] For above 8×8mm 2 , the surface of the cement-based piezoelectric composite material with a thickness of 2mm is nickel-plated, and the steps are as follows:

[0087] Step 1: Same as Example 1.

[0088] Step 2: Same as Example 1.

[0089] Step 3: Same as Example 1.

[0090] Step 4: Activation treatment of the cement-based piezoelectric composite material substrate to be plated:

[0091] Take the reduced cement-based piezoelectric composite material out and immerse it in the activation solution, and soak it at 35°C for 10 minutes, so that nickel ions can be reduced to simple nickel and adsorbed on the surface of the substrate, and rinsed with water after activation.

[0092] Step 5: Same as Example 1.

[0093] In the above step 4, the activation solution is an aqueous solution of nickel acetate or nickel sulfate, and the content of nickel acetate or nickel sulfate is 25g / L.

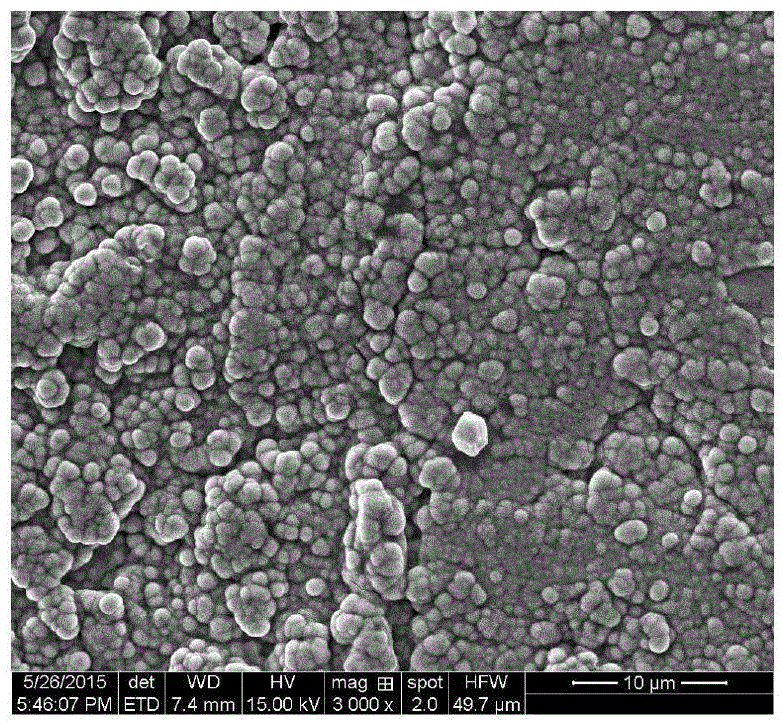

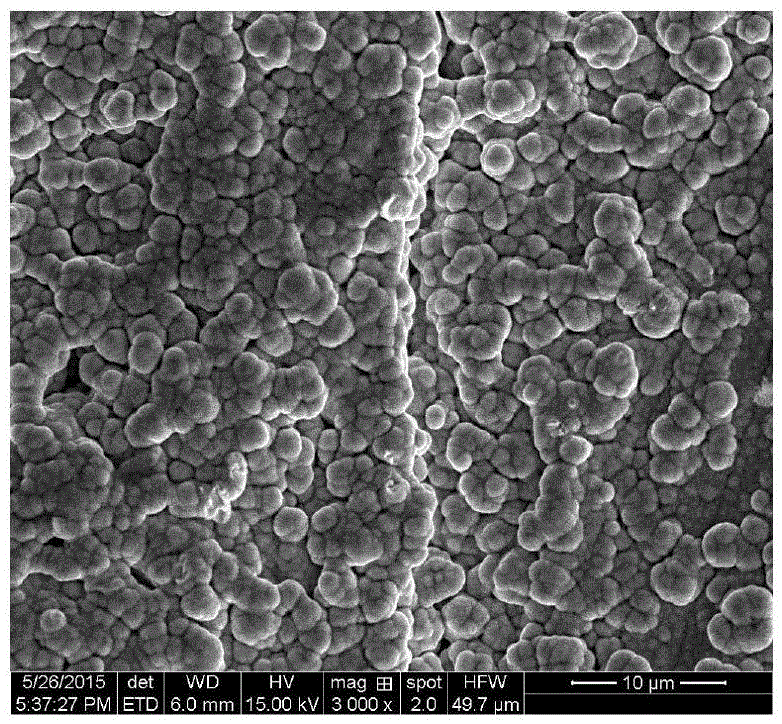

[0094] The coatings obtained by nickel acetate and nickel sulfate have bright and smooth sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com