Preparation method for nano-granular Mn3O4/Super P lithium ion battery negative electrode material

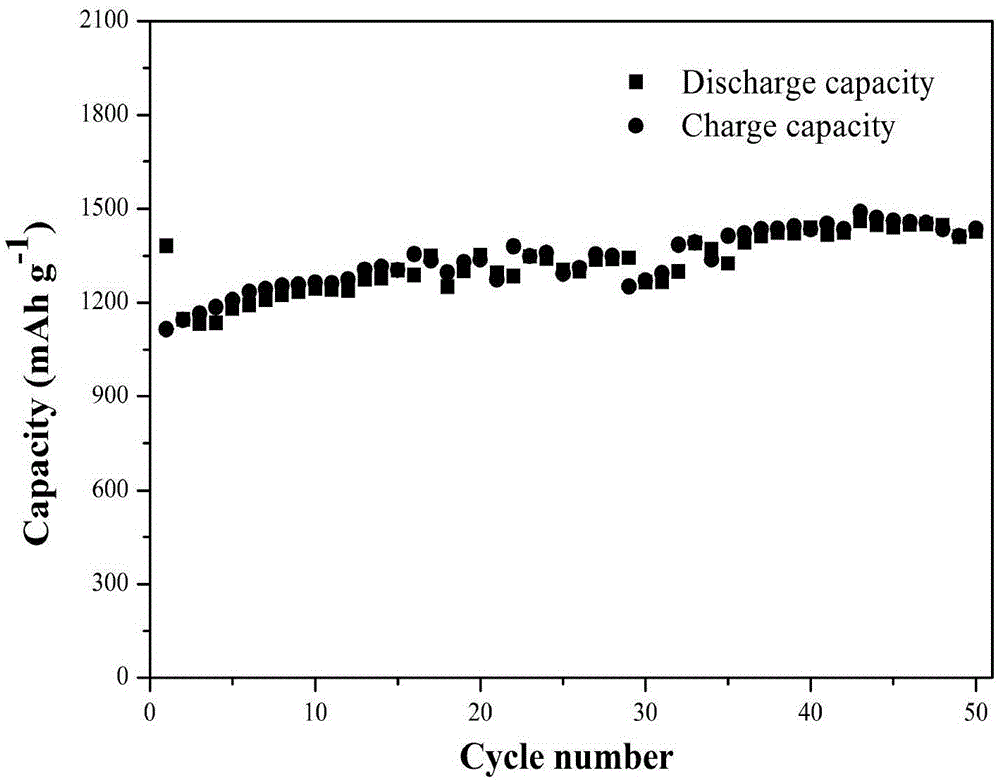

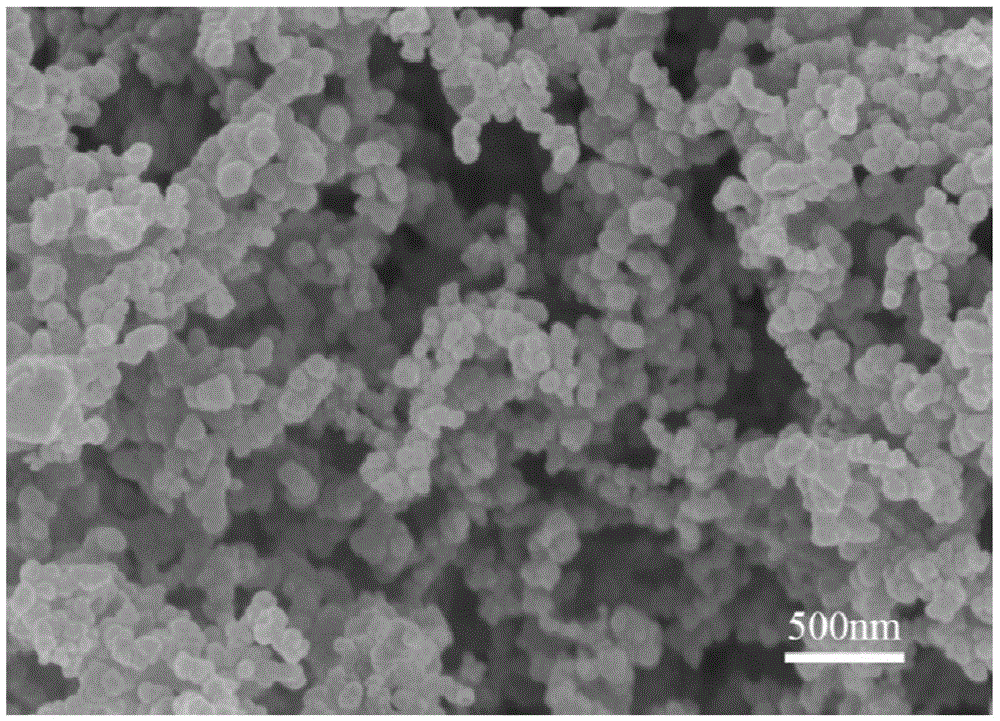

A technology for lithium ion batteries and negative electrode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as unsuitability for large-scale industrial production and complex preparation process of carbon quantum dots, achieve good cycle stability, improve electrical Chemical properties, high capacity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

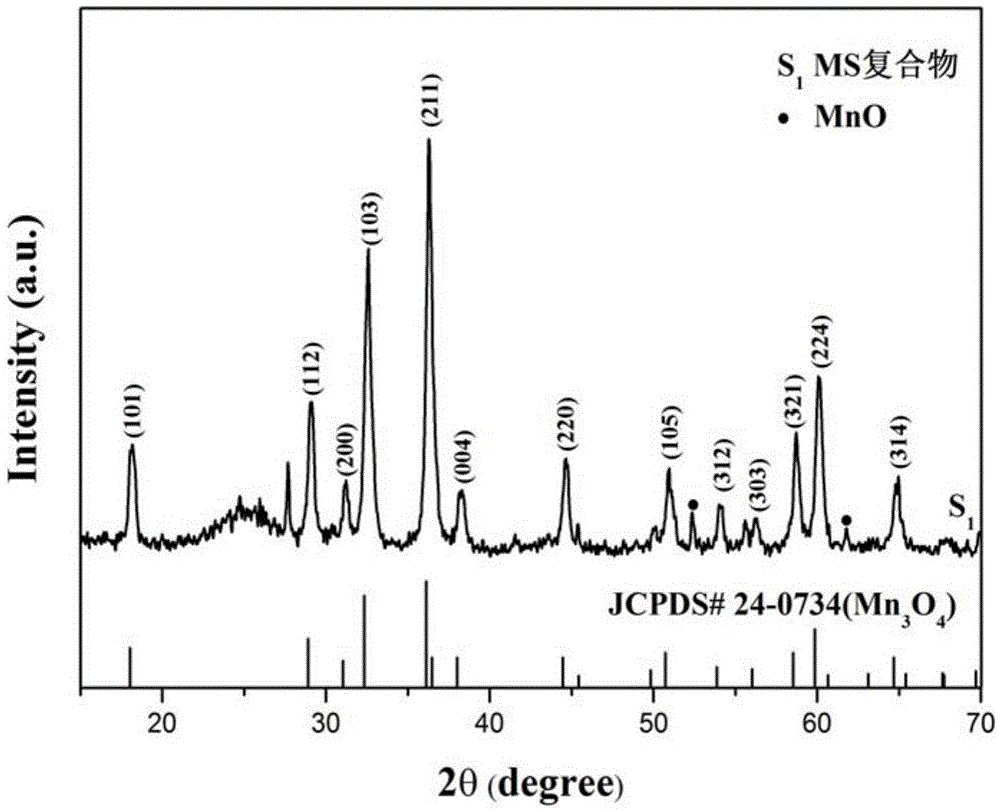

Embodiment 1

[0022] 1) Potassium permanganate and manganese chloride tetrahydrate were added into water respectively according to the ratio of substances of 2:3 to prepare a potassium permanganate solution of 1.25% and a solution of manganese chloride tetrahydrate of 2.25% by mass fraction, and Mix, stir magnetically at room temperature, and filter to obtain manganese dioxide precipitation;

[0023] 2) washing the manganese dioxide precipitate with deionized water until the washing liquid is neutral and drying to obtain manganese dioxide powder;

[0024] 3) Mix manganese dioxide powder and SuperP uniformly in a mass ratio of 3:1 to obtain a mixed material;

[0025] 4) heat-treating the mixed material at 400° C. for 5 h in an argon atmosphere to obtain a solid battery negative electrode material.

Embodiment 2

[0027] 1) Potassium permanganate and manganese chloride tetrahydrate were added into water according to the ratio of substances of 2:3 to prepare potassium permanganate solution of 2.5% and manganese chloride tetrahydrate solution of 4% by mass fraction, and Mix, stir magnetically at room temperature, and filter to obtain manganese dioxide precipitation;

[0028] 2) washing the manganese dioxide precipitate with deionized water until the washing liquid is neutral and drying to obtain manganese dioxide powder;

[0029] 3) Mix manganese dioxide powder and SuperP uniformly in a mass ratio of 2:1 to obtain a mixed material;

[0030] 4) heat-treating the mixed material at 600° C. for 2 h in an argon atmosphere to obtain a solid battery negative electrode material.

Embodiment 3

[0032] 1) Potassium permanganate and manganese chloride tetrahydrate were added into water according to the ratio of substances of 2:3 to prepare potassium permanganate solution and 3% manganese chloride tetrahydrate solution with a mass fraction of 1.5%, and Mix, stir magnetically at room temperature, and filter to obtain manganese dioxide precipitation;

[0033] 2) washing the manganese dioxide precipitate with deionized water until the washing liquid is neutral and drying to obtain manganese dioxide powder;

[0034] 3) Mix manganese dioxide powder and SuperP uniformly in a mass ratio of 1:1 to obtain a mixed material;

[0035] 4) The mixed material was heat-treated at 500° C. for 3.5 h in an argon atmosphere to obtain a solid battery negative electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com