Porous-carbon loaded metal composite material and preparing method and application thereof

A composite material and metal-loaded technology, applied in the field of nanomaterials, can solve problems such as poor activity and stability, and achieve the effects of low cost, excellent performance, and easy large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] Correspondingly, an embodiment of the present invention provides a method for preparing a porous carbon-supported metal composite material, comprising the following steps:

[0044] NiMoO 4 Nanorods and carbon source monomers were reacted in Tris reagent solution to obtain NiMoO 4 / carbon source precursor;

[0045] The NiMoO 4 / The carbon source precursor is calcined to obtain a porous carbon-supported metal composite material;

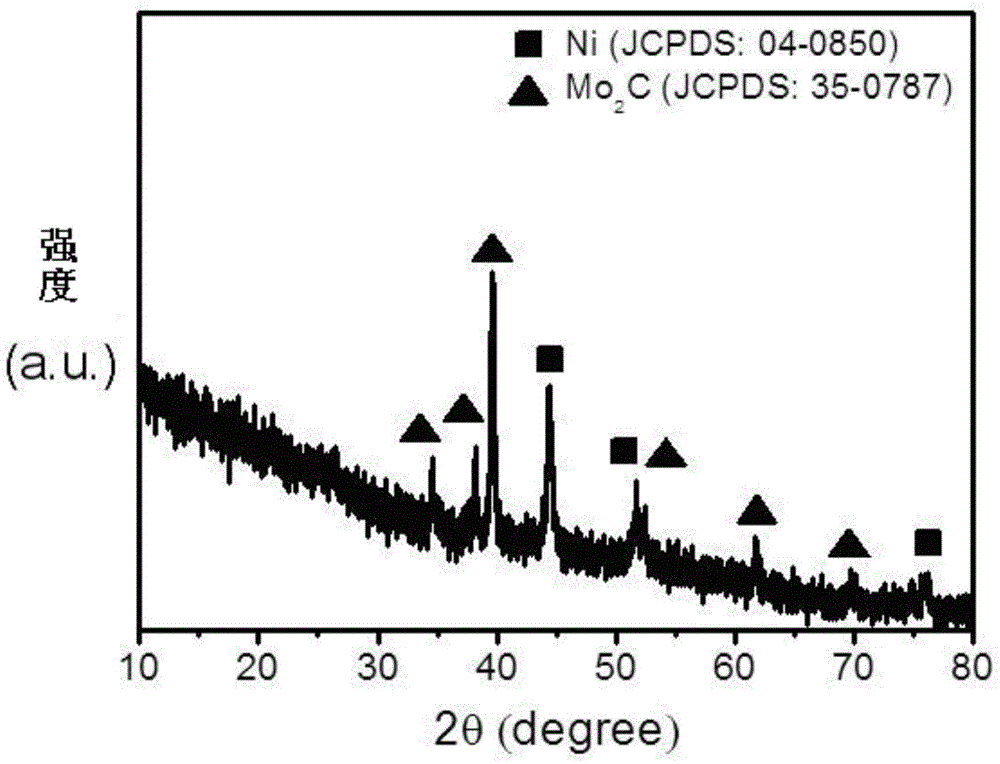

[0046] The composite material includes: a porous carbon support; and nickel and molybdenum carbide supported on the porous carbon support.

[0047] The preparation method provided by the invention can prepare porous carbon-loaded nickel and molybdenum carbide composite material, which has high catalytic activity for hydrogen production; and the invention can simplify the process flow, reduce the cost, and is suitable for large-scale industrial promotion.

[0048] The embodiment of the present invention provides NiMoO 4 nanorods, the NiMoO ...

Embodiment 1

[0068] (1)NiMoO 4 Preparation of nanorod material: 2mmolNi(NO 3 ) 2 ·6H 2 O and 2 mmol Na 2 MoO 4 2H 2 O was respectively dissolved in 17.5mL deionized water, stirred and fully dissolved, and the above Na 2 MoO 4 solution was added to Ni(NO 3 ) 2 solution, stirred for 10 minutes to form a uniform mixed solution; transferred the mixed solution to a 50mL reaction kettle, put it in a 150°C oven, and reacted for 6h; took out the reaction kettle to obtain a large amount of yellow precipitate, and centrifuged the obtained reaction mixture. Then wash twice with distilled water and once with ethanol, and dry in a vacuum oven at 60°C for 12 hours.

[0069] (2) Prepare a 2 mg / mL Tris reagent solution, and then use 1 mol / L dilute hydrochloric acid to adjust the pH of the Tris reagent solution to make the pH of the solution 8.5. Take by weighing a certain amount of NiMoO prepared in step (1) 4Nanorods, dispersed into the above Tris reagent solution, NiMoO 4 The mass concentrat...

Embodiment 2

[0074] Example 1 was repeated, with the following difference: when stirring vigorously, the mass concentration of dopamine was 0.2 mg / mL, and a porous carbon-supported metal composite material was finally prepared.

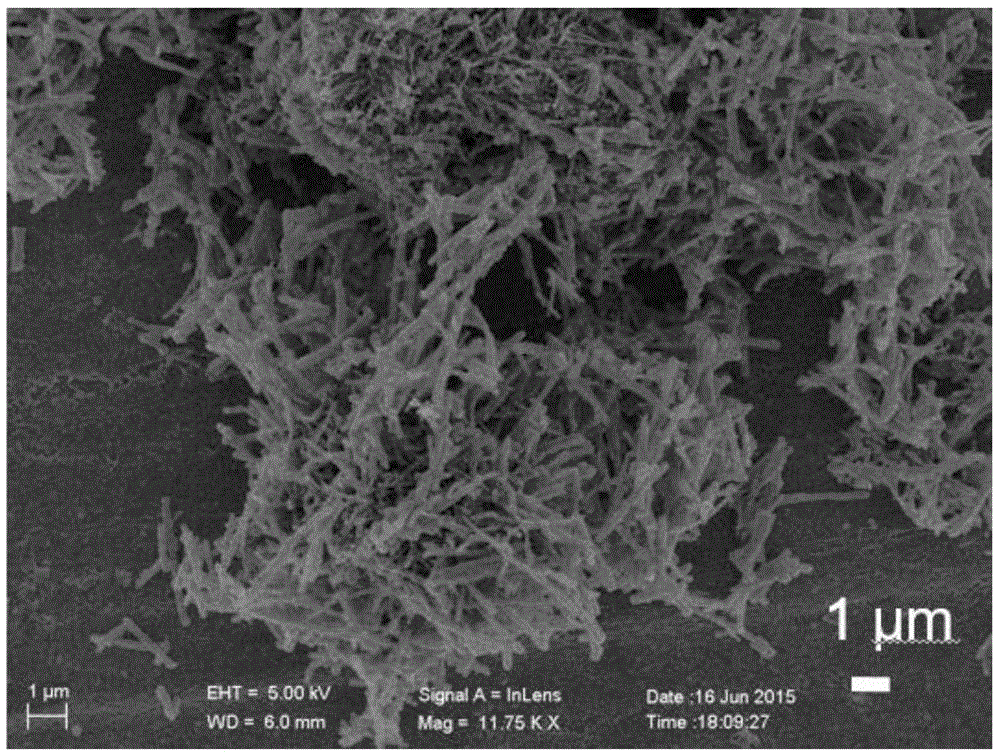

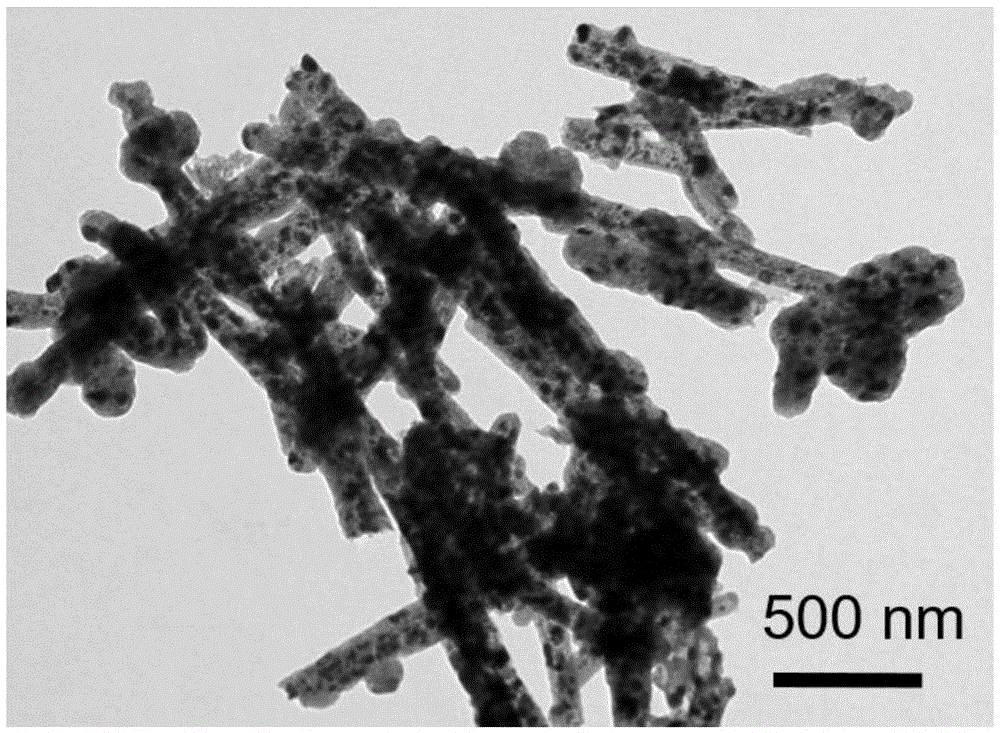

[0075] The composite material that obtains is carried out electron microscope analysis, the result sees Figure 4 . Figure 4 It is the transmission electron micrograph of embodiment 2 gained porous carbon loaded nickel and molybdenum carbide composite material, from Figure 4 It can be seen that, with the transmission electron micrograph of the composite material prepared in embodiment 1 (see figure 2 ) in comparison, its dopamine concentration is lower, and the diameter of nanorods is smaller, ranging from 50 to 75 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com