Thermal spraying aluminum oxide-yttrium oxide composite ceramic coating and preparing method thereof

A technology of yttrium oxide and composite ceramics, which is applied in the field of wear-resistant ceramic coatings, can solve the problems of reduced high-temperature creep resistance of coatings, decreased hardness and strength of coatings, and many grain boundaries of coatings, etc., to achieve strength and toughness. Improved thermal shock resistance, improved wear resistance and effective life, and better interface bonding between coating layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Thermal spraying aluminum oxide-yttrium oxide composite ceramic coating and preparation method thereof, the method comprises the following steps:

[0044] (1) Pretreatment of the metal substrate, including: roughening and purification of the pre-sprayed surface of the metal substrate. Two kinds of 2Cr13 stainless steel substrates: ①Square piece (30mm×15mm×1.25mm); ②Circular ring (Φ40mm×Φ16mm×10mm) is first sandblasted with 20# white corundum sand, and the working pressure is 0.4 ~0.5MPa, then ultrasonic cleaning with ethanol for 5 minutes, and then dry it with compressed air. The average surface roughness Ra of the stainless steel substrate after pretreatment is 7.32 μm;

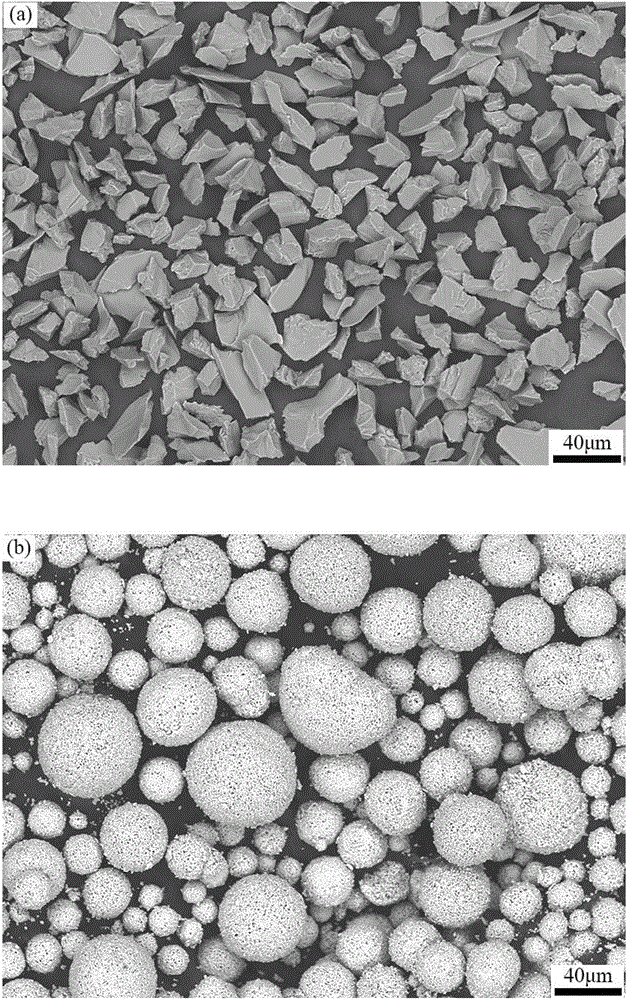

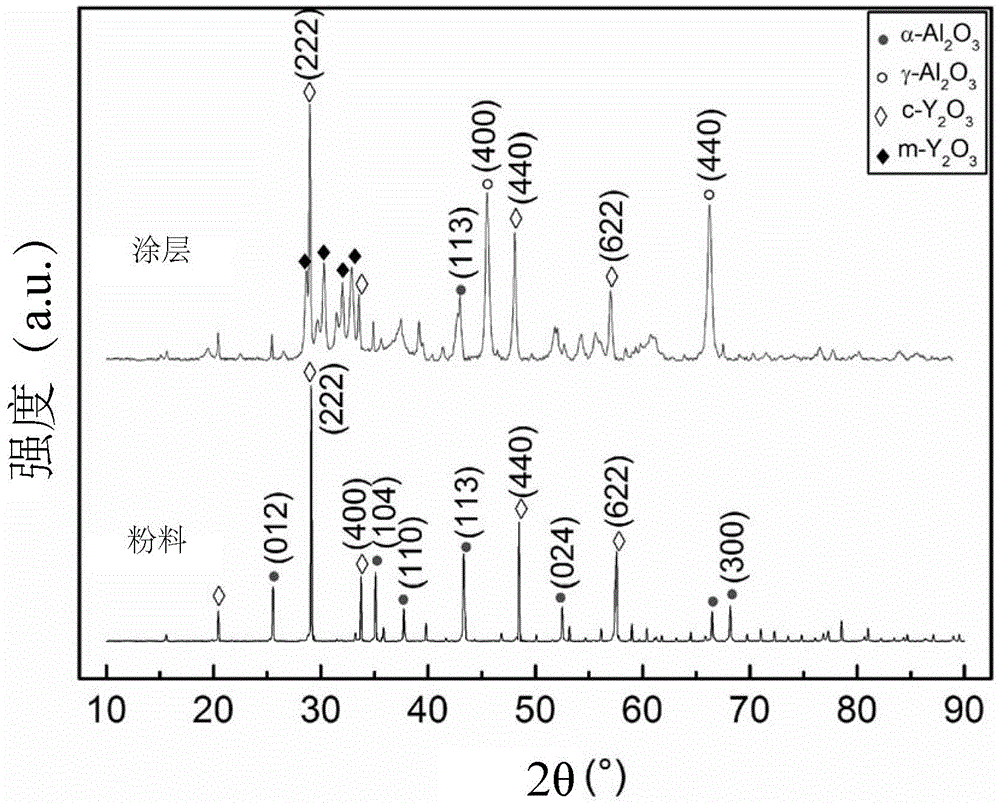

[0045] (2) Aluminum oxide-yttrium oxide composite ceramic coating is deposited on the surface of the treated metal substrate by thermal spraying process. First, the aluminum oxide powder with a particle size of 15-45 μm and the yttrium oxide powder with a particle size of 15-45 μm were mechanically ...

Embodiment 2

[0049] Thermal spraying aluminum oxide-yttrium oxide composite ceramic coating and preparation method thereof, the method comprises the following steps:

[0050] (1) Pretreatment of the metal substrate, including: roughening and purification of the pre-sprayed surface of the metal substrate

[0051] The metal substrate selection and pretreatment method are the same as in Example 1. After pretreatment, the average surface roughness Ra of the stainless steel substrate was 6.56 μm. The square sample is used for section morphology observation and thermal shock test, and the ring sample is used for friction and wear test;

[0052] (2) Aluminum oxide-yttrium oxide composite ceramic coating is deposited on the surface of the treated metal substrate by thermal spraying process

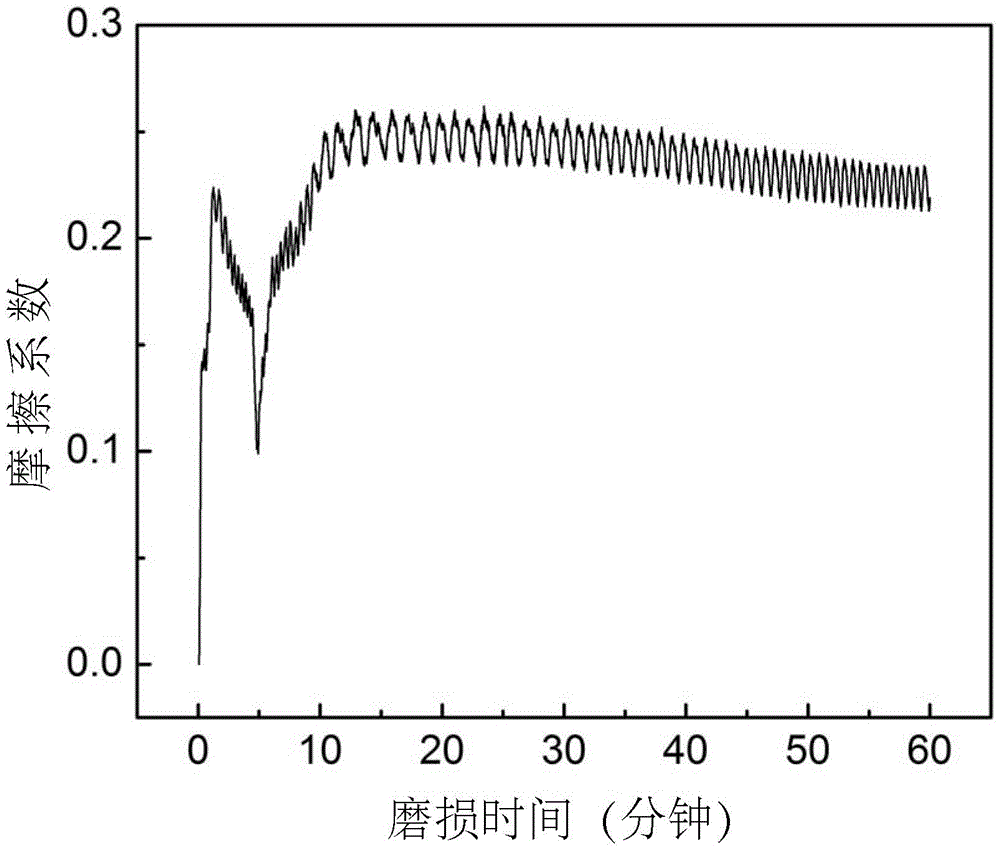

[0053]The preparation method of selecting the composite powder is the same as that of Example 1, except that the mass fraction of yttrium oxide powder is 40%. The nickel-chromium alloy stress transition lay...

Embodiment 3

[0057] Thermal spraying aluminum oxide-yttrium oxide composite ceramic coating and preparation method thereof, the method comprises the following steps:

[0058] (1) Pretreatment of the metal substrate, including: roughening and purification of the pre-sprayed surface of the metal substrate. The metal substrate selection and pretreatment method are the same as in Example 1. The average surface roughness Ra of the stainless steel substrate after pretreatment is 8.19 μm;

[0059] (2) Aluminum oxide-yttrium oxide composite ceramic coating is deposited on the surface of the treated metal substrate by thermal spraying process

[0060] The preparation method of selecting the composite powder is the same as that of Example 1, except that the mass fraction of yttrium oxide powder is 20%. The nickel-aluminum alloy stress transition layer is first sprayed on the surface of the treated 2Cr13 stainless steel substrate. The particle size distribution range of the alloy powder is 35-55 μm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com