Method for preparing fresh edible soybean fermented beverage

A soybean fermentation and beverage technology, applied in dairy products, milk substitutes, applications, etc., can solve the problems of beverages without plant protein, and achieve the effects of preventing intestinal diseases, increasing flavor, and lowering cholesterol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

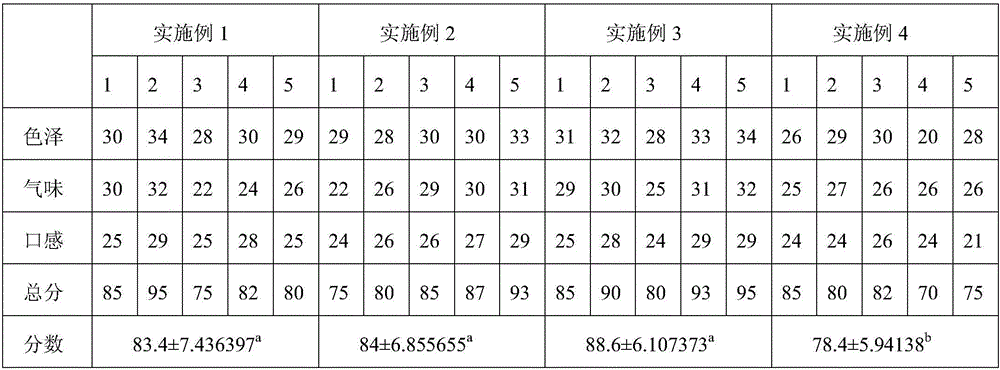

Embodiment 1

[0027] 1.1. Preprocessing

[0028] Select 100 kg of fresh edible soybean kernels with full and complete grains after peeling off the pods, wash and soak in 0.5 wt% sodium bicarbonate solution at room temperature for 12 hours;

[0029] 1.2. Refining

[0030] Inject the pretreated fresh soybean kernels into a refiner, add 500kg of water for grinding, and obtain soybean slurry;

[0031] 1.3. Enzyme hydrolysis

[0032] At 55°C, add α-amylase to the soybean slurry, the amount of α-amylase added per milliliter of soybean slurry is 25U, and enzymolysis for 60min; then add cellulase at 60°C, the cellulose in each milliliter of soybean slurry The amount of enzyme added is 100U, and the enzymolysis is 150min; finally, neutral protease is added, and the amount of neutral protease in each milliliter of soybean slurry is 350U, and the enzymolysis is at 45°C for 30min; filtered through a 200-mesh filter cloth, and the filtrate is retained; the soybean slurry is and enzymatically hydrolyz...

Embodiment 2

[0044] 1.1. Preprocessing

[0045] Wash 300kg of soybeans and soak them in 1wt% sodium bicarbonate solution at room temperature for 12 hours;

[0046] 1.2. Refining

[0047] Inject the pretreated soybeans into a refiner, add 2100kg of water for refining, and obtain soybean slurry;

[0048] 1.3. Enzyme hydrolysis

[0049] At 58°C, add α-amylase to the soybean slurry, the amount of α-amylase added is 50U / mL, and the enzymolysis is 50min; then add cellulase at 60°C, the amount of cellulase added is 150U / mL , enzymatic hydrolysis for 160min; finally add neutral protease, the amount of neutral protease added is 400U / mL, enzymatic hydrolysis for 35min at 50°C; filter through 200 mesh filter cloth, and keep the filtrate;

[0050] 1.4. Enzyme elimination and sterilization

[0051] Heat the filtrate to 70°C, add 144kg white granulated sugar, 4.8kg fructo-oligosaccharide and 2.4kg xylo-oligosaccharide, then heat the filtrate to 85°C to kill enzyme and sterilize for 12 minutes;

[0...

Embodiment 3

[0061] 1.1. Pretreatment of fresh soybeans

[0062] Select 200 kg of fresh edible soybean kernels with full and complete grains after peeling off the pods, wash and soak in 0.5 wt% sodium bicarbonate solution at room temperature for 12 hours;

[0063] 1.2. Refining

[0064] Inject the soaked fresh soybean kernels into a refiner, add 1200kg of water for grinding, and obtain a soybean slurry;

[0065] 1.3. Enzyme hydrolysis

[0066]At 60°C, add α-amylase to soybean slurry, the amount of α-amylase added is 65U / mL, enzymatic hydrolysis for 40min, then add cellulase at 60°C, the amount of cellulase added is 180U / mL , enzymatically hydrolyze for 180min, finally add neutral protease, the amount of neutral protease added is 450U / mL, enzymatically hydrolyze for 35min at 55°C, filter through 200 mesh filter cloth, and keep the filtrate;

[0067] 1.4. Enzyme elimination and sterilization

[0068] Heat the filtrate to 70°C, add 98kg white granulated sugar, 4.2kg fructo-oligosaccharide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com