Coated-type doping method for graphene

A technology of ene coating and graphene, which is applied in chemical instruments and methods, coatings, electronic equipment, etc., can solve the problems of easy migration and volatilization, increase of graphene square resistance, and limit the practical application of graphene, so as to improve the doping The effect of improving the stability of doping and improving the uniformity of doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

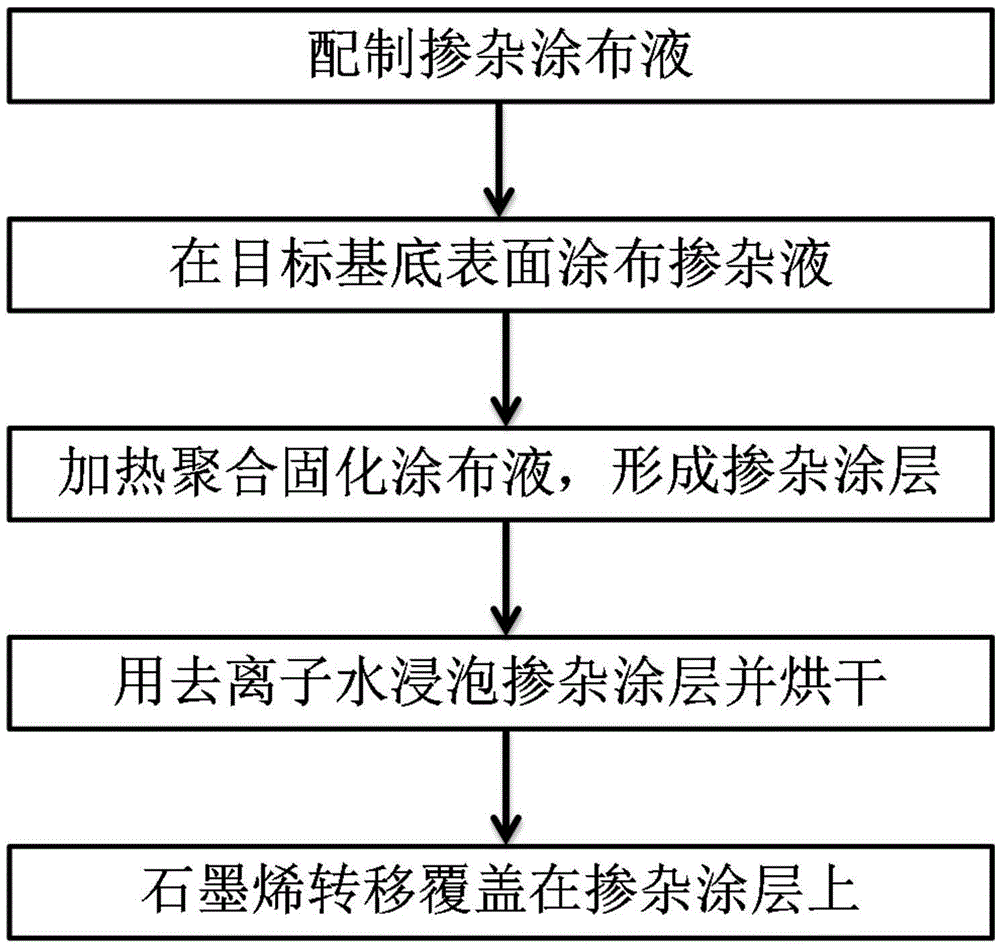

[0022] The steps of this embodiment are as follows:

[0023] Step 1, weigh 9.5gFeCl 3 ·6H 2 O was dissolved in 60g of absolute ethanol and 0.2g of ethylene glycol, then 1.4g of pyridine was added, after stirring evenly, 5g of 3,4-ethylenedioxythiophene monomer was added, and after mixing evenly, it was made into a doping coating solution;

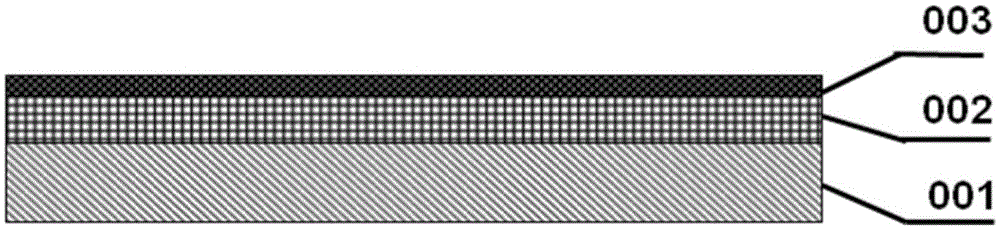

[0024] Step 2, apply the doped coating solution on the target substrate 001 by roller coating method, with a wet film thickness of 20 μm;

[0025] Step 3, heating the coating at 70°C for 50 minutes;

[0026] Step 4, immerse the heat-treated coating in deionized water for 1 min, take it out and dry it to obtain the first doped coating 002;

[0027] Step five, transferring graphene 003 on the first doped coating 002 .

[0028] In this embodiment, the average square resistance of the prepared graphene is 232±15 ohm, heated at 140° C. for 90 minutes, and the average square resistance is 235±13 ohm after 30 days at room temperature, and the ...

Embodiment 2

[0030] The steps of this embodiment are as follows:

[0031] Step 1, weigh 25g of ferric p-toluenesulfonate and dissolve it in a mixed solvent composed of 70g of isopropanol, 65g of n-butanol and 15g of ethylene glycol monoethyl ether, then add 1.6g of pyridine, stir evenly, add 5g of pyrrole monomer, and mix well Afterwards, it is formulated into a doping coating solution;

[0032] Step 2, apply the doped coating solution on the target substrate 001 by slit coating, with a wet film thickness of 15 μm;

[0033] Step 3, heat treatment at 50°C for 120 minutes;

[0034] Step 4, heat treatment, immerse the dried coating in deionized water for 5 minutes, take it out and dry to obtain the first doped coating 002;

[0035] Step five, transferring graphene 003 on the first doped coating 002 .

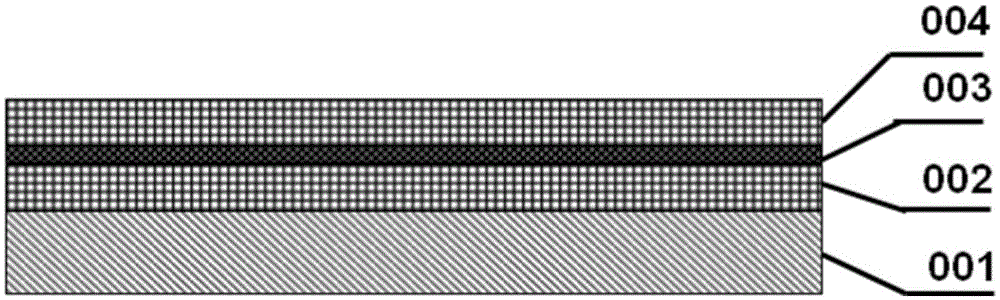

[0036] Repeat steps 1 to 4 to form a second doped coating 004 on the graphene surface.

[0037] In this example, the average square resistance of the prepared graphene is 172±11 ohm, heated...

Embodiment 3

[0039] The steps of this embodiment are as follows:

[0040] Step 1, weigh 30g ferric p-toluenesulfonate and dissolve it in a mixed solvent composed of 30g methanol, 100g n-butanol, 5g ethylene glycol monomethyl ether and 3g ethylene glycol monobutyl ether, then add 0.6g of pyridine and stir evenly Add 5g of monomeric aniline, mix well and make doping coating solution;

[0041] Step 2, apply the doped coating solution on the target substrate 001 by spraying method, with a wet film thickness of 25 μm;

[0042] Step 3, heat treatment at 100°C for 30 minutes;

[0043] Step 4, after heat treatment, immerse the dried coating in deionized water for 3 minutes, take it out and dry to obtain the first doped coating 002;

[0044] Step five, transferring graphene 003 on the first doped coating 002 .

[0045] In this embodiment, the average square resistance of the prepared graphene is 277±16 ohm, heated at 140° C. for 90 minutes, and the average square resistance is 281±15 ohm after 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com