Preparation method of beta-cyclodextrin/polyglutamic acid modified biochar and application of biochar

A technology of polyglutamic acid and cyclodextrin, which is applied in chemical instruments and methods, water pollutants, and other chemical processes, can solve the problems of limited chromium adsorption capacity and limited application of biochar, and achieve rapid preparation and product recovery The effect of high rate and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

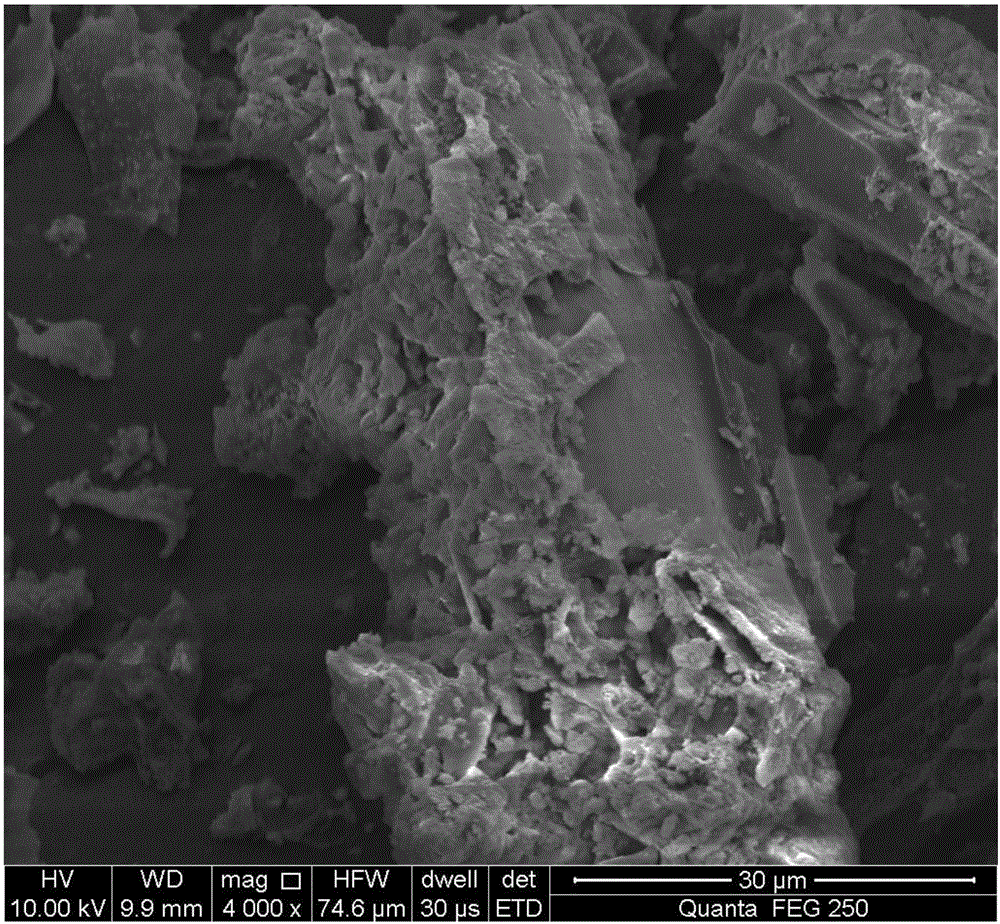

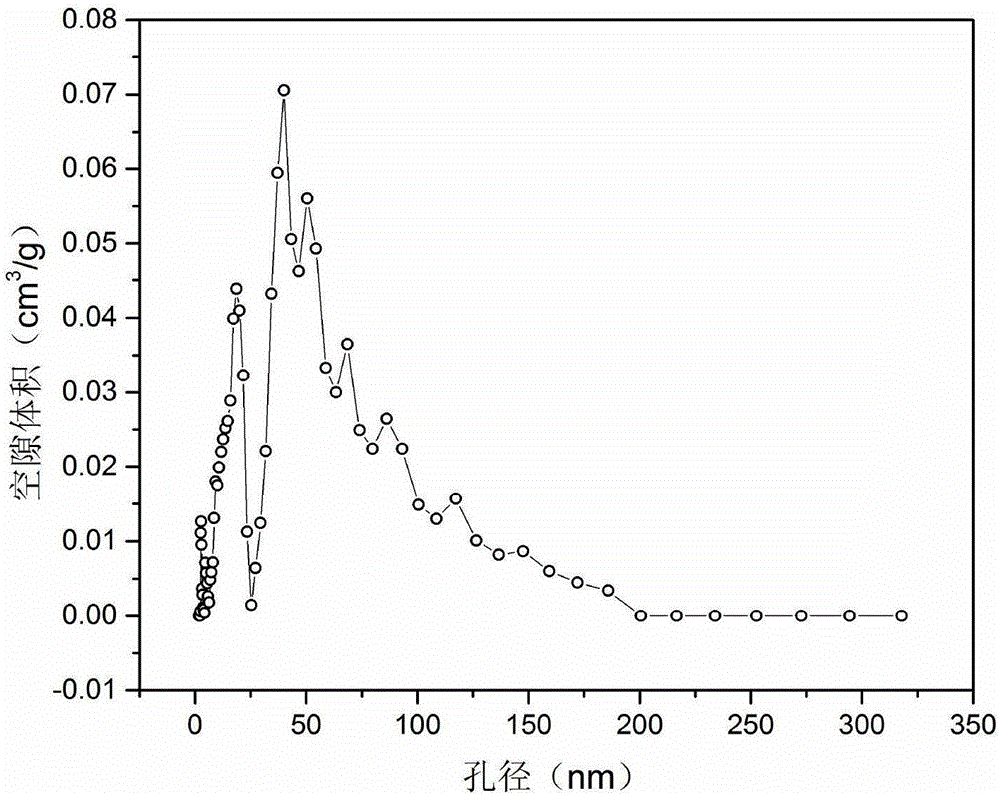

[0026] A kind of preparation of β-cyclodextrin / polyglutamic acid modified biochar of the present invention, biochar raw material selects the ramie stalk of removing leaf and bark for use, and concrete preparation method is as follows:

[0027] Preparation steps of β-cyclodextrin / polyglutamic acid: 10 g of β-cyclodextrin was dissolved in 150 mL of ultrapure water and 40 mL of sodium hydroxide solution. After that, p-toluenesulfonyl chloride (2.6 g) dissolved in 10 mL of acetonitrile was slowly added. Stirring was continued for 3 h at 25 °C and the filtrate was adjusted to neutral after filtration. The filtrate was then placed in a 4°C refrigerator overnight. The filtrate collected white crystals by filtration, and washed 3 times with acetone. Recrystallize in hot water at 90°C, at least 3 times. Dry at 60° C. for 2 days to obtain pure p-toluenesulfonyl β-cyclodextrin crystals. Then take the above 5 g of pure p-toluenesulfonyl β-cyclodextrin crystals and dissolve them in 30 ...

Embodiment 2

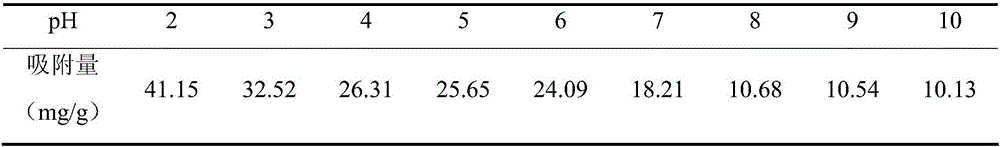

[0031] The β-cyclodextrin / polyglutamic acid modified biochar prepared in Example 1 is applied to the treatment of hexavalent chromium ion wastewater, including the following steps: configure 9 parts of 50mL 100mg / L chromium solution, use 1mol / L of NaOH and HCl adjusted the pH to 2, 3, 4, 5, 6, 7, 8, 9 and 10, respectively. Add the above-mentioned biochar, and the amount of adsorbent is 10 mg. They were placed in constant temperature shaking at 25°C. The rotating speed of the constant temperature oscillator in the water bath is 160rpm, and the shaking time is 24h. After the reaction is over, put it on filter paper for filtration or static precipitation to get the upper layer solution, separate the adsorbent from the solution, and the adsorption process ends. The content of unadsorbed hexavalent chromium in the wastewater was determined by ultraviolet spectrophotometry, and the calculated adsorption results are shown in Table 1.

[0032] Table 1: Adsorption capacity data of ...

Embodiment 3

[0036] The β-cyclodextrin / polyglutamic acid modified biochar prepared in Example 1 is applied to the treatment of hexavalent chromium ion wastewater, comprising the following steps: getting 50mL of the hexavalent chromium solution whose initial concentration is 100mg / L, adjusting The pH value of the solution is 2.0, add 10mg of the biochar, and carry out the adsorption reaction in constant temperature water bath oscillators at 25, 35 and 45°C respectively. solution, the adsorbent is separated from the solution, and the adsorption process is completed, and the content of unadsorbed hexavalent chromium in the wastewater is measured by ultraviolet spectrophotometry. The calculated adsorption results are shown in Table 2.

[0037] Table 2: Adsorption capacity data of adsorbents at different temperatures

[0038]

[0039] It can be seen from Table 2 that the adsorption capacity of the complex to chromium ions is 39.64 mg / g when the reaction temperature is 25 ° C, and increases s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com