Preparation method of nano-structure carbon nitride

A nanostructure, carbon nitride technology, applied in nanotechnology, nitrogen and non-metallic compounds, etc., can solve the problems of difficulty in obtaining, long-term peeling, low yield, etc., achieving low cost, short production cycle, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

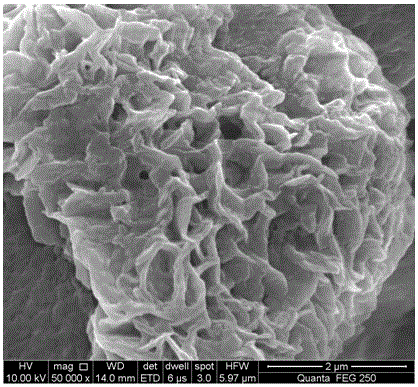

[0039] (1) Grind dicyandiamine, put it into a porcelain boat after passing through a 500-mesh sieve, and place it in a tube furnace, feed nitrogen at a flow rate of 5mL / min, and then raise the temperature to 550°C at a rate of 10°C / min , and kept warm for 2h, cooled to room temperature with the furnace, light yellow solid g-C 3 N 4 ;

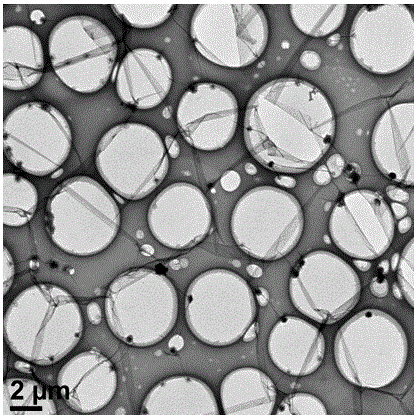

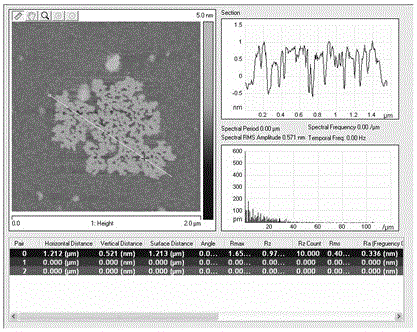

[0040] (2) The light yellow solid g-C obtained in step (1) 3 N 4 Grind, pass through a 500-mesh sieve, and then take 100mg of sieved g-C 3 N 4 Add it into 20mL of potassium hydroxide aqueous solution with a concentration of 3mol / L, heat and condense to reflux at 80°C, stir for 24h, cool to room temperature, then sonicate the sample for 30min, and then use a dialysis bag with a molecular weight of 1500 to dialyze the filtrate for 3d to neutral , to obtain 20mL carbon nitride nano flake aqueous solution;

[0041] (3) Freeze-dry the carbon nitride nanobelt aqueous solution obtained in step (2) at -25°C for 72 hours to constant weight to obtai...

Embodiment 2

[0046] The difference between this embodiment and embodiment 1 is only:

[0047] In step (2), the reflux stirring time is 18h; the final product is carbon nitride nanoflakes, marked as g-C 3 N 4 -water-2. The rest are the same as embodiment 1.

[0048] After testing, the specific surface area of carbon nitride nanosheets obtained in this example is 280m 2 g -1 , and the yield also reached 100wt%. Nanosheets with few layers of thickness can be obtained. The width of the obtained nanosheets is about 0.8-3.3 μm, and the sheets are much larger than those obtained in Example 1, resulting in a solution that is not as clear as in Example 1. g-C 3 N 4 -Water-2 After standing for a month, a very small amount of precipitation occurs at the bottom of the bottle, and the stability is not as good as that of g-C 3 N 4- Water1.

Embodiment 3

[0050] The difference between this embodiment and embodiment 1 is only:

[0051] In step (2), the reflux stirring time is 12h, marked as g-C 3 N 4 -water-3. The rest are the same as embodiment 1. After testing, the specific surface area of carbon nitride nanosheets obtained in this example is 235m 2 g -1 , the width of the obtained nanosheets is about 1.2-3.6 μm, and the yield is 75wt%. The aqueous solution obtained in this embodiment is light milky white, and a small amount of precipitation occurs at the bottom of the bottle after standing for a week.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com