Method for increasing ohmic contact characteristic of silicon carbide semiconductor

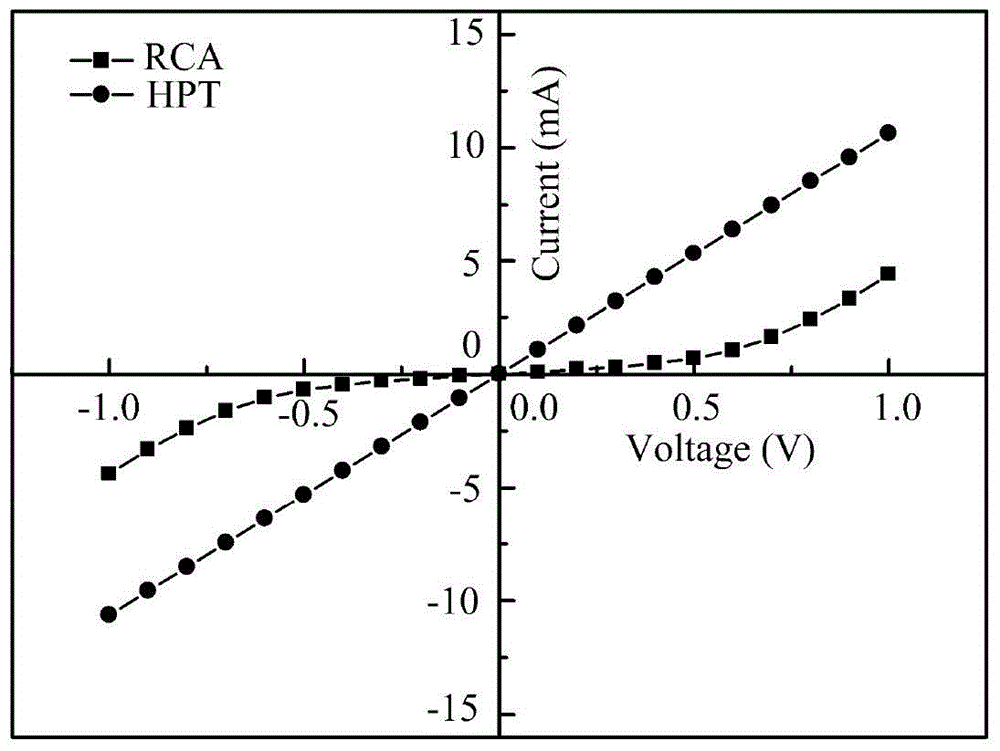

An ohmic contact and silicon carbide technology, applied in the field of microelectronics, can solve the problems of poor thermal stability and process compatibility, high preparation cost, and achieve the effect of reducing surface state density, low barrier height, and improving ohmic contact characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

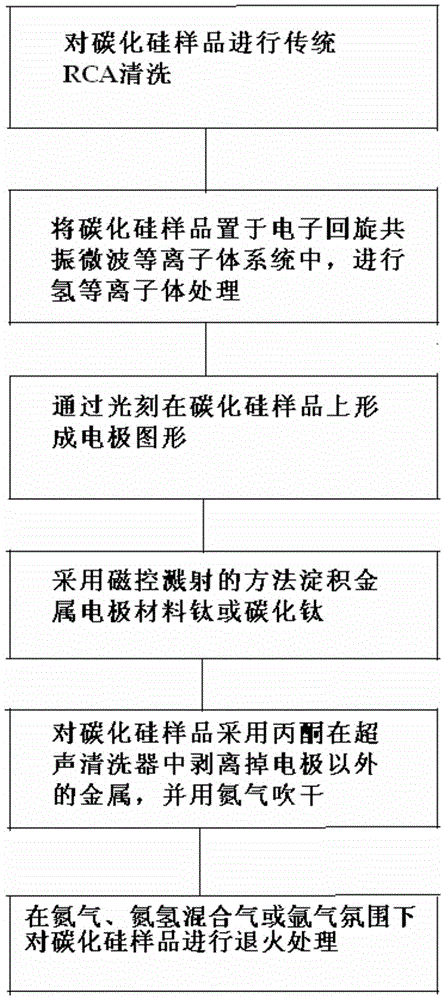

[0029] The present invention will be further described below in conjunction with accompanying drawing.

[0030] Such as figure 1 As shown, a method for improving the ohmic contact characteristics of a silicon carbide semiconductor comprises the following steps:

[0031] Step 1. Carry out traditional RCA cleaning on the silicon carbide sample, which specifically includes the following sub-steps:

[0032] (a) Clean the silicon carbide sample with deionized water and ultrasonic until there is no obvious foreign matter;

[0033] (b) using concentrated sulfuric acid (H 2 SO 4 ) cleaning, the H 2 SO 4 Heat to 80°C, boil for 10 minutes, put in the cleaned silicon carbide sample, soak for 30 minutes, add H 2 o 2 Soak for another 15 minutes, rinse the silicon carbide sample several times with deionized water;

[0034] (c) Use No. 1 standard solution (deionized water, NH 4 OH and H 2 o 2 Mixed solution) cleaning, DIW cleaning several times, buffered hydrofluoric acid cleaning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com