Method for preparing supported precious metal/zinc oxide hybrid nanometer materials

A technology of zinc oxide nano- and hybrid materials, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of easy migration of active metal components, catalysts Problems such as poor metal dispersion and low activity specific surface area can achieve the effect of uniform and stable loading, high catalytic activity and large active surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This example aims to illustrate the feasibility of preparing the supported Pd / ZnO hybrid nanomaterial of the present invention.

[0035] (1) Preparation of reaction precursor: Take 10ml N-N dimethylformamide with a pipette gun and place it in a beaker, then add 2ml distilled water to the beaker, weigh 3mg palladium acetylacetonate (Pd(acac) 2 ) into a beaker, and then weighed 60mg of zinc acetylacetonate (Zn(acac) 2 ) into the beaker, and then weighed 100mg of polyvinylpyrrolidone (PVP) into the beaker, and finally added NaOH solution to adjust its pH value, and placed the beaker on a magnetic stirrer to stir for 30 minutes to fully dissolve the reaction precursor.

[0036] (2) Implementation of hydrothermal reaction: move the mixed solution to the polytetrafluoroethylene reaction kettle lining, put the kettle lining into the reaction kettle and tighten it, set the oven temperature to 140°C, put the reaction kettle in the oven, and keep the temperature constant React f...

Embodiment 2

[0039] This example aims to illustrate the feasibility of preparing the supported Pt / ZnO hybrid nanomaterial of the present invention.

[0040] (1) Preparation of the reaction precursor: Take 10ml of N-N dimethylformamide with a pipette gun and place it in a beaker, then add 2ml of distilled water to the beaker, weigh 3mg of platinum acetylacetonate (Pt(acac) 2 ) into a beaker, and then weighed 60mg of zinc acetylacetonate (Zn(acac)2 ) into the beaker, and then weighed 100mg of polyvinylpyrrolidone (PVP) into the beaker, and finally added NaOH solution to adjust its pH value, and placed the beaker on a magnetic stirrer to stir for 30 minutes to fully dissolve the reaction precursor.

[0041] (2) Implementation of hydrothermal reaction: move the mixed solution to the polytetrafluoroethylene reaction kettle lining, put the kettle lining into the reaction kettle and tighten it, set the oven temperature to 140°C, put the reaction kettle in the oven, and keep the temperature constan...

Embodiment 3

[0044] This example aims to characterize the supported Pd / ZnO and Pt / ZnO hybrid nanomaterials in the present invention.

[0045] Comprehensive physical properties: Take the supported Pd / ZnO and Pt / ZnO nano-hybrid materials prepared in Example 1 and Example 2, and analyze the overall performance of the composite nano-materials by scanning electron microscope, transmission electron microscope and X-ray diffractometer. Morphology, Pd or Pt loading, crystal form, etc. were characterized.

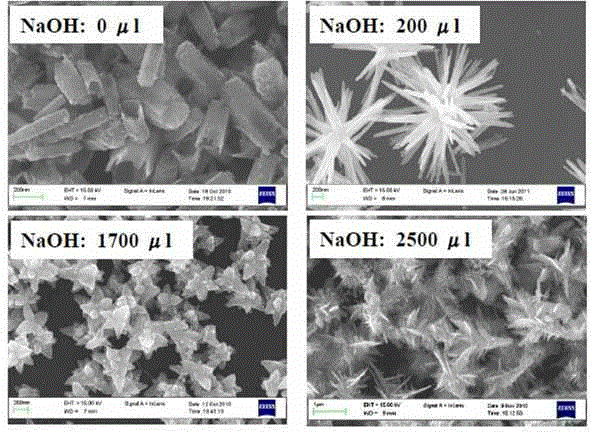

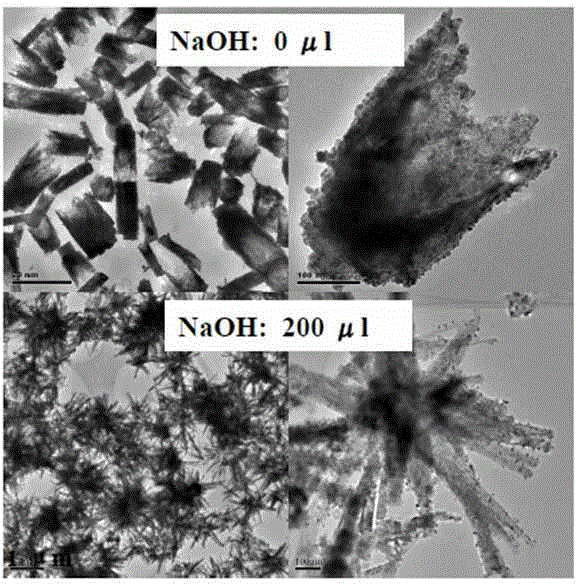

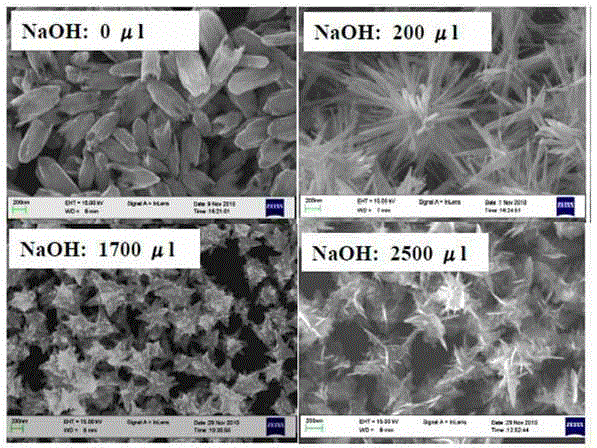

[0046] By changing the amount of NaOH solution in the reaction (NaOH solution is 0 μL, 200 μL, 1700 μL and 2500 μL), the morphology of the carrier ZnO can be continuously adjusted in nanotube shape, dandelion flower shape, stacked star shape, and burr lamination (such as figure 1 and 3 shown). According to transmission electron microscopy results (such as figure 2 and 4 As shown), it can be seen that the loading capacity of Pd or Pt is relatively large, and the particles are evenly disperse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com