Catalyst for catalytic hydrogenation of 3-hydroxyl propionaldehyde to prepare 1,3-propylene glycol, preparation method and applications thereof

A technology of hydroxypropionaldehyde and catalyst, which is applied in the catalytic hydrogenation of 3-hydroxypropionaldehyde to prepare 1, which can solve the problems of high reaction conditions, difficulty in large-scale industrial application, difficulty in separating catalyst and reaction liquid, etc., and reduce the reaction pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

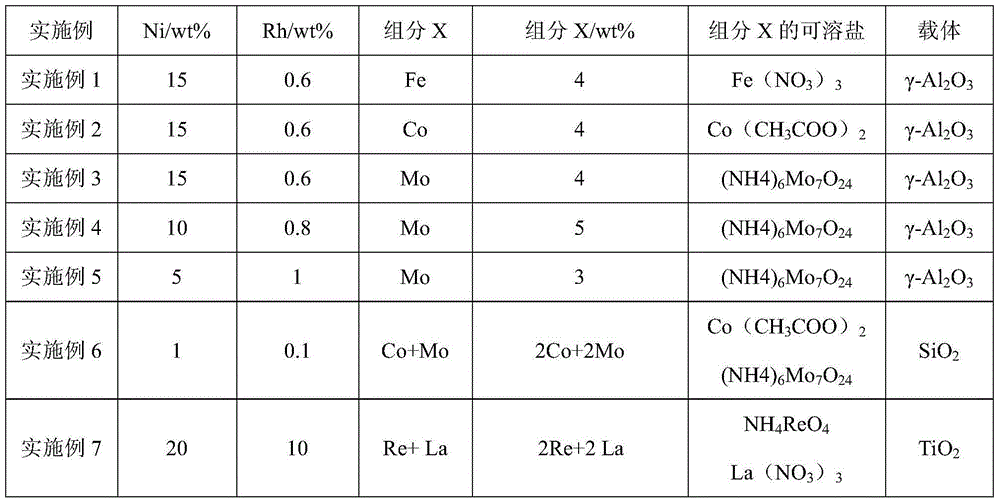

Examples

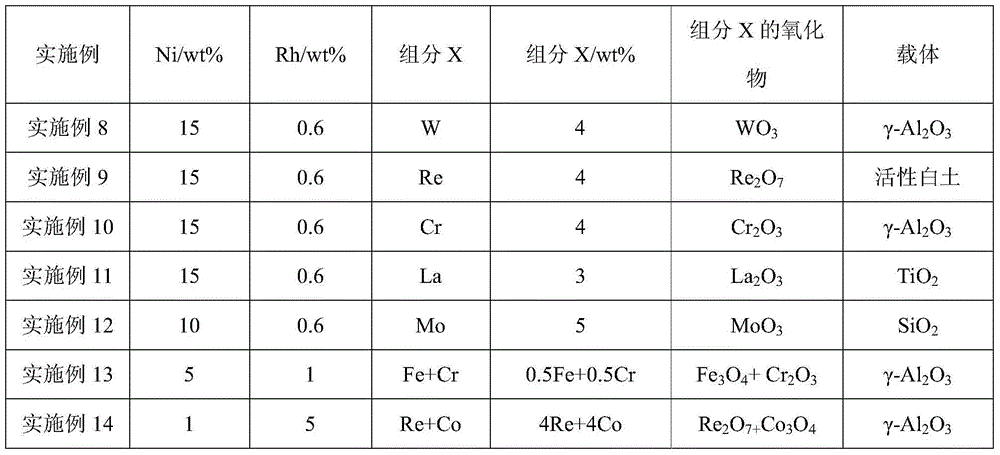

Embodiment 8-14

[0071] Embodiment 8-14 adopts mixing method to prepare 3-hydroxy propionaldehyde hydrogenation to prepare 1,3-propanediol catalyst:

[0072] (1) Take by weighing the oxide compound of nickel oxide, rhodium oxide, auxiliary agent X and carrier by metering ratio, join in the kneader, fully mix;

[0073] (2) adding concentration is 15wt% dilute nitric acid as binder, consumption is 5wt% of dry powder, adds polyethylene glycol (polymerization degree 3000) as structural aid, consumption is 4wt% of dry powder;

[0074] (3) The kneading rate is 20rpm, kneading 4h;

[0075] (4) Knead and mix evenly and extrude into strips, and the shearing is 5mm;

[0076] (5) Then dry at 100°C for 4h, and bake at 450°C for 6h.

[0077] Reduction pretreatment: put into the reactor after roasting, under the pressure of 0.2MPa, H 2 :N 2 = 1:2 mixed gas, the temperature is 360 ° C for 36 hours, after the reduction is completed, adjust to the conditions required for the reaction.

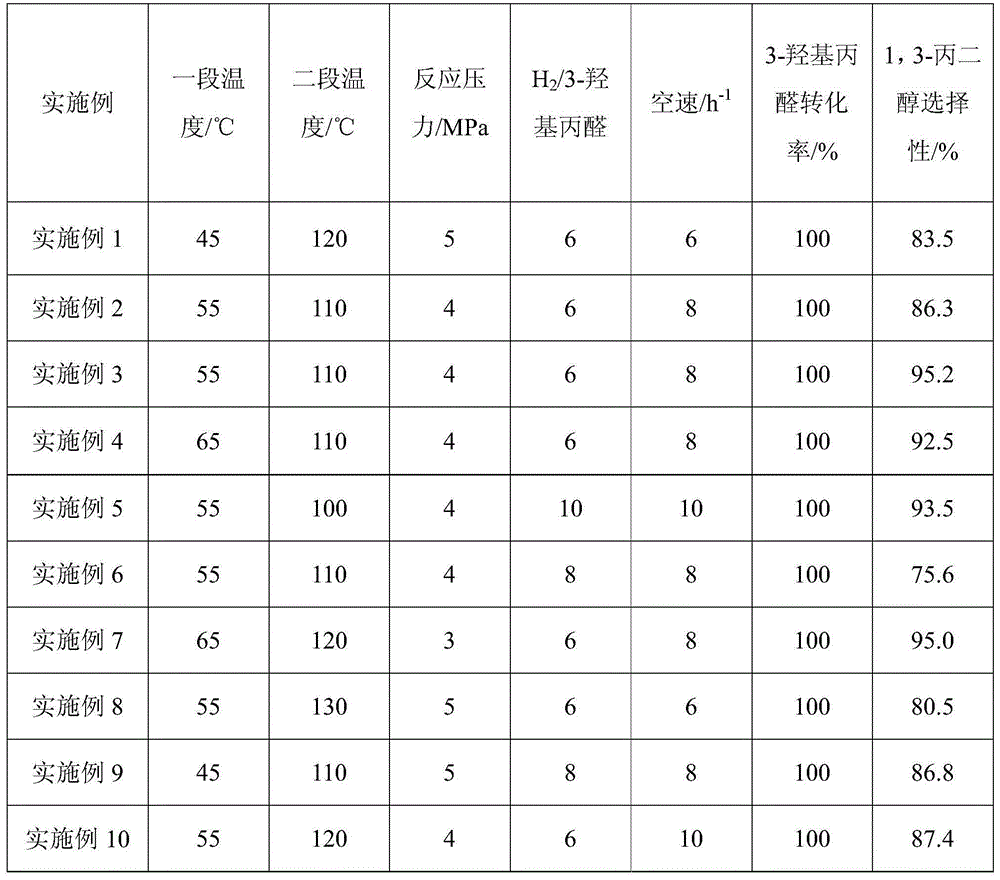

[0078] The catalys...

Embodiment 15

[0091] The hydrogenation catalyst in the prepared embodiment 3 is loaded into two-stage reactors connected in series, the two-stage reactors are filled with a mass ratio of 3:1, and the second stage is based on the Ni-Rh-X / A loaded multi-component The mass ratio of the catalyst is 1:8 and the sulfonic acid type cation exchange resin is added. Reduction at 360°C for 36h, and cooling down to 55°C after reduction. The 3-hydroxy propionaldehyde aqueous solution and H of raw material concentration 8wt% 2 After preheating, it enters the reactor. Reaction conditions: the first stage reaction temperature is 55°C, the second stage reaction temperature is 110°C, and the hourly space velocity of 3-hydroxypropanal aqueous solution is 8h -1 , H 2 : The molar ratio of 3-hydroxypropanal is 6:1, the reaction pressure is 4MPa, after 300h of reaction, the conversion rate of 3-hydroxypropanal is 99.9%, and the selectivity of 1,3-PDO is 95%. This example illustrates that the catalyst of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com