Mechanical-etching composite processing method for continuous surface quartz micro-optical elements

A composite processing and micro-optical technology, applied in optical components, optics, lenses, etc., can solve problems such as low controllability, poor uniformity of lithography technology, and limited materials for ultra-precision processing technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

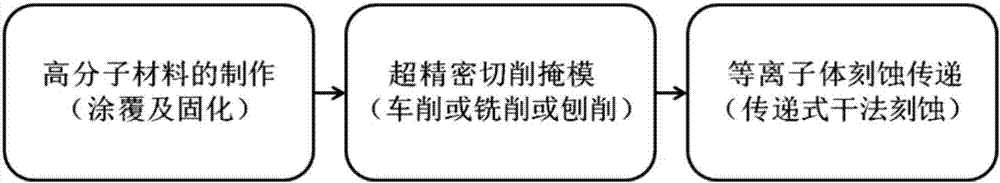

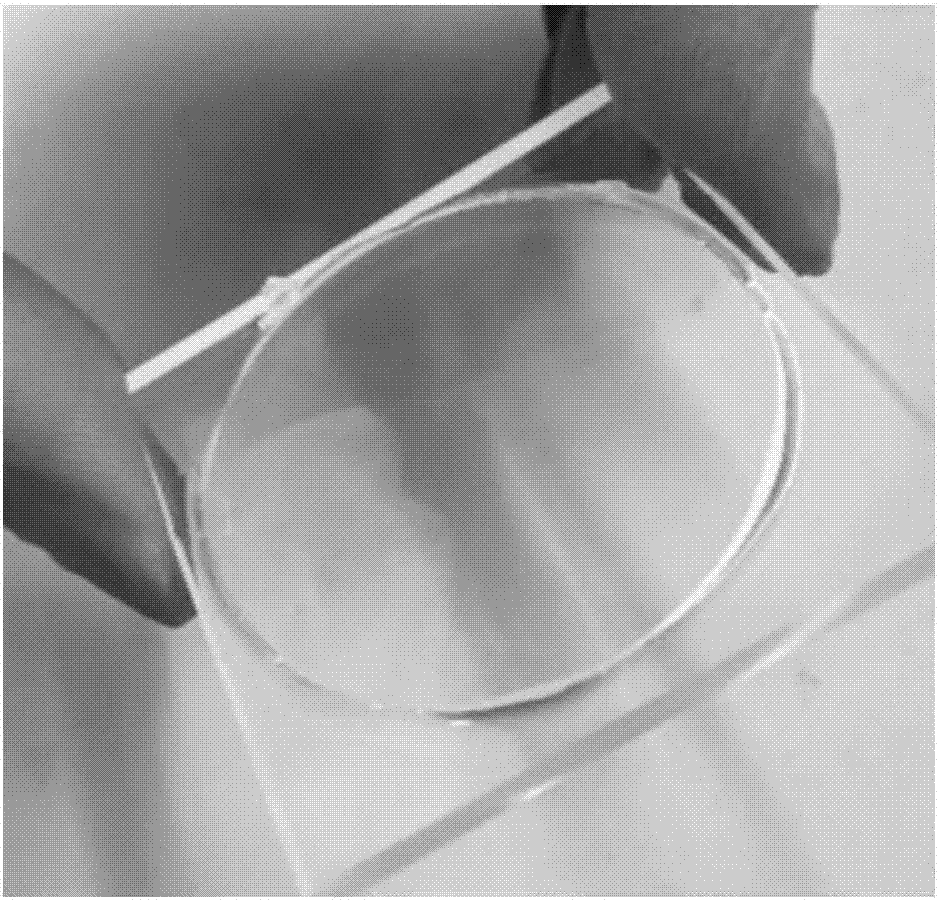

[0032] This embodiment provides a continuous surface-shaped quartz micro-optical element mechanical-etching composite processing method, specifically a continuous surface-shaped quartz Fresnel lens manufacturing method, the implementation steps are as follows figure 1 As shown, the details are as follows: (1) The photosensitive adhesive NOA61 is coated on the quartz substrate by spin coating, and the photosensitive adhesive is cured under the irradiation of 365nm light emitted by the ultraviolet exposure machine, and the irradiation meter is about 100mJ / cm 2 , in order to improve the cutting performance of the photosensitive adhesive, it was baked in a 60-degree oven for 30 minutes, and the obtained quartz-coated photosensitive adhesive sample was as follows: figure 2 shown. (2) Photosensitive adhesive continuous surface Fresnel lens mask turning processing, Fresnel lens depth 8um, minimum ring width 100um, area diameter 50mm. Using a diamond tool with a radius of 0.02mm, th...

Embodiment 2

[0036] This embodiment provides a mechanical-etching composite processing method for a continuous surface-shaped quartz micro-optical element, specifically a method for manufacturing a continuous surface-shaped microlens array, and the implementation steps are as follows:

[0037] (1) Coat PMMA with a leveling method on the quartz substrate, and bake in a 70-degree oven for 30 minutes to fully solidify the PMMA;

[0038](2) PMMA continuous surface-shaped microlens array mask turning process, the side length of the microlens array is 3um, the depth is 600nm, and the area diameter is 20mm. Turning is used to smooth PMMA, the spindle speed is 3000rpm, the feed rate of the Z axis is 20um, the feed rate of the X direction is 10mm / min, the feed rate of the finish car is 5um, and the feed rate of the X axis is 2mm / min. Prepare the processing program, use the diamond sharp knife, use the milling axis to process, the milling axis speed is 30000rpm, the feed rate of the Z axis is 1um, t...

Embodiment 3

[0042] This embodiment provides a mechanical-etching composite processing method for continuous surface-shaped quartz micro-optical elements, specifically a method for manufacturing a quartz columnar lens array, and the implementation steps are as follows:

[0043] (1) Apply photoresist AZ9260 by spin coating on the quartz substrate, 1000rpm, 30s; bake on a 100 degree hot plate for 10min, so that the photoresist is fully cured;

[0044] (2) Photoresist continuous surface cylindrical lens array mask turning processing, the cylindrical lens array has a side length of 500um, a depth of 11um, and an area diameter of 20mm. Turning is used to smooth PMMA, the spindle speed is 3000rpm, the feed rate of the Z axis is 20um, the feed rate of the X direction is 10mm / min, the feed rate of the finish car is 5um, and the feed rate of the X axis is 2mm / min. Prepare the processing program, adopt the Y-axis planing processing technology, the Y-axis movement speed is 600mm / min, the Z-axis rough...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com