A kind of amorphous manganese oxide coated iron oxide lithium/sodium ion battery negative electrode material and preparation method thereof

A sodium ion battery, manganese oxide technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as the harm of lithium / sodium ion batteries, achieve good electrochemical performance, improve kinetic performance, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

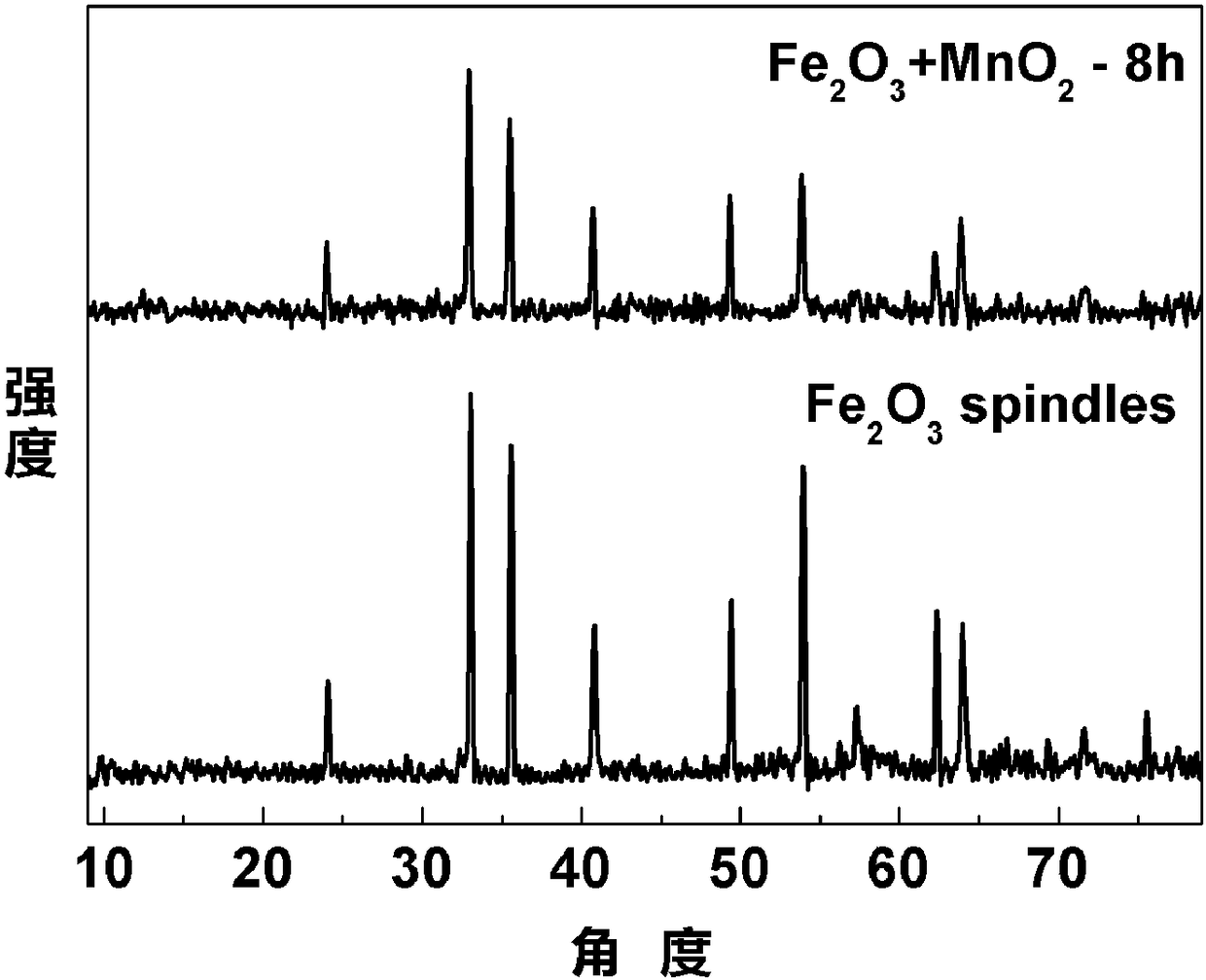

[0026] Solution A: Weigh 80mg Fe 2 o 3 , dispersed it in 25mL deionized water, and obtained a uniform dispersion after ultrasonication for 30 minutes. Solution B: 0.20g KMnO 4 Dissolve in 25mL deionized water, then add 0.8mL 1M HCl, stir well. After solution B was heated to 95°C, solution A was added dropwise thereto. Under magnetic stirring, the mixture was heated at 95 °C for 2 h. After natural cooling, the product was washed several times by centrifugation with deionized water and ethanol, and then dried at 80°C to obtain brown amorphous MnO 2 Coated Fe 2 o 3 composite material.

[0027] In the above preparation method, heating the mixed solution at 95°C for 2h to extend to 5h, 8h, 14h or 23h can also obtain brown amorphous MnO 2 Coated Fe 2 o 3 composite material.

[0028] In N-methyl-pyrrolidone (NMP) as solvent, the amorphous MnO 2 Coated Fe 2 o 3 The composite material is mixed evenly with acetylene black and polyvinylidene fluoride (PVDF) according to the...

Embodiment 2

[0034] Solution A: Weigh 400mg Fe 2 o 3 , dispersed it in 25mL deionized water, and obtained a uniform dispersion after ultrasonication for 30 minutes. Solution B: 1.20g KMnO 4 Dissolve in 25mL deionized water, then add 10.0mL 1M HCl, stir well. After solution B was heated to 140°C, solution A was added dropwise thereto. Under magnetic stirring, the mixture was heated at 140 °C for 8 h. After natural cooling, the product was washed several times by centrifugation with deionized water and ethanol, and then dried at 80°C to obtain brown amorphous MnO 2 Coated Fe 2 o 3 composite material. in H 2 (30%H 2 and 70% Ar) atmosphere, the prepared MnO 2 Coated Fe 3 o 4 The composite was fired at 350°C for 5h. After cooling to room temperature, the product was centrifuged and then dried to obtain amorphous MnO 2 Coated Fe 3 o 4 composite material.

[0035] In N-methyl-pyrrolidone (NMP) as solvent, the amorphous MnO 2 Coated Fe 3 o 4 The composite material is mixed even...

Embodiment 3

[0037] in H 2 (30%H 2 and 70% Ar) atmosphere, the Fe 2 o 3 Burn at 350°C for 5h. After being cooled to room temperature, the product was subjected to centrifugal washing and drying to obtain Fe 3 o 4 . Solution A: Weigh 40mg Fe 3 o 4 , dispersed it in 25mL deionized water, and obtained a uniform dispersion after ultrasonication for 30 minutes. Solution B: 0.40g KMnO 4 Dissolve in 25mL deionized water, then add 0.5mL 2M HCl, stir well. After solution B was heated to 95°C, solution A was added dropwise thereto. Under magnetic stirring, the mixture was heated at 95 °C for 8 h. After natural cooling, the product was washed several times by centrifugation with deionized water and ethanol, and then dried at 80°C to obtain brown amorphous MnO 2 Coated Fe 3 o 4 composite material.

[0038] In N-methyl-pyrrolidone (NMP) as solvent, MnO 2 Coated Fe 3 o 4 The composite material is mixed evenly with acetylene black and polyvinylidene fluoride (PVDF) according to the mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com