Stannic oxide/graphene/carbon composite material and preparation method thereof

A technology of carbon composite materials and tin dioxide, applied in the direction of secondary batteries, electrochemical generators, electrical components, etc., can solve the problems affecting the structural stability and electrochemical performance of materials, so as to improve the cycle stability and strengthen the combination Function, the effect of maintaining structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

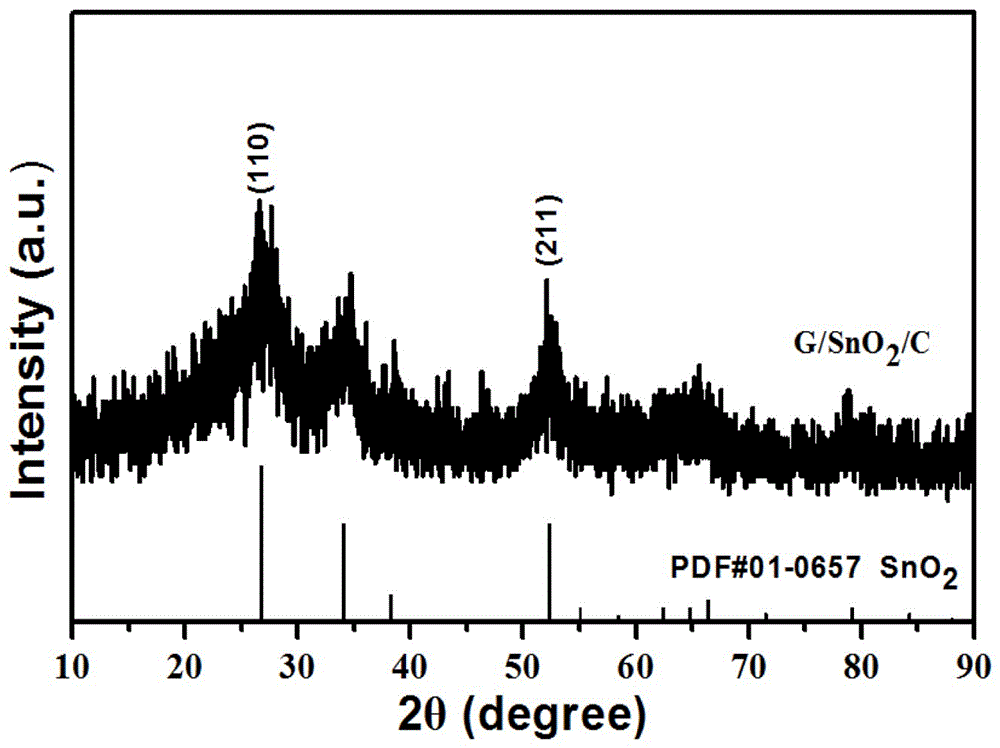

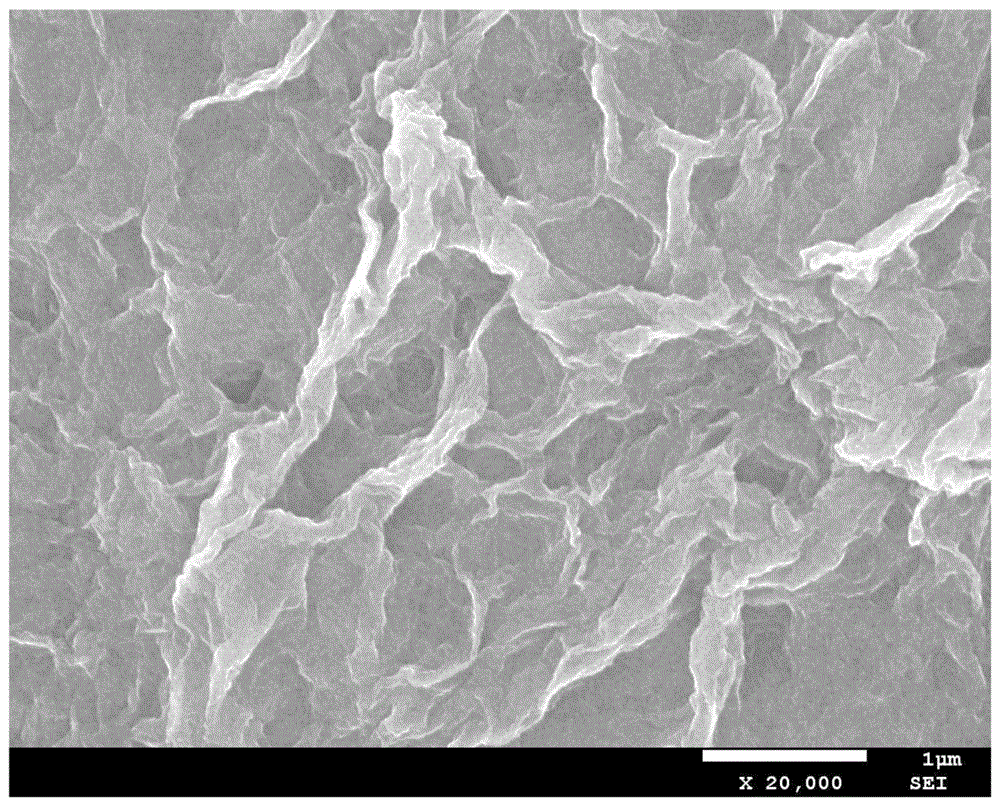

[0023] Example 1: Three-dimensional tin dioxide / graphene / carbon foam composite electrode material I

[0024] Cool concentrated sulfuric acid to 0°C, then add graphite and sodium nitrate, stir until uniform, gradually and continuously add potassium permanganate, stir for 3 hours, raise the temperature to 35°C, continue stirring for 0.5h, then gradually and continuously add Ionized water, the temperature rises to 98°C, reacts at this temperature for 15 minutes, moves to normal temperature, adds 10% hydrogen peroxide, stirs for 1 hour, then adds 1M hydrochloric acid and mixes and stirs, and the obtained product is washed with deionized water until it is neutral to obtain oxidised graphite. Graphite oxide was dispersed in deionized water at a concentration of 4 mg / mL, and ultrasonically exfoliated to obtain a graphene oxide material. Mix graphene oxide, tin tetrachloride, and glucose in a mass ratio of 1:5:1. After ultrasonic dispersion is uniform, the mixed solution is transferr...

Embodiment 2 3

[0025] Example 2 Three-dimensional tin dioxide / graphene / carbon foam composite electrode material II

[0026] The graphene oxide material was prepared as described in Example 1, graphene oxide, tin tetrachloride, and glucose were mixed in a mass ratio of 1:10:1, and after ultrasonic dispersion was uniform, the mixed solution was transferred to polytetrafluoroethylene In an ethylene-lined autoclave, a hydrothermal reaction was carried out at 220 °C for 32 hours to obtain a tin dioxide / graphene / carbon liquid gel composite material. The prepared tin dioxide / graphene / carbon liquid gel composite was freeze-dried, followed by heat treatment at 750 °C for 2 h to obtain a three-dimensional tin dioxide / graphene / carbon foam composite. The test conditions of the electrode material are as described in Example 1, charge and discharge at a current density of 100mA / g, the first discharge capacity can reach 1800mAh / g, and the capacity after the second cycle is still 550mAh / g.

Embodiment 3 3

[0027] Example 3 Three-dimensional tin dioxide / graphene / carbon foam composite electrode material III

[0028] The graphene oxide material was prepared as described in Example 1, graphene oxide, tin tetrachloride, and glucose were mixed in a mass ratio of 1:20:1, and after ultrasonic dispersion was uniform, the mixed solution was transferred to polytetrafluoroethylene In an ethylene-lined autoclave,

[0029]Hydrothermal reaction at 240°C for 48 hours to obtain a tin dioxide / graphene / carbon liquid gel composite material. The prepared tin dioxide / graphene / carbon liquid gel composite was freeze-dried, followed by heat treatment at 1000 °C for 2 h to obtain a three-dimensional tin dioxide / graphene / carbon foam composite. The test conditions of the electrode material are as described in Example 1, charge and discharge at a current density of 100 mA / g, the first discharge capacity can reach 2000 mAh / g, and the capacity after the second cycle is still 630 mAh / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com