Perovskite solar battery and supercapacitor integrated part and preparation method thereof

A technology for supercapacitors and solar cells, which can be used in capacitor collector combinations, electric solid-state devices, semiconductor/solid-state device manufacturing, etc. It can solve problems such as the inability to apply flexible electronic products, and the lack of research on the integration of perovskite solar cells and supercapacitors. , to achieve the effects of optimizing the preparation cost, reducing the preparation cost and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

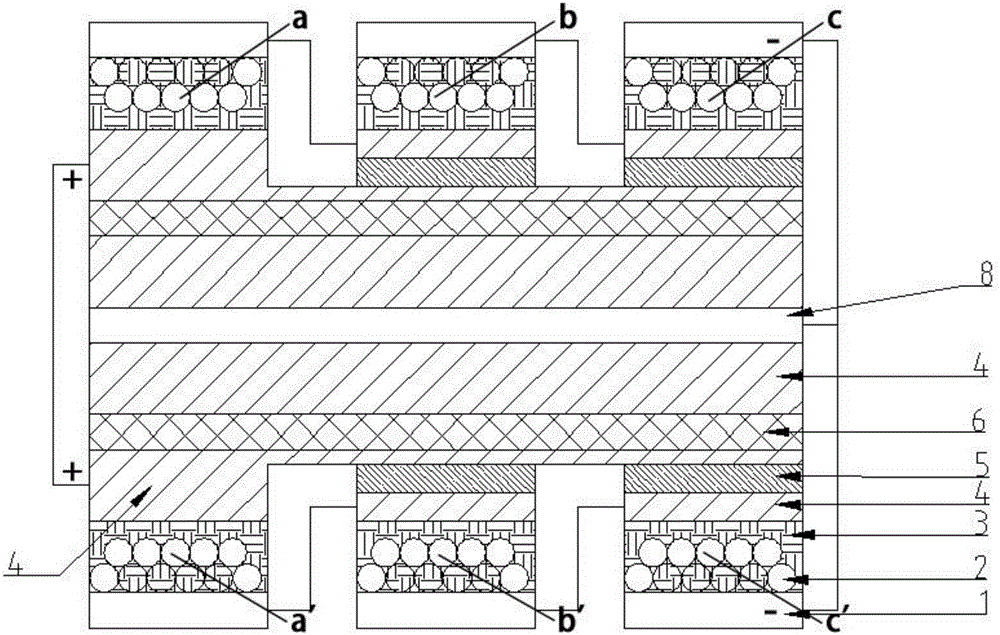

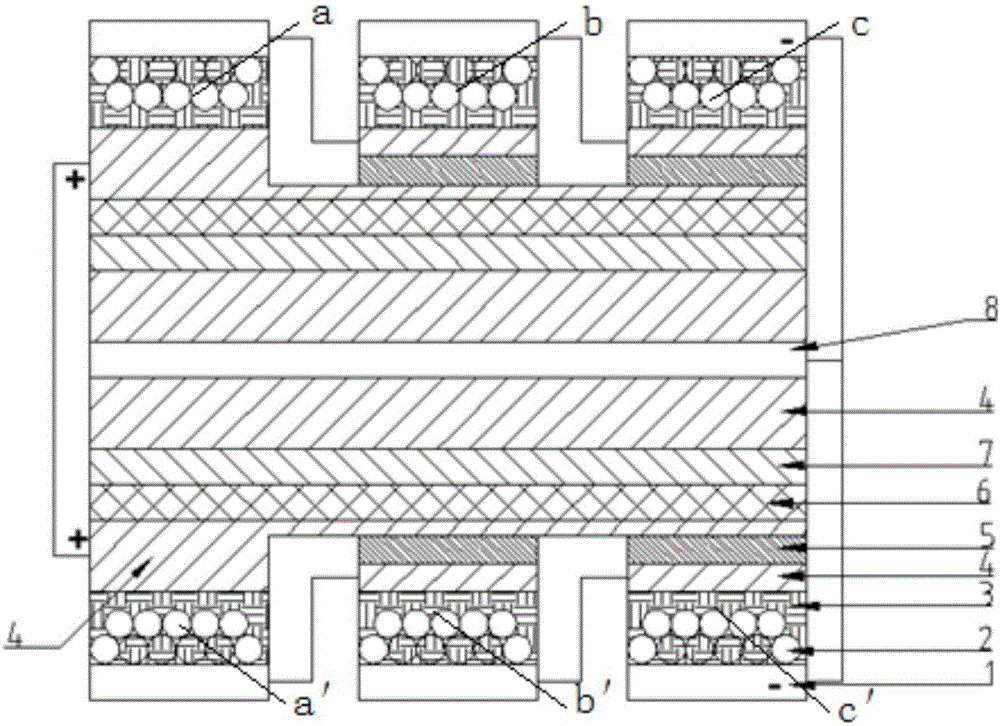

[0048] The embodiment of the present invention also provides a method for preparing a perovskite solar cell and supercapacitor integration, which mainly includes the following steps:

[0049] 1) Preparing and pre-treating the conductive substrate (i.e. the second conductive substrate 1) of the solar cell unit, the conductive substrate is a transparent conductive substrate;

[0050] 2) Preparation of TiO on the pretreated conductive substrate 2 or ZnO or Al 2 o 3 As the solar cell photoanode 2, for example, it is prepared by hydrothermal growth, spin coating, magnetron sputtering, and electron beam evaporation;

[0051] 3) Prepare the perovskite layer 3 on the prepared photoanode by a one-step method or a two-step method;

[0052] 4) Printing a conductive carbon paste on the prepared perovskite layer to prepare a carbon electrode 4, and completing the preparation of a solar cell unit;

[0053] 5) Repeat steps 1)-4) to prepare multiple solar cell units, for example 3, connec...

Embodiment 1

[0064] Step 1: Clean the cut FTO ultrasonically with acetone and ethanol for 15 minutes respectively to remove organic matter on the surface, then wash it with deionized water, and finally put it in a UV-ozone cleaning machine for 30 minutes for surface modification;

[0065] Step 2: Spin-coat TiO on the surface of the pretreated FTO substrate 2 Dispersion (buy Dyesol's TiO 2 The slurry is diluted with ethanol according to a weight ratio of 2:7), and then annealed at 500°C for 30 minutes, and the photoanode is prepared;

[0066] Step 3: Two-step preparation of CH on the photoanode prepared in Step 2 3 NH 3 PB 3 Perovskite film: First, spin-coat 1.2mol / LPbI on the surface of the photoanode 2 Dimethylformamide (DMF) solution, heated and dried at 90°C; then the sample was soaked in CH with a concentration of 10mg / mL 3 NH 3 In the isopropanol solution of 1, take it out after continuing for 15min, and clean it with isopropanol solution, after heating and drying at 90°C, the p...

Embodiment 2

[0074] Step 1: Clean the cut FTO ultrasonically with acetone and ethanol for 15 minutes respectively to remove organic matter on the surface, then wash it with deionized water, and finally put it in a UV-ozone cleaning machine for 30 minutes for surface modification;

[0075] Step 2: Hydrothermal growth of TiO on the pretreated FTO substrate 2 Nano stave. First, mix 25mL deionized water and 25mL concentrated hydrochloric acid to prepare an acidic solution; then add 0.8mL tetrabutyl titanate to the acidic mixed solution, transfer it to a high-pressure reactor after mixing; growth for 6 hours; finally annealed at 450°C for 2 hours to strengthen the crystallization, and the photoanode was prepared;

[0076] Step 3: Two-step preparation of CH on the photoanode prepared in Step 2 3 NH 3 PB 3 Perovskite film: First, spin-coat 1.2mol / LPbI on the surface of the photoanode 2 DMF solution, heated and dried at 90°C; then the sample was soaked in CH with a concentration of 10 mg / mL ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com