Preparation method of ferrocenyl carbon nanotube composite material and application thereof

A carbon nanotube, composite material technology, applied in nanotechnology, analytical materials, nanotechnology and other directions, can solve the problem of low sensitivity and selectivity of electrochemical sensing, high sensitivity, stability and repeatability, narrow linear response range, etc. problem, to achieve the effect of sensitive electrochemical response, wide linear response range, easy separation and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

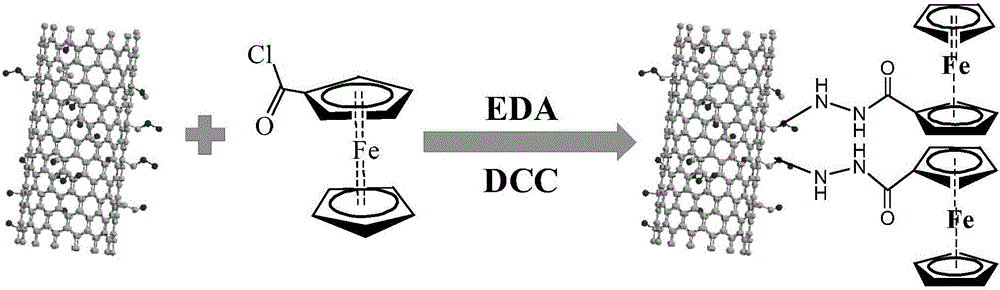

[0023] (1) Weigh 500 mg of carbon nanotubes and add them into a certain volume of 1:3 mixture of nitric acid and perchloric acid, place them in a powerful ultrasonic instrument for 7 hours, take them out and wash them with water twice until they are neutral, then Rinse with acetone and dry naturally in vacuo.

[0024] (2) Ultrasonic disperse 100 mg of purified oxidized multi-walled carbon nanotubes in 30 mL of anhydrous ethylenediamine for 30 min, then add 2.5 g of condensing agent N, N'-dicyclohexylcarbodiimide (DCC), and mix well , Heated to reflux in an oil bath at 120°C for 48h. After the reaction was completed, it was separated by centrifugation, the product was washed three times with absolute ethanol, and the product was vacuum-dried at 50° C. for 12 hours.

[0025] (3) Under anhydrous and oxygen-free conditions, weigh 600 mg of ferrocene monocarboxylic acid and dissolve it in 20 mL of anhydrous dichloromethane, stir to dissolve it fully, then quickly add 100 μL of pyr...

Embodiment 2

[0028] (1) Weigh 500 mg of carbon nanotubes and add them to a certain volume of 1:3 mixture of nitric acid and perchloric acid, place them in a powerful ultrasonic instrument for 5 hours, take them out and wash them with water twice until they are neutral, then Rinse with acetone and dry naturally in vacuo.

[0029] (2) Ultrasonic disperse 100 mg of purified oxidized multi-walled carbon nanotubes in 30 mL of anhydrous ethylenediamine for 30 min, then add 2.5 g of condensing agent N, N'-dicyclohexylcarbodiimide (DCC), and mix well , Heated to reflux in an oil bath at 120°C for 48h. After the reaction was completed, it was separated by centrifugation, the product was washed three times with absolute ethanol, and the product was vacuum-dried at 40° C. for 15 h.

[0030] (3) Under anhydrous and oxygen-free conditions, weigh 600 mg of ferrocenecarboxylic acid and dissolve it in 25 mL of anhydrous dichloromethane, stir to dissolve it fully, then quickly add 100 μL of pyridine and t...

Embodiment 3

[0033] (1) Weigh 500 mg of carbon nanotubes and add them to a certain volume of 1:3 mixture of nitric acid and perchloric acid, place them in a powerful ultrasonic instrument for 6 hours, take them out and wash them with water twice to neutral, then Rinse with acetone and dry naturally in vacuo.

[0034] (2) Ultrasonic disperse 100 mg of purified oxidized multi-walled carbon nanotubes in 30 mL of anhydrous ethylenediamine for 30 min, then add 2.5 g of condensing agent N, N'-dicyclohexylcarbodiimide (DCC), and mix well , Heated to reflux in an oil bath at 125°C for 48h. After the reaction was completed, it was separated by centrifugation, the product was washed three times with absolute ethanol, and the product was vacuum-dried at 50° C. for 12 hours.

[0035] (3) Under anhydrous and oxygen-free conditions, weigh 600 mg of ferrocene monocarboxylic acid and dissolve it in 30 mL of anhydrous dichloromethane, stir to fully dissolve, then quickly add 100 μL of pyridine and then sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com