Graphene modified hollow fiber membrane and preparation method thereof

A technology of graphene modification and fiber membrane, which is applied in the field of fiber membrane to improve surface performance, promote the development of water treatment technology, and improve the effect of chemical cleaning resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

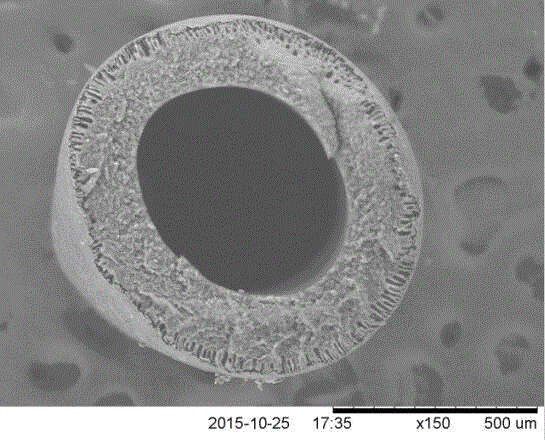

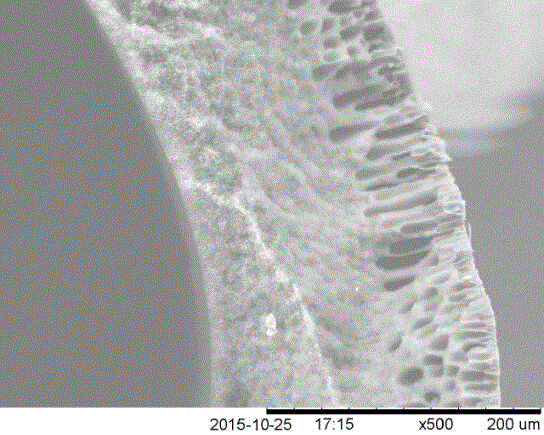

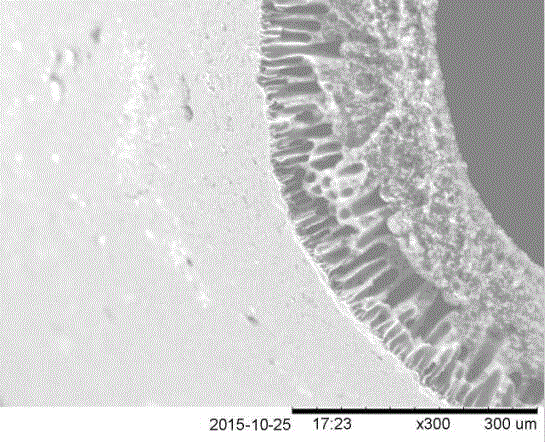

Image

Examples

preparation example Construction

[0056] A kind of preparation method of graphene modified hollow fiber membrane is characterized in that, comprises the following steps:

[0057] Step 1) Preparation of casting solution:

[0058] Premix, according to the mass percentage of the formula, add polyvinylidene fluoride resin 1~30wt%, hydrophilic modified resin 0.1~5wt%, graphene additive 1~2wt%, put it into the high mixer after weighing, and mix it at low speed for 30 seconds Then turn to high mixing for 1 minute, after standing still for 5 minutes, then add coupling agent 0.5~1.0wt%, turn to high mixing for 1 minute after low mixing for 30 seconds, high mixing spindle speed 1400rpm, let stand for 5 minutes and release the premix ;

[0059] Add solvent to dissolve, first add 2 / 3 of the solvent to the melting pot with a constant temperature of 70±5°C, start stirring, then add the above premix at a uniform speed, then add the remaining 1 / 3 of the solvent, stir and dissolve at a speed of 25-50rpm 8 to 10 hours;

[00...

Embodiment 1

[0072] According to formula mass percentage, polyvinylidene fluoride resin 17wt%, hydrophilic modified resin 0.5wt%, graphene additive 2wt%, wherein, graphene additive is made of graphene powder 35wt%, nano calcium carbonate 50wt%, colloidal silicon 5wt% , 10wt% antistatic agent, the antistatic agent is selected as 10% sodium chloride aqueous solution; after measuring, put it into the high mixer, mix at low speed for 30 seconds, then turn to high mixing for 1 minute, and after standing for 5 minutes, add 0.5 Wt% coupling agent γ-aminopropyltriethoxysilane KH550, mix at low speed for 30 seconds, then turn to high mixing for 1 minute, high mixing spindle speed 1400rpm, let stand for 5 minutes and release the premix; add 80wt% solvent To dissolve, when dissolving, first add 2 / 3 of the solvent to the melting pot with a constant temperature of 70±5°C, start stirring, then add the above premix at a uniform speed, and then add the remaining 1 / 3 of the solvent at a speed of 25-50rpm S...

Embodiment 2

[0075] According to formula mass percentage, polyvinylidene fluoride resin 17wt%, hydrophilic modified resin 0.5wt%, graphene additive 2wt%, wherein, graphene additive is made of graphene powder 33wt%, nano calcium carbonate 53wt%, colloidal silicon 7wt% , composed of 7wt% antistatic agent, the antistatic agent is selected as 10% sodium acetate aqueous solution; after measuring, put it into the high mixer, mix at low speed for 30 seconds, then turn to high mixing for 1 minute, and after standing for 5 minutes, add 0.5wt % of the coupling agent γ-aminopropyltriethoxysilane KH550, after 30 seconds of low mixing, turn to high mixing for 1 minute, high mixing spindle speed 1400rpm, let stand for 5 minutes and release the premix; add 80wt% solvent for Dissolving, when dissolving, first add 2 / 3 of the solvent to the melting pot with a constant temperature of 70±5°C, start stirring, then add the above premix at a uniform speed, then add the remaining 1 / 3 of the solvent, and stir at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com