Carbon-clad alloy material and fabrication method and application thereof

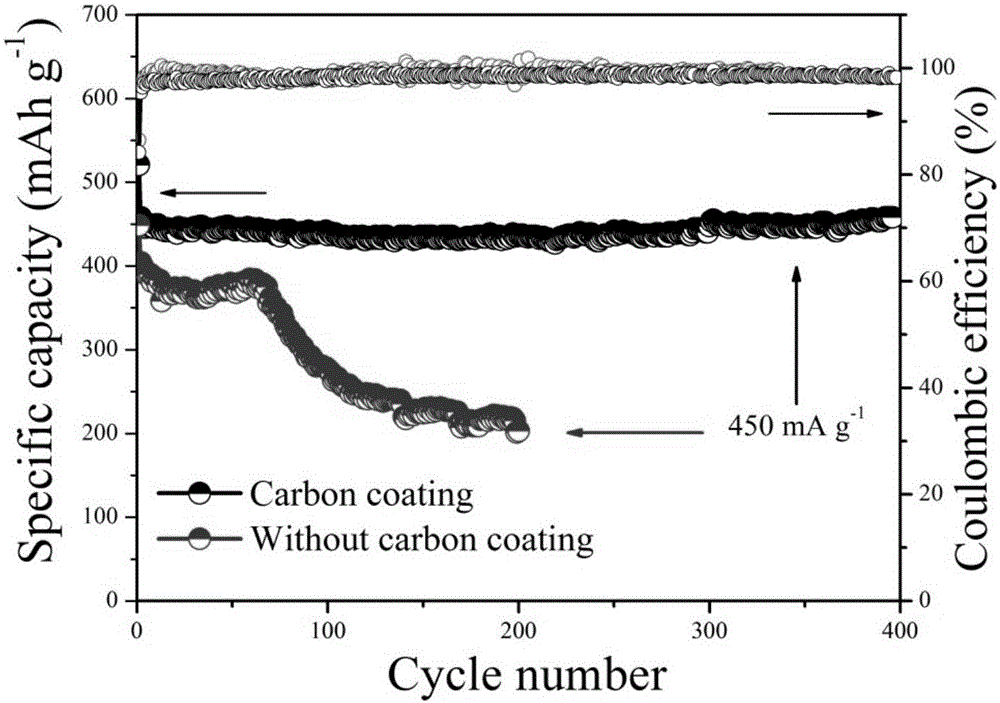

A technology of alloy materials and carbon coating, which is applied in the field of carbon coating alloy materials and their preparation, can solve the problems of difficult control and cumbersome preparation, and achieve the effects of avoiding pulverization and falling off, improving performance, and ensuring uniformity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

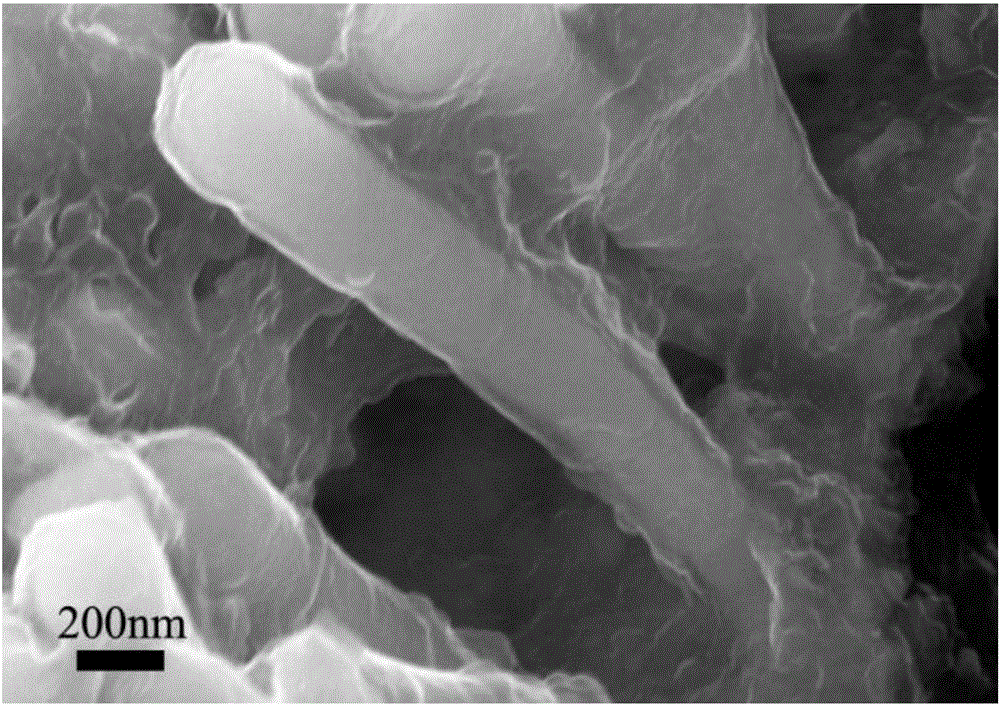

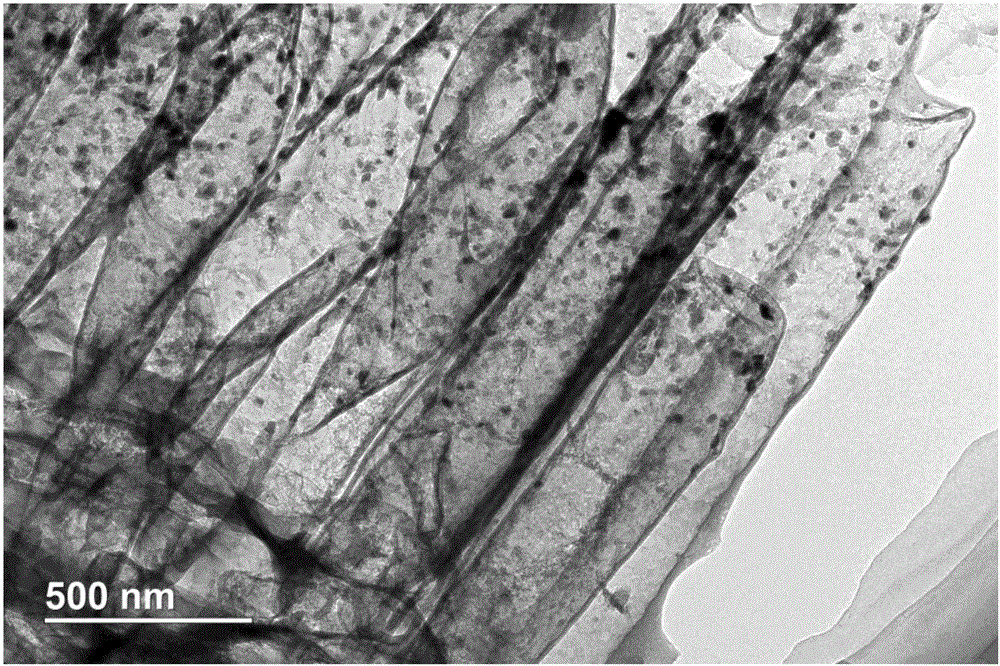

[0035] The carbon-coated alloy material in this example is a carbon-coated Sn—Ni alloy nanorod. Sn-Ni alloy nanorods are prepared by electrodeposition, and the morphology is nanorod-shaped. The carbon source used in the carbon coating layer is polycarbonate (abbreviated as PC) template. The specific preparation method is as follows:

[0036] Preparation of Sn-Ni nanorods: First, a dense copper film of four to five hundred nanometers is deposited on one side of Whatman's PC template by thermal evaporation to make it conductive, and then it is pasted with a water-based conductive adhesive On the copper foil, the evaporated copper film is opposite to the copper foil, and is in close contact, and the copper foil can be used as a current collector. After pasting and drying, fix it with copper tape to prevent it from falling off during electrodeposition in aqueous solution. The back of the copper foil is covered with a plastic film so that the back cannot be deposited. The plating ...

Embodiment 2

[0042] The carbon-coated alloy material in this example is carbon-coated Sn—Fe alloy nanoparticles. The specific preparation method is as follows:

[0043] Preparation of Sn-Fe alloy nanoparticles: Weigh metal micron Fe powder and Sn powder with a mass ratio of 60:40, mix them evenly, and briquette them. Install the raw material block in the DC arc plasma equipment, as the anode. Using a W rod as a cathode, fill it with a mixed gas of 0.03MPa argon and 0.04MPa hydrogen, start and stabilize the arc, and undergo evaporation, condensation, passivation and other processes to obtain Sn-Fe alloy nanoparticles.

[0044] Carbon coating: Weigh 20% to 30% of the weight of glucose of the prepared Sn-Fe alloy nanoparticles, place it in a mortar, add a small amount of water dropwise until the glucose dissolves, and then add a small amount of ethanol to make a glucose slurry; The prepared Sn-Fe alloy nanoparticles were added to the prepared glucose slurry, thoroughly ground, and then plac...

Embodiment 3

[0048] The carbon-coated alloy material in this example is carbon-coated Sn—Sb—Cu ternary alloy particles. The specific preparation method is as follows:

[0049] Preparation of Sn-Sb-Cu ternary alloy particles: Weigh Sn and Sb metal powders with a mass ratio of 1:1 and melt them into Sn-Sb alloys in a tube furnace, then take out and pulverize them into small particles of about 100 microns, and then accurately Sn-Sb-Cu ternary alloys can be obtained by weighing Cu powder with the same mass as Sn and Sb and the small Sn-Sb alloy particles prepared above, mixing them evenly, and ball milling in a planetary ball mill at 200r / min for 60h.

[0050] Carbon coating: Weigh 20% to 30% of the weight of glucose of the prepared Sn-Ni-Cu alloy nanoparticles, put it in a mortar, add a small amount of water dropwise until the glucose dissolves, and then add a small amount of ethanol to make a glucose slurry ; The prepared Sn-Sb-Cu ternary alloy particles were added to the prepared glucose s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com