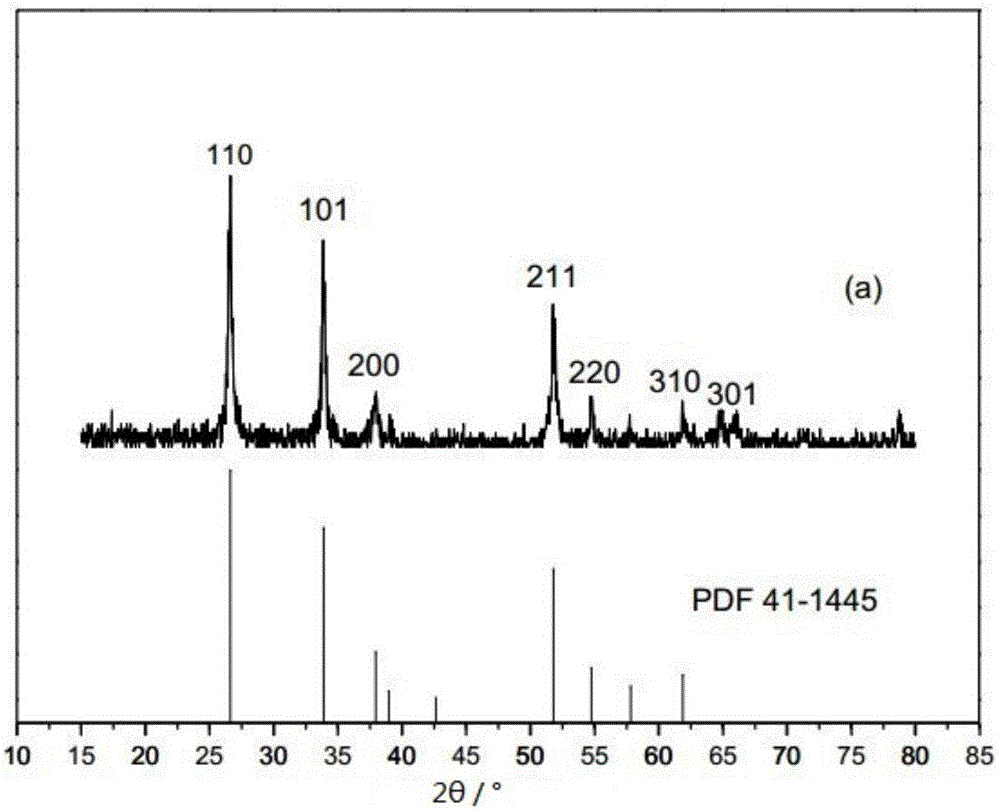

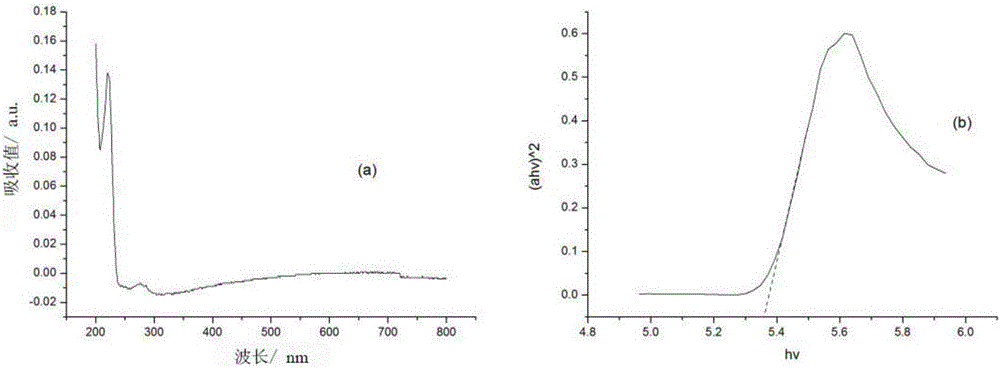

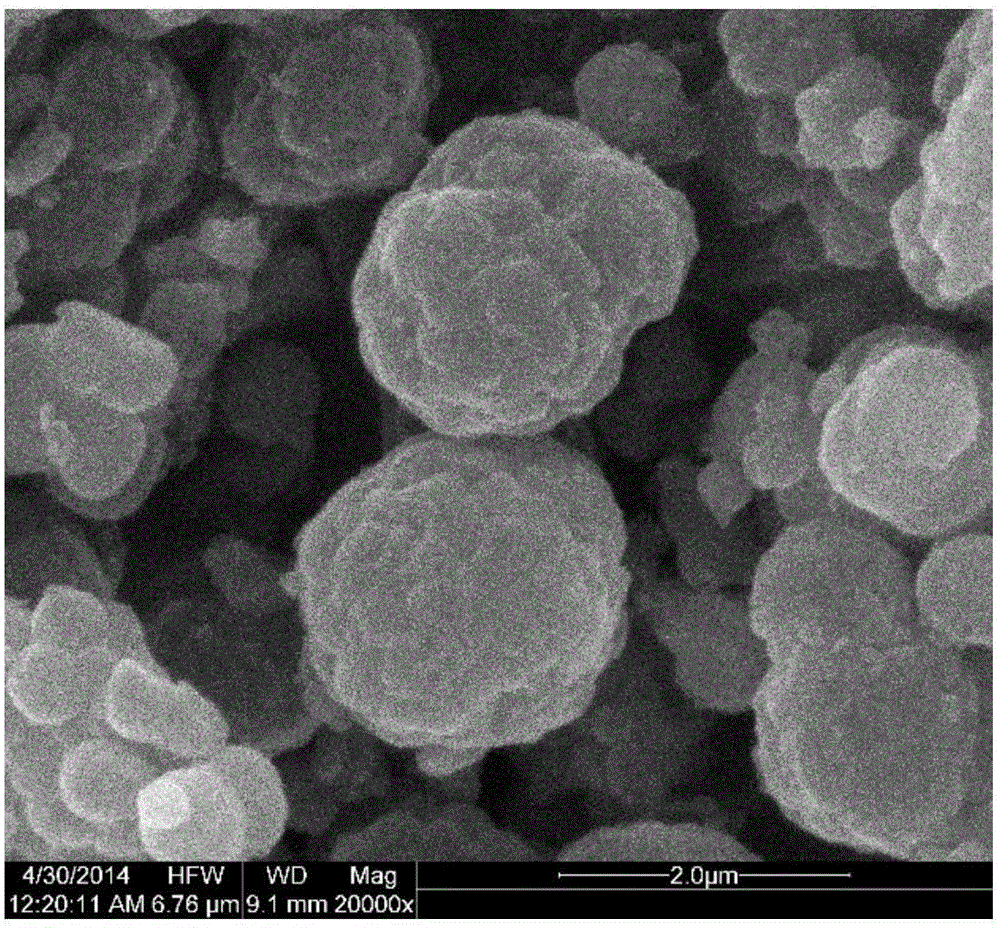

Nano SnO2 hollow microsphere, preparation method and applications thereof

A nano and microsphere technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of long preparation cycle and heat treatment time, and environmental pollution, so as to improve photocatalytic performance , to achieve large-scale production, the effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Get 1.752g tin chloride pentahydrate (SnCl 4 ·5H 2 O) and 1.712g sucrose (C 12 h 22 o 11 ) into 10 mL of deionized water, and stirred in a water bath at a constant temperature of 65°C for 20 min to fully dissolve the solid and volatilize the hydrogen chloride dissolved in the tin chloride. Pour the obtained mixed solution into the capacity cup of the polytetrafluoroethylene reaction kettle matched with the microwave digestion instrument, and carry out the microwave-assisted hydrothermal reaction. The filling degree is 60-80%, and the reaction conditions are set at 190° C. for 1 hour. After the reaction was completed and the reactor was naturally cooled, the precipitated part of the product was separated by a centrifuge, and washed three times with absolute ethanol and deionized water until the washing liquid was clear and transparent. Put the obtained product into a vacuum drying oven, and dry it at 70°C for 2 hours; after the product is cooled, put the product into...

Embodiment 2

[0048] Get the 1.495g potassium stannate (K 2 SnO 3 ·3H 2 O) and 1.712g sucrose (C 12 h 22 o 11 ) into 10 mL of deionized water, and stirred at a constant temperature of 65°C for 20 min to fully dissolve the solid and volatilize the hydrogen chloride dissolved in the tin chloride. The obtained mixed solution was then transferred to a capacity cup of a polytetrafluoroethylene reactor for microwave-assisted hydrothermal reaction under the reaction conditions of 160° C. for 1.5 h. After the reaction was completed and cooled naturally, the product was separated by a centrifuge to separate the precipitated part, and washed three times with absolute ethanol and deionized water until the washing liquid was clear and transparent. Put the obtained product into a vacuum drying oven and dry it at 70°C for 2 hours. After the product is cooled, put the product into a horse boiling furnace for calcination. The calcination condition is 650°C for 1 hour to obtain the product nano SnO 2 ...

Embodiment 3

[0050] Get the 1.495g potassium stannate (K 2 SnO 3 ·3H 2 O) and 1.712g sucrose (C 12 h 22 o 11 ) into 10 mL of deionized water, and stirred at a constant temperature of 65°C for 20 min to fully dissolve the solid and volatilize the hydrogen chloride dissolved in the tin chloride. The obtained mixed solution was then transferred to a capacity cup of a polytetrafluoroethylene reactor for microwave-assisted hydrothermal reaction under the reaction conditions of 220° C. for 0.5 h. After the reaction was completed and cooled naturally, the product was separated by a centrifuge to separate the precipitated part, and washed three times with absolute ethanol and deionized water until the washing liquid was clear and transparent. Put the obtained product into a vacuum drying oven and dry it at 70°C for 2 hours. After the product is cooled, put the product into a horse boiling furnace for calcination. The calcination condition is 450°C for 2.5 hours to obtain the product nano SnO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com