Method for preparing Fe/C composite porous structure material by using limonite

A porous structure, limonite technology, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problems of low calorific value of liquid fuel, complex composition, carbon deposition in boilers, etc. Achieve the effects of enhanced pyrolysis and gasification, large pore volume, and elimination of tar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment prepares Fe / C composite porous structure material according to the following steps:

[0026] (1) Select a limonite ore sample with an iron grade of 48.9%, crush it and pass through a 0.1mm sieve to obtain limonite powder; crush rape straw and pass through a 1mm sieve to obtain straw powder;

[0027] (2) Weighing the limonite powder and the straw powder according to the mass ratio of 1:3 and mixing them evenly to obtain the mixture;

[0028] (3) above-mentioned mixture is added in the hopper of screw extruder molding machine, extruded and formed into the rod-shaped particle of diameter 5mm;

[0029] (4) Roast the formed rod-shaped particles in a tube furnace at 750°C for 25 minutes in a hydrogen atmosphere, and then naturally cool to room temperature in an oxygen-free atmosphere to obtain Fe / C composite porous structure material.

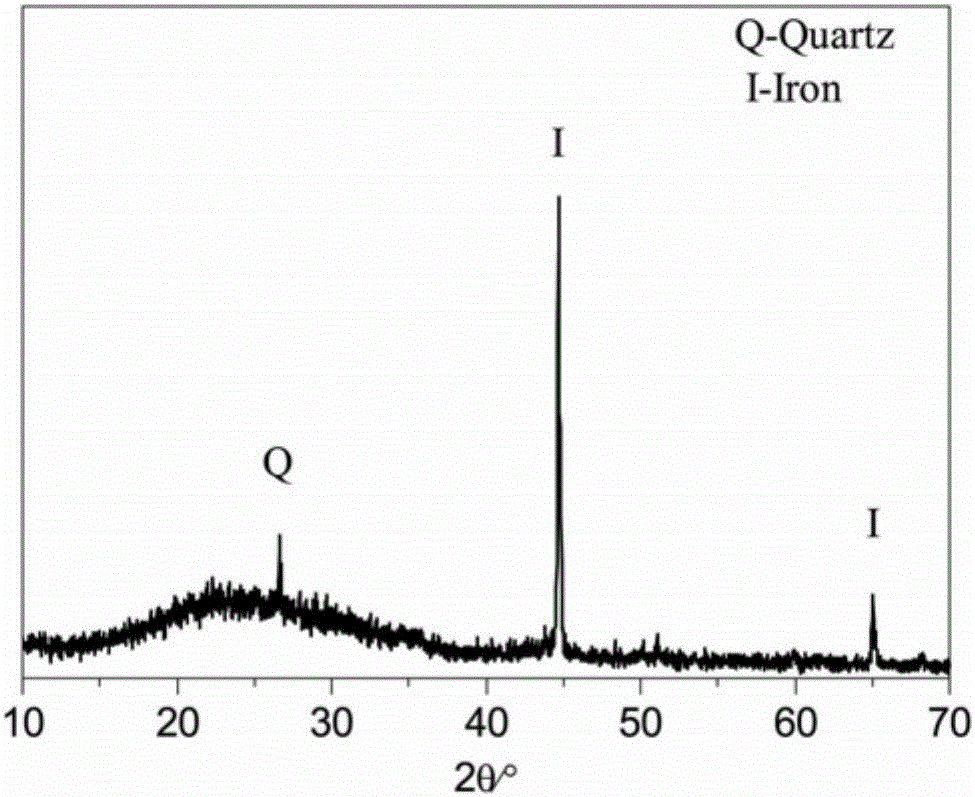

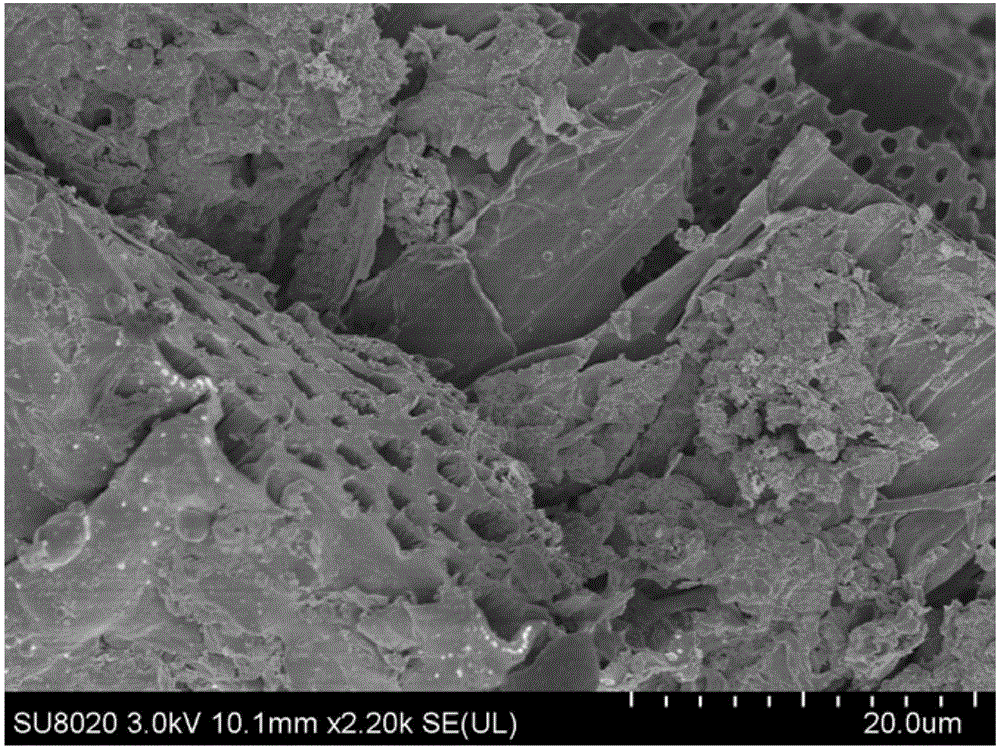

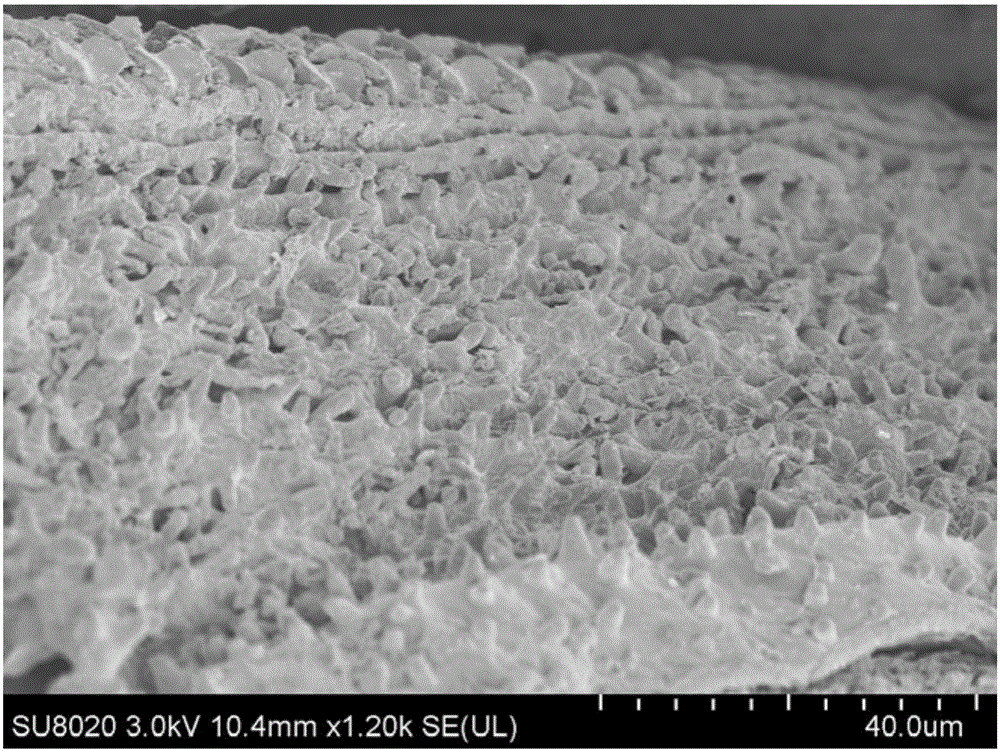

[0030] figure 1 The X-ray diffraction pattern of the Fe / C composite porous structure material powder prepared for this ex...

Embodiment 2

[0033] This embodiment prepares Fe / C composite porous structure material according to the following steps:

[0034] (1) Select a limonite ore sample with an iron grade of 40.31%, crush it and pass through a 0.1mm sieve to obtain limonite powder; crush rape straw and pass through a 1mm sieve to obtain straw powder;

[0035] (2) Weighing the limonite powder and straw powder according to the mass ratio of 1:5 and mixing them evenly to obtain the mixture;

[0036] (3) above-mentioned mixture is added in the hopper of screw extruder molding machine, extruded and formed into the rod-shaped particle of diameter 5mm;

[0037] (4) Roast the formed rod-shaped particles in a tube furnace at 650°C for 30 minutes in a hydrogen atmosphere, and then naturally cool to room temperature in an oxygen-free atmosphere to obtain Fe / C composite porous structure material.

[0038] After XRD analysis, the results showed that the impurity quartz in the original sample remained unchanged, and the iro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com