Method and system for preparing lithium carbonate or concentrated brine rapidly by high-temperature steam

A technology of high-temperature steam and concentrated brine, which is applied in steam distillation, separation methods, chemical instruments and methods, etc., can solve the problems of low grade, large consumption of chemicals, and high requirements for adsorbents, and achieve flexible and convenient use and high energy efficiency High and save equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

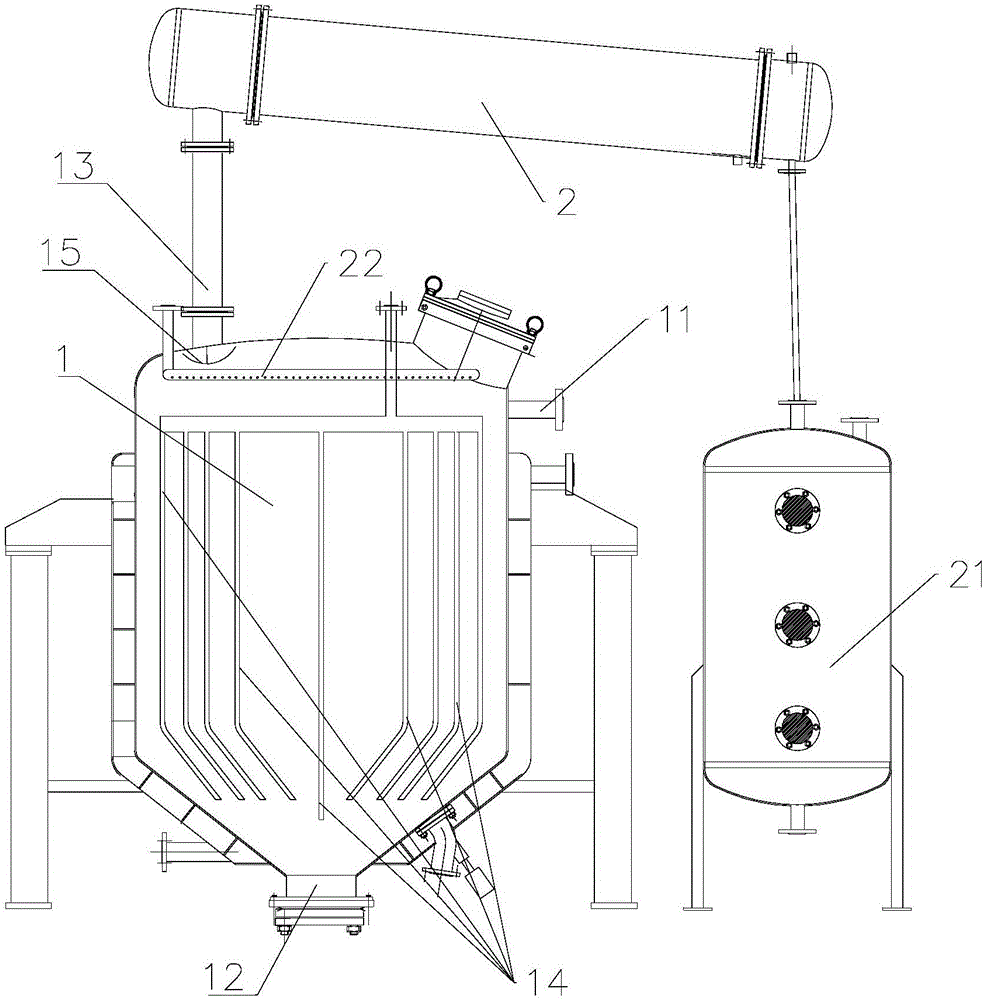

Image

Examples

Embodiment 1

[0052] 1) Pump 3082 L (3822 Kg) brine A into the reactor, preheat the brine to 80°C, brine A is rich in carbonate, and the lithium ion concentration is 1.82g / L;

[0053] 2) Pump the superheated steam above 250°C into the brine of the reaction kettle, and the generated steam will be condensed and discharged naturally through the condenser. After 19 minutes, the weight of the brine will stabilize and display 3481Kg;

[0054] 3) return the brine to the initial temperature, discharge the supernatant, transfer the lithium carbonate crystals to the lower reaction kettle and scrub with condensed pure water to obtain white ice cream-like hydrous lithium carbonate;

[0055] 4) The above-mentioned lithium carbonate containing water is dried to obtain lithium carbonate solid 24.89Kg, the grade reaches 95.2%, and the lithium precipitation rate reaches 79.4%.

Embodiment 2

[0059] 1) Pump 2216L (2592Kg) brine B into the reactor, preheat the brine to 80°C, brine B is rich in carbonate, and the lithium ion concentration is 2.55g / L;

[0060] 2) Pump superheated steam above 250°C into the brine of the reaction kettle, and after 15 minutes, the weight of the brine is stable and shows 2343Kg;

[0061] 3) return the brine to the initial temperature, discharge the supernatant, transfer the lithium carbonate crystals to the lower reaction kettle and scrub with condensed pure water to obtain white ice cream-like hydrous lithium carbonate;

[0062] 4) The above-mentioned aqueous lithium carbonate was dried to obtain 27.41 kg of solid lithium carbonate, the grade reached 99.47%, and the lithium precipitation rate reached 90.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com