Method for determining content of elemental mercury in metavanadate, and preparation method for sample solution

A metavanadate, sample solution technology, applied in the preparation of test samples, thermal excitation analysis, material excitation analysis and other directions, can solve the problems such as not seen, achieve less reagent consumption, low blank, low detection limit Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Digestion of ammonium metavanadate samples

[0045] Take by weighing sample 0.2000g ammonium metavanadate sample (hereinafter referred to as No. 1 sample) in Erlenmeyer flask, add 12mL water to rinse bottle wall, disperse sample and accelerate dissolving sample by shaking or vibrating action under room temperature environment; Then in Add 6mL nitric acid and 6mL hydrogen peroxide to the solution, heat the metavanadate solution to 65°C by direct heating on a low-temperature electric heating plate or indirect heating in a hot water bath, and keep at this temperature for 3 minutes. After the digestion test solution is cooled to room temperature, dilute with water to volume and mix in a 100mL volumetric flask.

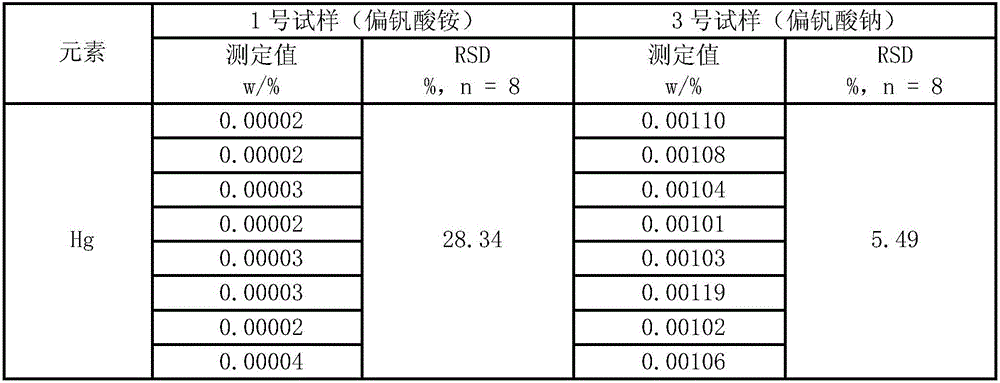

[0046] Determination of Mercury Content in Ammonium Metavanadate Sample Solution by ICP-MS

[0047] Inductively coupled plasma mass spectrometry (ICP-MS) was used as the detection method, and through the connection mode of the online internal standard mixer, the...

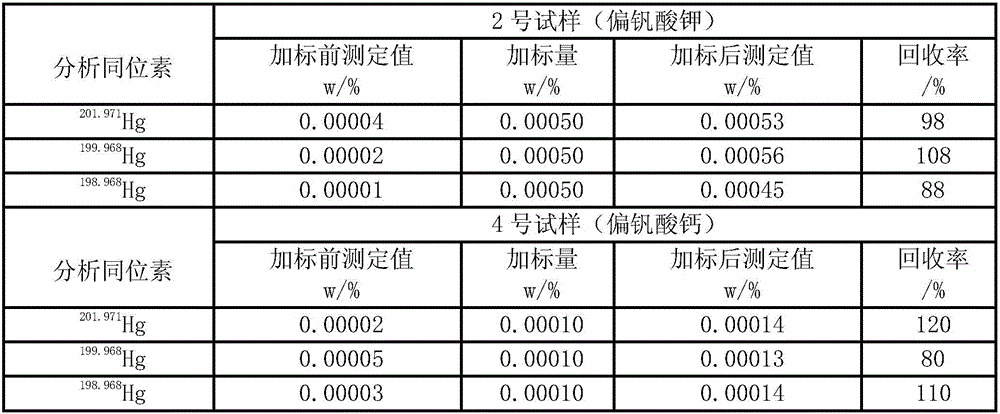

Embodiment 2

[0051] The sample to be digested is 0.1000g potassium metavanadate sample (hereinafter referred to as No. 2 sample), the consumption of water is 6mL, the consumption of concentrated nitric acid is 3mL, and the consumption of hydrogen peroxide is 3mL, and the temperature and the time of solution heating reaction are respectively 60°C and 2min, the final dilution constant volume is 50mL, and the concentration of rhodium Rh internal standard calibration standard solution used is 1ng / mL.

[0052] Besides, the potassium metavanadate sample was digested in the same manner as in Example 1 and the solution was detected by ICP-MS.

Embodiment 3

[0054] The sample to be digested is 0.1500g sodium metavanadate sample (hereinafter referred to as No. 3 sample), the consumption of water is 9mL, the consumption of concentrated nitric acid is 4.5mL, the consumption of hydrogen peroxide is 4.5mL, the temperature and time of solution heating reaction 63° C. and 2.5 minutes respectively, the final dilution constant volume is 100 mL, and the concentration of rhodium Rh internal standard calibration standard solution used is 3 ng / mL.

[0055] Besides, the sodium metavanadate sample was digested in the same manner as in Example 1 and the solution was detected by ICP-MS.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com