Air purifying material and preparation method and application thereof

A technology for purifying air and substrates, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of poor purification effect and low purification efficiency of air conditioners, and achieve the effect of low purification cost, easy molding, and firm shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Weigh 20g of potassium permanganate and 30g of ammonium oxalate, add 1L of water, sonicate until the potassium permanganate and ammonium oxalate are completely dissolved, and place the resulting solution in a 90°C water bath for 10 hours. The produced manganese oxide is centrifuged, washed and dried in an oven at 105°C to obtain the manganese dioxide catalyst. Grind, take powder larger than 100 mesh, and set aside.

[0033] Weigh 20g of manganese dioxide powder catalyst, add 20g of acrylic adhesive, 40g of deionized water, mix to obtain a slurry with a solid content of about 25%, adjust the pH of the slurry to 9, and then remove the foam on the surface of the slurry.

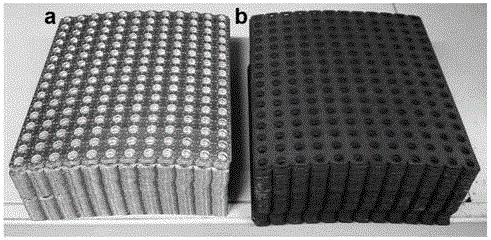

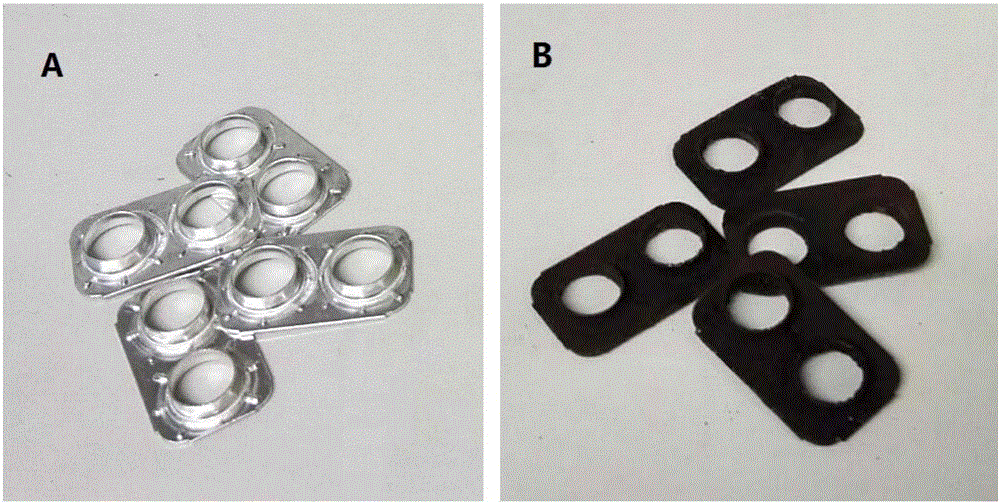

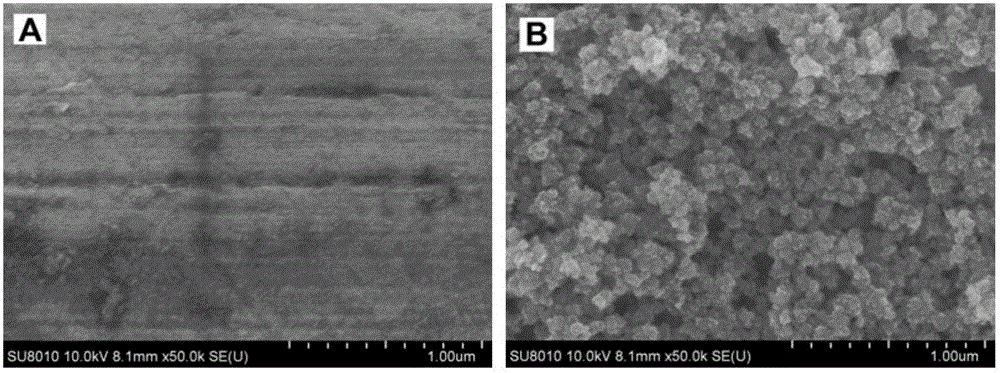

[0034] The aluminum-based fins with a mass of 0.74g and a thickness of 0.3mm were immersed in an alcohol solution and ultrasonically washed for 20min to remove the grease on the surface. Take it out and ultrasonically wash it with deionized water until the surface of the aluminum substrate is completely ...

Embodiment 2

[0038] Weigh 25g of potassium permanganate, add 1L of water, sonicate until the potassium permanganate is completely dissolved, then add 1.5L of methanol, and place the resulting solution in a water bath at 45°C for 6 hours. The produced manganese oxide is centrifuged, washed and dried in an oven at 105°C to obtain the manganese dioxide catalyst. Grind, take powder larger than 100 mesh, and set aside.

[0039] Weigh 25g of manganese dioxide powder catalyst, add 10g of polyurethane binder and 20g of deionized water, and mix to obtain a slurry with a solid content of about 45.5%, and adjust the pH of the slurry to 7.

[0040] Immerse an aluminum substrate with a mass of 0.74g and a thickness of 0.3mm in an alcohol solution and ultrasonically wash it for 20 minutes, take it out and ultrasonically wash it with deionized water until the surface of the aluminum substrate is completely wetted (the effect of the load is better if the continuity of the wetting film is maintained for mo...

Embodiment 3

[0046] According to (Appl.Catal.B: Environ., 2016, 189, 210), weigh 25g of potassium permanganate, 20g of manganese sulfate monohydrate, add 1L of water, sonicate until the drug is completely dissolved, and place the resulting solution in a hydrothermal The reaction was carried out at 140°C for 12 hours in the reactor. The generated manganese dioxide is centrifuged, washed and dried in an oven at 105°C to obtain a manganese dioxide catalyst capable of deozone. Grind, take powder larger than 100 mesh, and set aside.

[0047] Weigh 10 g of manganese dioxide powder catalyst, add 80 g of acrylic binder and 100 g of deionized water, and mix to obtain a slurry with a solid content of about 5.3%, and adjust the pH of the slurry to 5.

[0048] Immerse an aluminum substrate with a mass of 0.74g and a thickness of 0.3mm in an alcohol solution and ultrasonically wash it for 20 minutes, take it out and ultrasonically wash it with deionized water until the surface of the aluminum substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com