A full temperature range pressure swing adsorption method for producing pure oxygen

A pressure swing adsorption, full temperature range technology, applied in chemical instruments and methods, oxygen preparation, oxygen/ozone/oxide/hydroxide, etc., can solve single problems, reduce workload, high yield, The effect of shortening the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

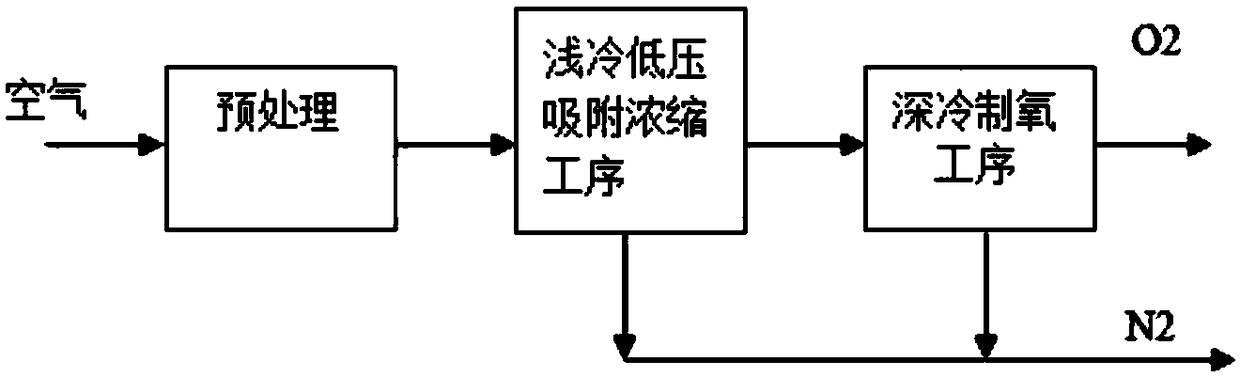

[0044] Such as figure 1 As shown, a full temperature range pressure swing adsorption (FTrPSA) method for producing pure oxygen, the steps of the method are as follows:

[0045] (1) Pretreatment process;

[0046] a. Dust removal, the dust and mechanical particles in the raw material air are removed through the air filter, so as to obtain dust-free air, in addition to nitrogen (N 2 ) and oxygen (O 2 ) In addition to dust, moisture, carbon dioxide (CO 2 ), hydrocarbons (CnHm) and other impurities, the dust and mechanical particles are removed through the air filter; the content of solid impurities such as dust in the air is generally 0.005-0.02g / m 3 , the particle size of the dust is usually below 0.15mm; these solid impurities will increase the friction of the cylinder, blades and valves of the air compressor, and the solid dust brought to the cooler will cause heat transfer surface pollution, resulting in a decrease in the heat transfer coefficient. After the filter is remo...

Embodiment 2

[0060] On the basis of the full temperature range pressure swing adsorption (FTrPSA) method for producing pure oxygen described in Example 1, the air processing capacity and dust removal unit remain unchanged, and the dust-free air is sent into the air turbine for compression Compressed to 0.5-0.6MPa and then sent to the air cooling tower for cleaning, and pre-cooled to -60--50°C, and then entered into the 6 tower with an operating temperature of -60--50°C and an operating pressure of 0.5-0.6MPa The shallow cold and low-pressure adsorption and concentration process consists of obtaining oxygen-enriched gas with an oxygen content of 70-80% from the non-adsorption phase, and then passing through a process with an operating temperature of -60--50°C and an operating pressure of 0.5-0.6MPa. The shallow-cooled low-pressure molecular sieve adsorption impurity removal system composed of two towers, the purified (dried) oxygen-rich gas is cooled to close to the liquefaction temperature ...

Embodiment 3

[0062] On the basis of the full temperature range pressure swing adsorption (FTrPSA) method for producing pure oxygen described in Example 1, the air processing capacity and dust removal unit remain unchanged, and the dust-free air is sent into the air turbine for compression Compressed to 0.1-0.2MPa and then sent to the air cooling tower for cleaning, and pre-cooled to -20--10°C, and then entered into the 6 tower with an operating temperature of -20--10°C and an operating pressure of 0.1-0.2MPa The shallow cold and low-pressure adsorption and concentration process consists of obtaining oxygen-enriched gas with an oxygen content of 60-70% from the non-adsorption phase, and then passing through a process with an operating temperature of -20--10°C and an operating pressure of 0.1-0.2MPa. The shallow-cooled low-pressure molecular sieve adsorption impurity removal system composed of two towers, the purified (dried) oxygen-rich gas is cooled to close to the liquefaction temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com