Phenol-containing wastewater treatment process

A treatment process, a technology for phenol wastewater, applied in water/sewage treatment, water/sludge/sewage treatment, water pollutants, etc., can solve problems such as failure, degradation, and unsatisfactory treatment effects, and achieve low price and high degradation efficiency Improves and prevents excessive corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

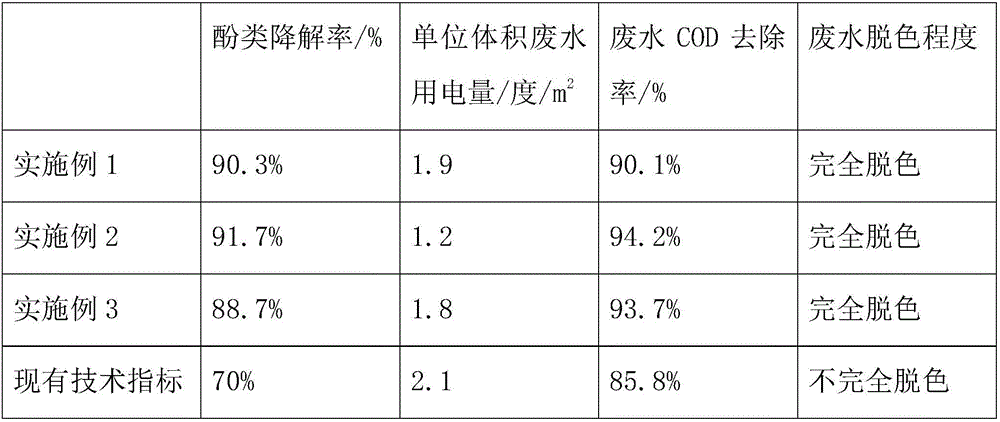

Examples

Embodiment 1

[0019] A kind of phenolic waste water treatment process is characterized in that, its step comprises:

[0020] (1) Electrode pretreatment

[0021] Take the titanium plate and polish it with sandpaper, rinse it with distilled water first, then put it into absolute ethanol for ultrasonic cleaning for 3-5 minutes, take it out and rinse it with distilled water, then rinse the titanium plate with hydrofluoric acid for 4 seconds, and finally rinse it with distilled water for later use;

[0022] (2) Preparation of degraded anode electrodes

[0023] Dissolve 1mM copper nitrate and 10mM urea in 80mL of ultrapure water (in 5cm 2 Titanium plate meter) to form a blue transparent solution, put the titanium plate vertically into the hydrothermal reaction kettle, transfer the solution to the reaction kettle so that the liquid level is higher than the height of the titanium plate, and heat the reaction kettle at 120°C After 12 hours, take out the titanium plate, rinse it with distilled wate...

Embodiment 2

[0027] A kind of phenolic waste water treatment process is characterized in that, its step comprises:

[0028] (1) Electrode pretreatment

[0029] Take the titanium plate and polish it with sandpaper, rinse it with distilled water first, then put it into absolute ethanol for ultrasonic cleaning for 4 minutes, take it out and rinse it with distilled water, then rinse the titanium plate with hydrofluoric acid for 4 seconds, and finally rinse it with distilled water for later use;

[0030] (2) Preparation of degraded anode electrodes

[0031] Dissolve 1mM copper nitrate and 10mM urea in 80mL of ultrapure water (in 5cm 2 Titanium plate meter) to form a blue transparent solution, put the titanium plate vertically into the hydrothermal reaction kettle, transfer the solution to the reaction kettle so that the liquid level is higher than the height of the titanium plate, and heat the reaction kettle at 130°C After 10 hours, take out the titanium plate, rinse it with distilled water,...

Embodiment 3

[0035] A method for researching anthracnose pollution-free prevention and control technology, is characterized in that, its step comprises:

[0036] (1) Electrode pretreatment

[0037] After polishing the titanium plate with sandpaper, rinse it with distilled water first, then put it into absolute ethanol for ultrasonic cleaning for 5 minutes, take it out and rinse it with distilled water, then rinse the titanium plate with hydrofluoric acid for 4 seconds, and finally rinse it with distilled water for later use;

[0038] (2) Preparation of degraded anode electrodes

[0039] Dissolve 1mM copper nitrate and 10mM urea in 80mL of ultrapure water (in 5cm 2 Titanium plate meter) to form a blue transparent solution, put the titanium plate vertically into the hydrothermal reaction kettle, transfer the solution to the reaction kettle so that the liquid level is higher than the height of the titanium plate, and heat the reaction kettle at 150°C After 10 hours, take out the titanium pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com