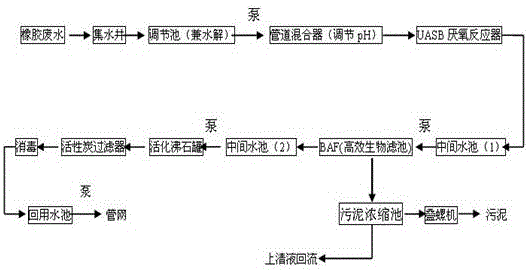

Rubber wastewater treatment process

A technology of rubber wastewater and treatment process, applied in water/sewage treatment, biological water/sewage treatment, neutralized water/sewage treatment, etc. The effect of improving biodegradability and reducing processing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Step A pretreatment: the rubber wastewater flows into the water collection well after the large particles of impurities are removed by the artificial grid, and the dosing system and its pH meter are installed in front of the water collection well, and the water collection well is equipped with a submersible sewage pump; The pool is equipped with a submersible mixer to mix the water quality and remove some organic matter under the action of facultative organic matter;

[0039] Step B removes most of the organic matter and total phosphorus: the wastewater treated in step A is pumped into the UASB tank, and after anaerobic digestion, the UASB tank is composed of a sludge reaction zone, a gas-liquid-solid three-phase separator (including a sedimentation zone) The air chamber consists of three parts;

[0040] Step C to remove COD and BOD: the wastewater treated in step B flows into the intermediate pool (1) by itself, stays for 1.3 hours, and then lifts it to the BAF reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com