Plastic track material for stadiums

A technology for sports fields and plastic runways, applied in building thermal insulation materials, building components, buildings, etc., can solve the problems of insufficient rebound rate, low tensile strength, low elongation at break, etc. The effect of corrosion resistance and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

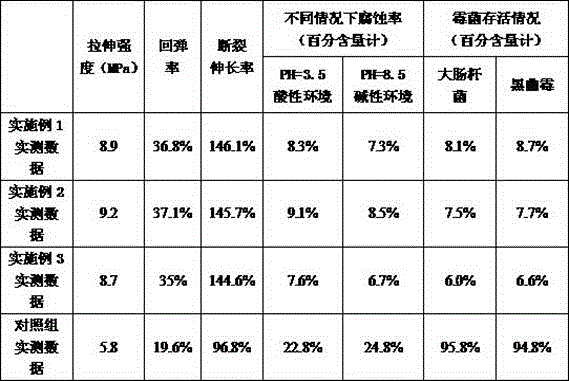

Examples

Embodiment 1

[0023] The plastic runway material of sports field in the present embodiment comprises the material of following mass components: 18 parts of triethylene glycol dimethacrylate, 20 parts of dodecyl benzyl ammonium chloride, 16 parts of sodium dehydroacetate 14 parts of barium stearate, 20 parts of EPDM rubber, 16 parts of zinc oxide powder, 14 parts of petroleum pitch, 20 parts of sodium hydroxymethyl cellulose, 16 parts of polyurethane, 14 parts of antimony trioxide powder, fluorine 20 parts of pyridineurea, 16 parts of avermectin, 16 parts of diethylenetriamine, 14 parts of isobutyltriethoxysilane, 20 parts of coconut oil fatty acid diethanolamide, 16 parts of bentonite powder, 14 parts of chitosan, 20 parts of sodium lauryl sulfate, 16 parts of barium sulfate, 14 parts of silica sol, 20 parts of aluminum hydroxide powder, and 16 parts of polyvinyl chloride.

[0024] The barium sulfate is composed of powders with three particle sizes and meshes, the particle sizes and meshes ...

Embodiment 2

[0036] The plastic runway material of sports field in the present embodiment comprises the material of following mass components: 20 parts of triethylene glycol dimethacrylate, 22 parts of dodecyl benzyl ammonium chloride, 18 parts of sodium dehydroacetate 16 parts of barium stearate, 22 parts of EPDM rubber, 18 parts of zinc oxide powder, 16 parts of petroleum pitch, 22 parts of sodium hydroxymethyl cellulose, 18 parts of polyurethane, 16 parts of antimony trioxide powder, fluorine 22 parts of pyridineurea, 18 parts of abamectin, 18 parts of diethylenetriamine, 16 parts of isobutyltriethoxysilane, 22 parts of coconut oil fatty acid diethanolamide, 18 parts of bentonite powder, 16 parts of chitosan, 22 parts of sodium lauryl sulfate, 18 parts of barium sulfate, 16 parts of silica sol, 22 parts of aluminum hydroxide powder, and 18 parts of polyvinyl chloride.

[0037] The barium sulfate is composed of powders with three particle sizes and meshes, the particle sizes and meshes a...

Embodiment 3

[0049] The plastic runway material of sports field in the present embodiment comprises the material of following mass components: 22 parts of triethylene glycol dimethacrylate, 24 parts of dodecyl benzyl ammonium chloride, 20 parts of sodium dehydroacetate 18 parts of barium stearate, 24 parts of EPDM rubber, 20 parts of zinc oxide powder, 18 parts of petroleum pitch, 24 parts of sodium hydroxymethyl cellulose, 20 parts of polyurethane, 18 parts of antimony trioxide powder, fluorine 24 parts of pyridineurea, 20 parts of abamectin, 20 parts of diethylenetriamine, 18 parts of isobutyltriethoxysilane, 24 parts of coconut oil fatty acid diethanolamide, 20 parts of bentonite powder, 18 parts of chitosan, 24 parts of sodium lauryl sulfate, 20 parts of barium sulfate, 18 parts of silica sol, 24 parts of aluminum hydroxide powder, and 20 parts of polyvinyl chloride.

[0050] The barium sulfate is composed of powders with three particle sizes and meshes, the particle sizes and meshes a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com