Recombined hansenula polymorpha fermentation technology

A technology of Hansenula yeast and fermentation process, which is applied in the field of fermentation engineering, and can solve the problems of reduced digestibility, increased cost, waste of phosphorus sources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

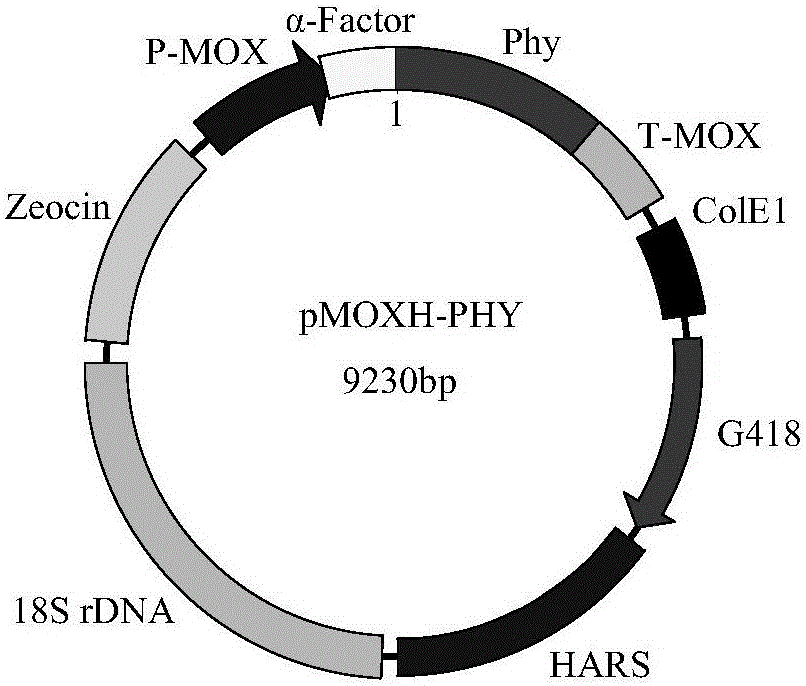

[0025] Example 1 Recombinant Phytase Expression System—Construction of Recombinant Hansenula

[0026] In this example, a secreted expression vector is used, and the recombinant plasmid construction process is as follows:

[0027] (1) Construction of the backbone vector pKO carrying the Kan resistance gene expression cassette and the ColE1 replicon region

[0028] Using the pPIC3.5k plasmid (Invitrogen Company) as a template, the ColEI replicon region with a size of 890bp was amplified with two primers, and at the same time, a BglII restriction site was introduced upstream, and a KpnI restriction site was introduced downstream; pPIC3.5k The plasmid (Invitrogen Company) was used as a template, and the Kan resistance gene expression cassette with a size of 1220bp was amplified with primers. At the same time, a BglII restriction site was introduced upstream, and a KpnI restriction site was introduced downstream. The Kan resistance gene is expressed in Escherichia coli Express res...

Embodiment 2

[0040] Example 2 Recombinant Hansenula fermentation process

[0041] 1. Preparation of seed solution

[0042] Take a 2mL production strain prepared in Example 1 from the working seed bank in the -70°C refrigerator, and the final concentration of glycerol is 17%. After thawing, inoculate into 5mL YPD medium according to 2% volume ratio, culture at 200rpm shaker at 30°C for 20-24 hours to OD 600nm =8~15, inoculate into 200mL BMGY medium after passing the test, the inoculum size of each bottle is 5mL, and cultivate in a shaker at 30°C and 200rpm for 20-24 hours to OD 600nm = 15-25, after passing the test, it will be used as a fermented seed liquid.

[0043] 2. Fermentation tank fermentation

[0044] The seed liquor is fermented as follows:

[0045] (1) Prepare 3L of basal salt medium, sterilize in a 7.5L automatic control fermenter, and cool to 30°C. The formula of the basic salt medium is as follows: ammonium dihydrogen phosphate 14.3g / L, magnesium sulfate heptahydrate 3.2g...

Embodiment 3

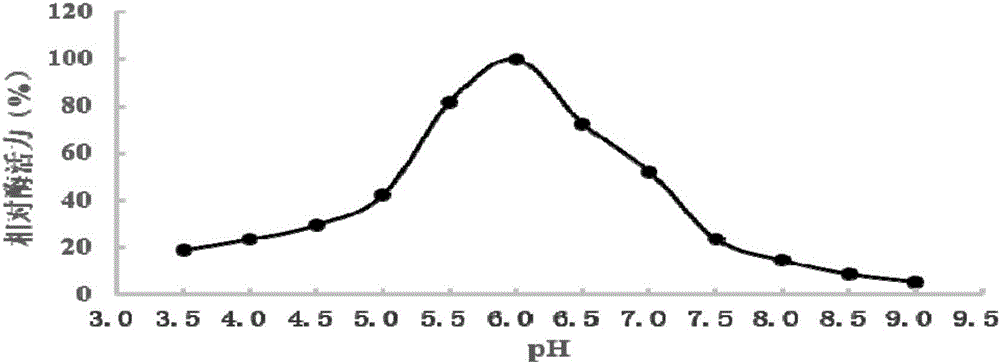

[0066] Embodiment 3 The property determination of recombinant phytase

[0067] 1. The optimal pH determination method of recombinant phytase is as follows:

[0068] The fermentation broth was subjected to enzymatic reaction at different pH to determine its optimum pH. Substrate sodium phytate was used to measure phytase activity at 37°C with different pH buffers. The results showed that the optimum pH of phytase was 6.0, and the enzyme had better catalytic activity at pH 4.0-7.5. ( figure 2 )

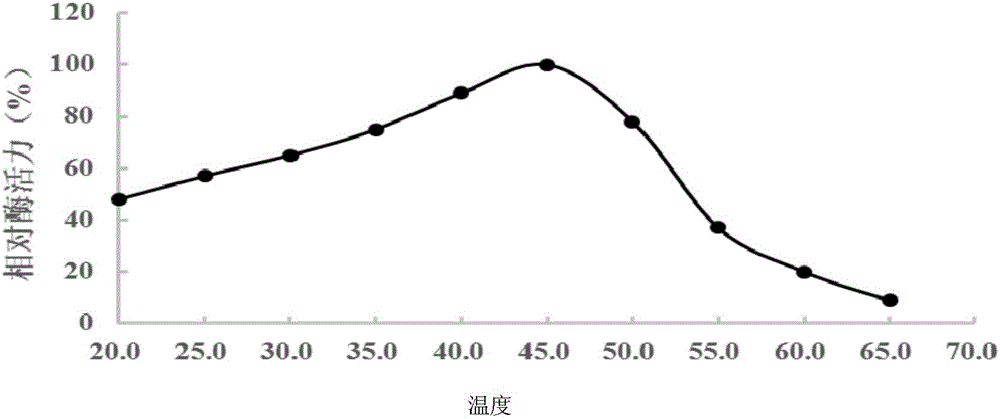

[0069] 2. The optimal temperature and thermostability determination method of phytase is as follows:

[0070] The determination of the optimal temperature of phytase is to carry out enzymatic reaction in pH5.5 buffer system and different temperatures. After heat treatment in water baths of different temperatures for 5 minutes, quickly put into ice water to cool down. Another unheated control group was set up. The enzyme activity was determined according to the conventional metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com