Method for measuring hydrogen isotope ratio of ethanol in grape wine

A technology of isotope ratio and hydrogen isotope, which is applied in the field of research and daily inspection, can solve the problems of inaccurate measurement of ethanol hydrogen isotope, long pretreatment time, and high requirements for operators, so as to avoid isotope fractionation, small sample consumption and long analysis time short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]Embodiment one: installation packing is the capillary chromatographic column of bonded styrene-divinylbenzene porous polymer (embodiment two and embodiment three also adopt same capillary chromatographic column), determine ethanol retention time:

[0035] a) Using absolute ethanol, water, acetone and methanol as experimental materials, take each pure reagent and put them into 2mL sample bottles and mix them in equal proportions, put them into 2mL sample bottles, and put them in the sample tray for determination;

[0036] b) Set GC condition parameters: injection volume 0.1uL; injection port temperature: 200°C; constant flow mode: 1.2mL / min; split injection mode: 100:1; / 160℃ / 4min / / 15 / / 210℃ / 1min;

[0037] c) Confirm that the working environment, airtightness, and vacuum degree of the ion chamber of the stable isotope ratio mass spectrometer meet the requirements, and then test the instrument to measure H 2 The precision and stability of δD in the medium, adjust the ion s...

Embodiment 2

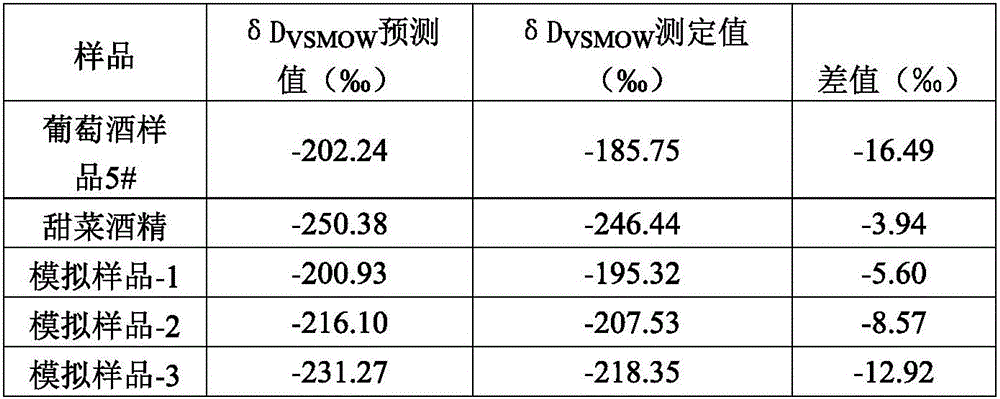

[0044] a) 5 wine samples and 1 beet alcohol sample were diluted 100 times with acetone,

[0045] Put it into a 2mL sample bottle, put it in the sample tray and wait for the determination;

[0046] b) Set GC condition parameters: injection volume 1uL; injection port temperature: 200°C; constant flow mode: 1.0mL / min; split injection mode: 20:1; 78℃ / 1min / / 15 / / 200℃ / 10min;

[0047] c) Confirm that the working environment, airtightness, and vacuum degree of the ion chamber of the stable isotope ratio mass spectrometer meet the requirements, and then test the instrument to measure H 2 The precision and stability of δD in the medium, adjust the ion source parameter value if necessary;

[0048] d) Set cracking tube parameters: cracking tube temperature is 1420°C;

[0049] e) Optimizing the reaction conditions of the pyrolysis tube: after the temperature of the pyrolysis tube reaches 1420°C, a certain volume of CH is introduced 4 The gas is coated with a layer of C inside the cracki...

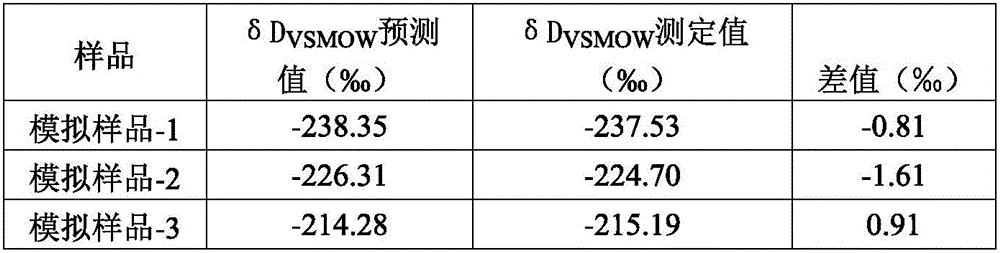

Embodiment 3

[0057] a) Choose wine sample 5# and edible alcohol from sugar beet as experimental objects, according to the ethanol content in the wine: beet alcohol = 1: 3 (referred to as "simulated sample-1"), 1: 1 (referred to as "simulated sample-1") 2") and 3:1 (referred to as "simulated sample-3"), add beet alcohol to the wine to prepare a simulated sample, dilute it with acetone 100 times, put it into a 2mL sample bottle, put it in the sample tray and wait Determination;

[0058] b) Set GC condition parameters: injection volume 1uL; injection port temperature: 200°C; constant flow mode: 1.0mL / min; split injection mode: 20:1; 78℃ / 1min / / 15 / / 200℃ / 10min;

[0059] c) Confirm that the working environment, airtightness, and vacuum degree of the ion chamber of the stable isotope ratio mass spectrometer meet the requirements, and then test the instrument to measure H 2 The precision and stability of δD in the medium, adjust the ion source parameter value if necessary;

[0060] d) Set cracki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com