Loaded type catalyst and preparation method and application thereof

A supported catalyst and catalyst technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of amino hydroxyl compounds, etc., to achieve the effects of many application times, good catalyst stability and good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

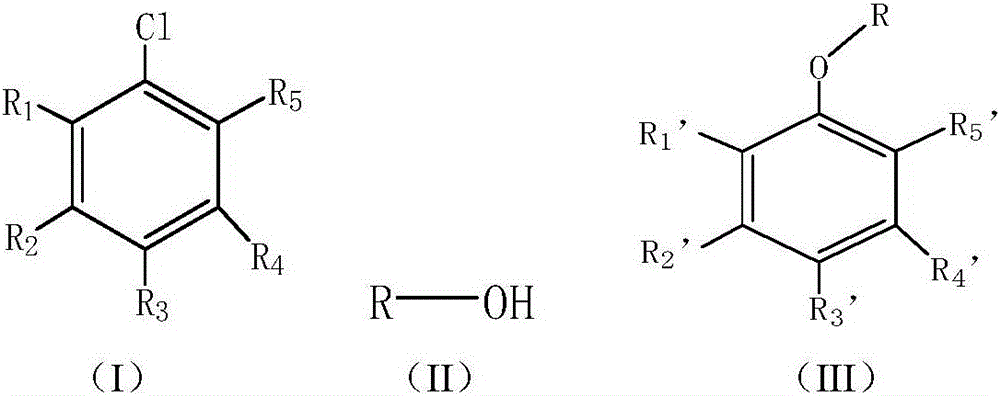

Method used

Image

Examples

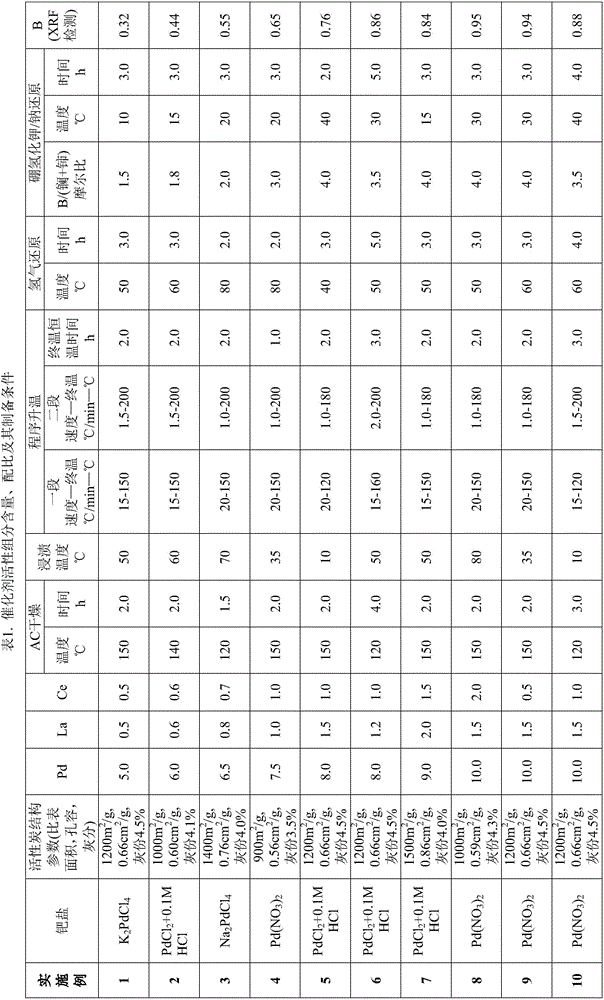

Embodiment 1 Embodiment 10

[0052] The content, proportion and preparation conditions of the catalyst active components are provided, as shown in Table 1. The specific preparation process of the catalyst is as follows: 4.0-12.0%: 0.2-3.5%: 0.2-3.5% of the carrier mass are respectively weighed soluble palladium salt (see Table 1), lanthanum nitrate and cerium nitrate according to the metal mass content percentage, configured as The aqueous solution having the same volume as the total pore volume of the activated carbon (see Table 1 for details) was placed in a constant pressure funnel and inserted into a three-necked flask. Then dry the activated carbon in the three-necked flask for 1.5-4.0 hours in a vacuum state of -0.08--0.1MPa and 120.0-180.0°C. After drying, lower the temperature to 5.0-80.0°C, open the valve of the constant pressure funnel, and fully wet the aqueous solution containing palladium, lanthanum and cerium with the activated carbon. Then in a vacuum anaerobic state (between -0.08—-0.1MPa...

Embodiment 10

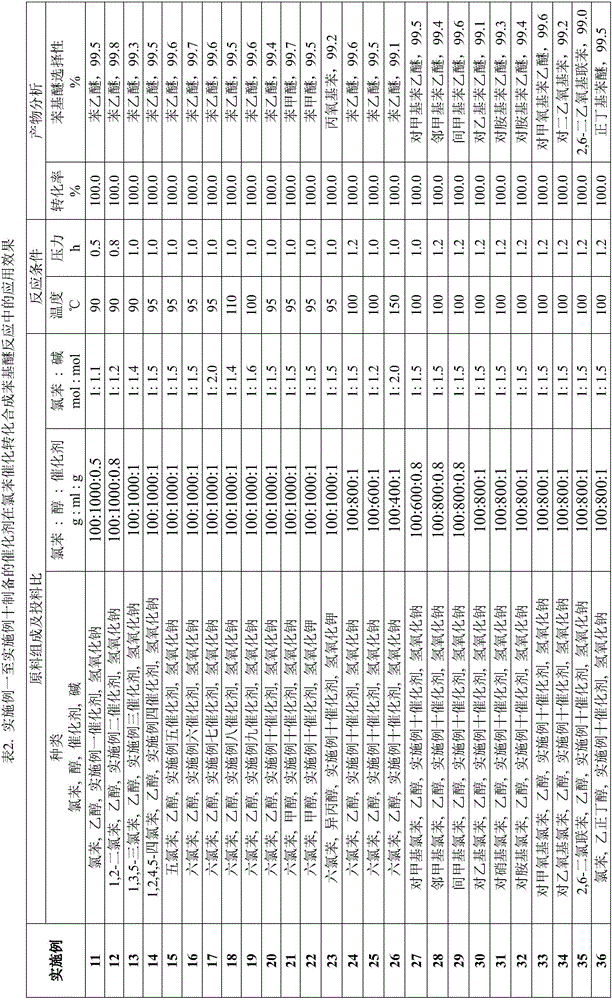

[0056] Table 3 shows the application of the catalyst prepared in Example 10 to the catalytic conversion of hexachlorobenzene to prepare phenetole.

[0057] The specific hydrogenation conversion process is as follows: put hexachlorobenzene, ethanol, and catalyst in a ratio of 100g:600ml:1.0g, and the molar ratio of chlorine atoms contained in sodium hydroxide to hexachlorobenzene is 1.5, and put into a 500ml high-pressure hydrogenation reactor Inside, the feeding volume is 70%. Close the reactor, replace the air in the reactor with nitrogen, then replace the nitrogen with hydrogen, start stirring, maintain the reaction temperature at about 90-110°C, and the hydrogen pressure between 0.5-1.2MPa, until no hydrogen is absorbed, stop the reaction, filter catalyst. Sodium chloride is precipitated by low-temperature evaporation, and ethanol and sodium hydroxide are recovered for reuse. The filtrate was analyzed by gas chromatography.

[0058]

[0059]

[0060] Table 3. Catal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com