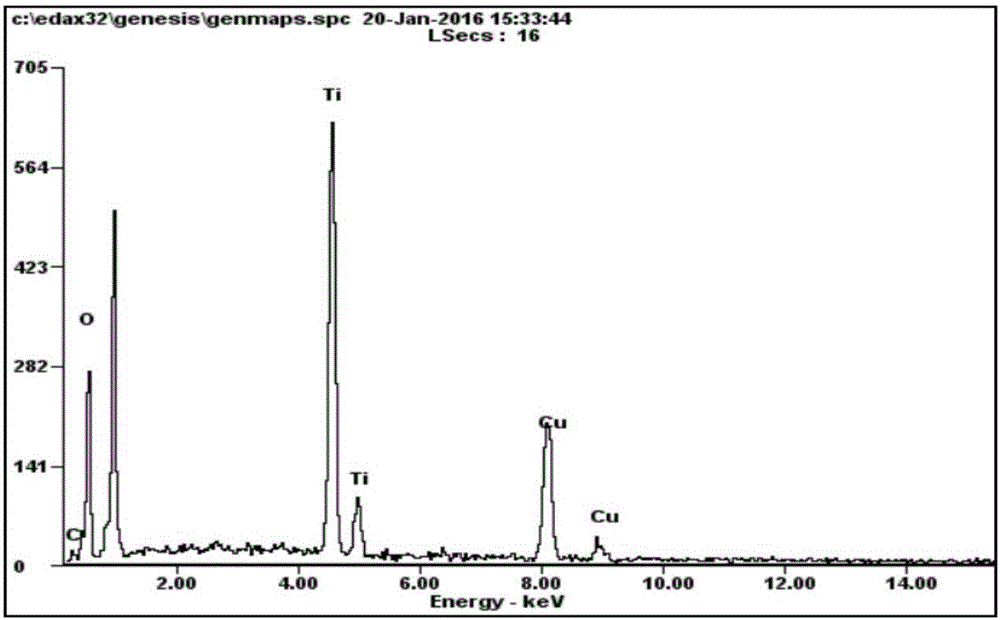

Preparation method of copper oxide/titanium dioxide composite nanotube arrays

A nanotube array, titanium dioxide technology, applied in nanotechnology, liquid chemical plating, electrolytic coatings, etc., can solve the problems of troublesome powder catalyst recycling, low catalytic efficiency, low catalytic ability, etc., to improve photocatalysis effect, improve the catalytic effect, and complete the growth of the crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a copper oxide / titanium dioxide composite nanotube array, comprising the following steps:

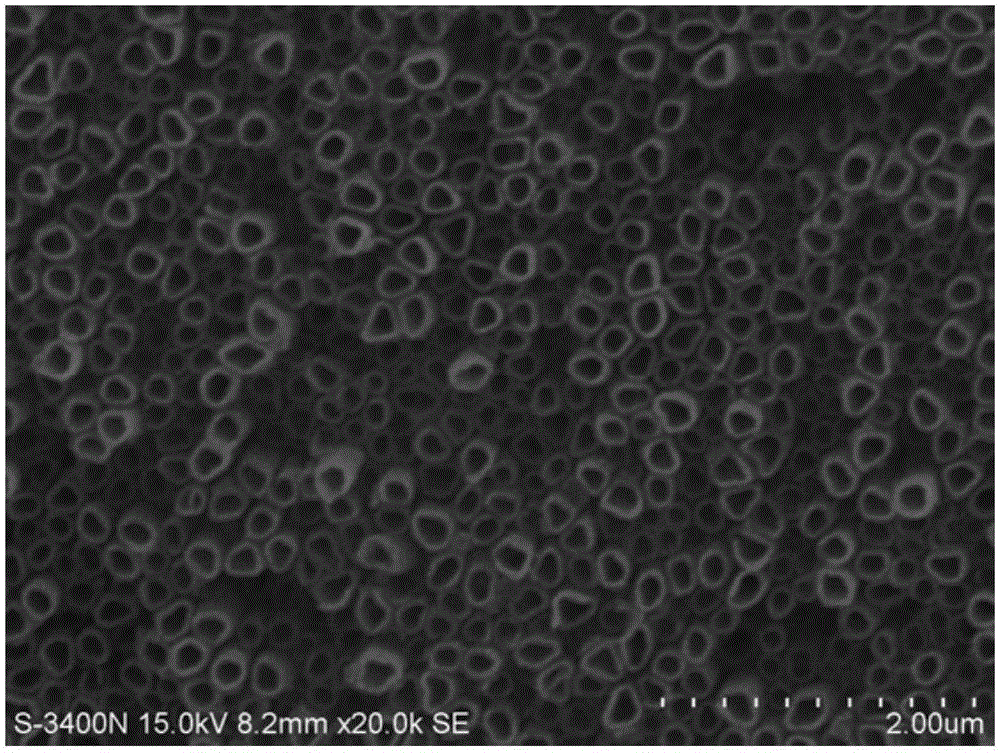

[0031] (1) Anodization: Cut the titanium sheet into small pieces, clean the surface, and anodize in the electrolyte for a period of time to obtain a titanium dioxide nanotube array, wherein the electrolyte is a solution with a volume ratio of glycerol and water of 5:1, and at the same time Ammonium fluoride with a mass fraction of 0.5% is dissolved in the electrolyte; during anodization, the cleaned titanium sheet is used as the anode, connected to the positive electrode of the power supply; the graphite electrode is used as the cathode, connected to the negative electrode of the power supply, and the temperature of the electrolyte is 20°C. The time is 4h, the electrolysis voltage is 40V;

[0032] (2) Chemical deposition: the prepared nanotube arrays are immersed in soluble copper sulfate solution, and the standing time is 40s, then the nanotubes are taken ...

Embodiment 2

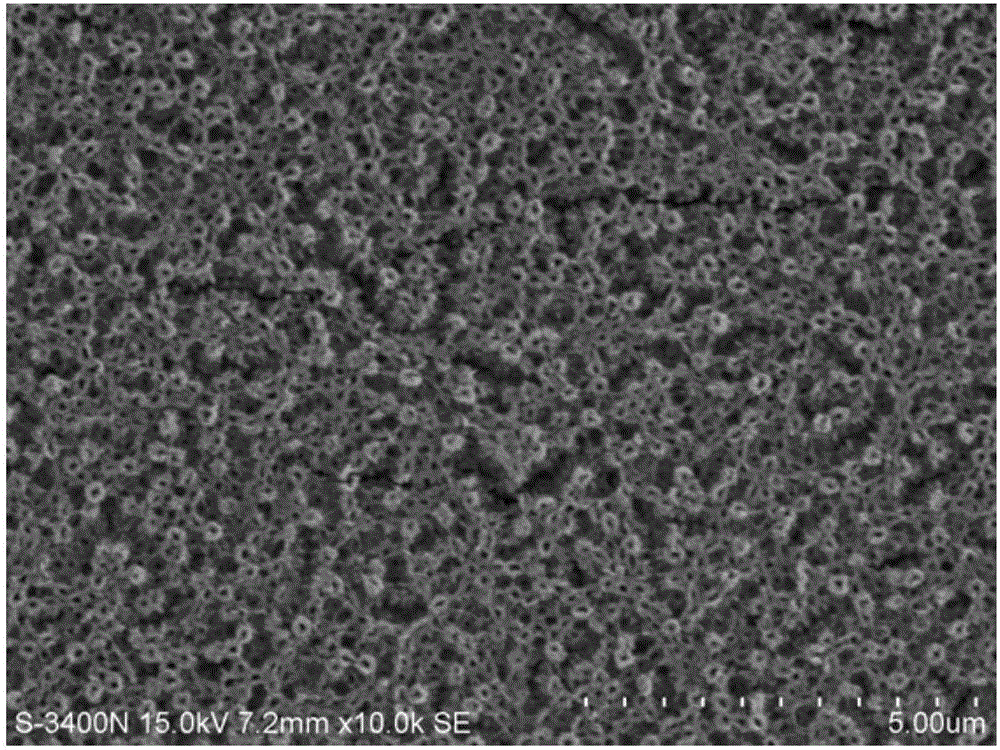

[0035] A method for preparing a copper oxide / titanium dioxide composite nanotube array, comprising the following steps:

[0036] (1) Anodization: Cut the titanium sheet into small pieces, clean the surface, and anodize in the electrolyte for a period of time to obtain a titanium dioxide nanotube array, wherein the electrolyte is a solution with a volume ratio of ethylene glycol and water of 8:1, and at the same time Sodium fluoride with a mass fraction of 1.0% is dissolved in the electrolyte; during anodization, the cleaned titanium sheet is used as the anode, connected to the positive electrode of the power supply; the graphite electrode is used as the cathode, connected to the negative electrode of the power supply, and the temperature of the electrolyte is 30 ° C. The time is 8h, the electrolytic voltage is 50V;

[0037] (2) chemical deposition: the prepared nanotube arrays are immersed in the cupric chloride solution, the standing time is 60s, then the nanotubes are taken ...

Embodiment 3

[0040] A method for preparing a copper oxide / titanium dioxide composite nanotube array, comprising the following steps:

[0041] (1) Anodization: Cut the titanium sheet into small pieces, clean the surface, and anodize in the electrolyte for a period of time to obtain a titanium dioxide nanotube array, wherein the electrolyte is a solution with a volume ratio of dihydroxyacetone and water of 6.5:1, At the same time, potassium fluoride with a mass fraction of 0.75% was dissolved in the electrolyte; during anodization, the cleaned titanium sheet was used as the anode, connected to the positive electrode of the power supply; the graphite electrode was used as the cathode, connected to the negative electrode of the power supply, and the temperature of the electrolyte was 25°C. The electrolysis time is 6h, and the electrolysis voltage is 45V;

[0042](2) chemical deposition: the prepared nanotube array is immersed in copper nitrate solution, and the standing time is 50s, then the n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com