A multifunctional modified polymer lithium ion battery binder and its application in electrochemical energy storage devices

A polymer binder, lithium-ion battery technology, applied in electrochemical generators, battery electrodes, polysaccharide adhesives, etc. Insufficient junction strength and elasticity, limited use range, etc., to achieve the effects of reducing electrochemical interface impedance, improving uniformity and flatness, and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) First, 1 g of sodium carboxymethylcellulose was pre-dissolved in 50 ml of deionized water (DI-Water), and fully stirred under an argon atmosphere for 0.5 to 2.5 hours to remove oxygen to obtain a uniform and well-dispersed solution; The stirring speed is 100-500 rpm;

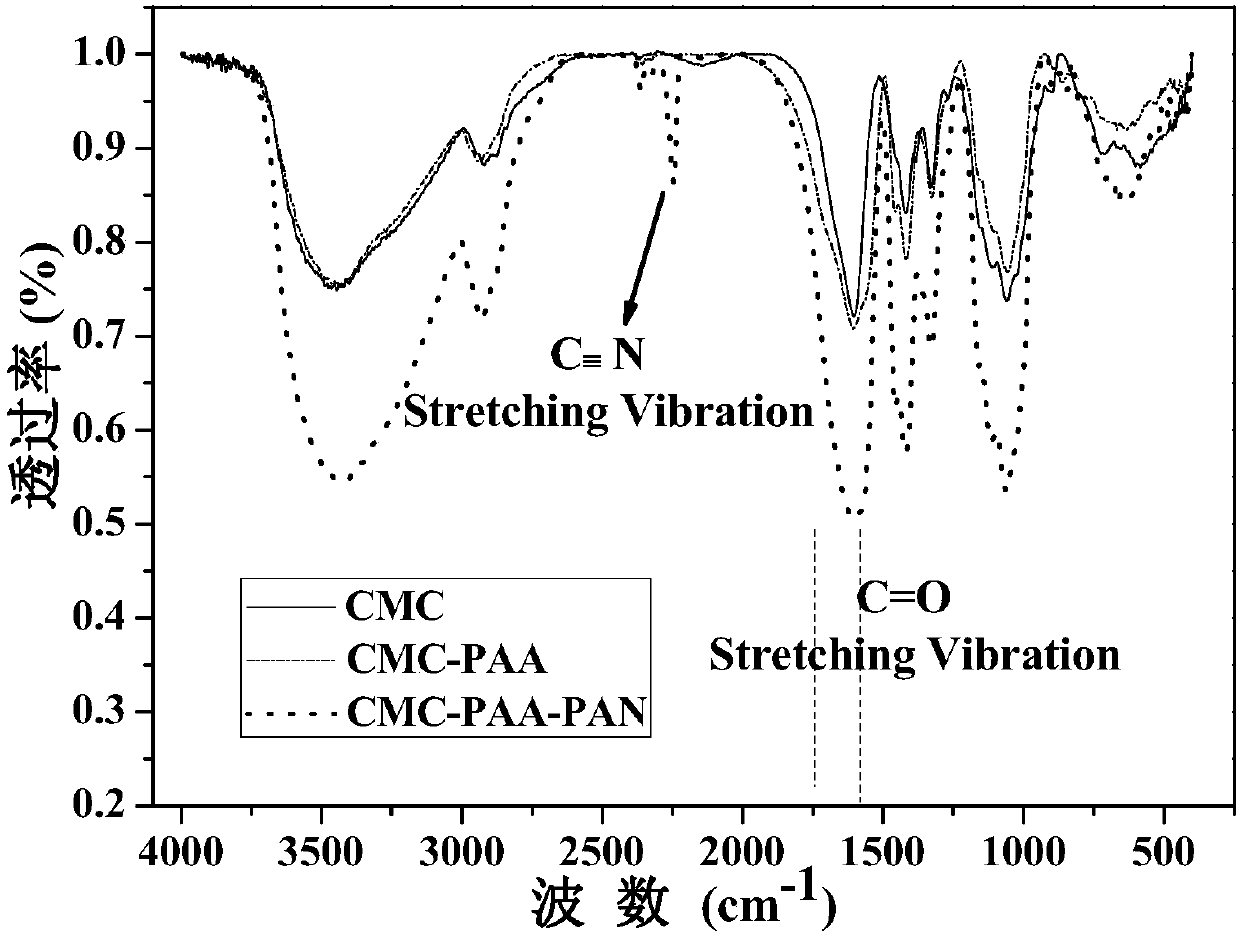

[0054] (2) Weigh 0.1g (NH 4 ) 2 S 2 o 8 Add the initiator to the solution obtained in step (1), and stir thoroughly to obtain a mixed solution; then add 2.5g of acrylic acid monomer, adjust the reaction temperature to 55°C, keep stirring, and react at a constant temperature for 2.5h to obtain a transparent and uniform glue. It is a multifunctional modified polymer lithium-ion battery binder; the solid content is 6.5wt%, and the viscosity is 164.5mPa.s, see Table 1, and its infrared spectrum can be found in figure 1 .

Embodiment 2

[0056] Referring to Example 1, the difference is that the monomers added are 2.5 g of acrylic acid and 0.84 g of acrylonitrile. The initiator used is 0.1g (NH 4 ) 2 S 2 o 8 / 0.03g NaHSO 3 , to obtain light white and slightly transparent emulsion, which is the binder of multifunctional modified polymer lithium ion battery, with a solid content of 8wt%, and a viscosity of 432.1mPa.s, see Table 1, and its infrared spectrum is shown in figure 1 .

Embodiment 3

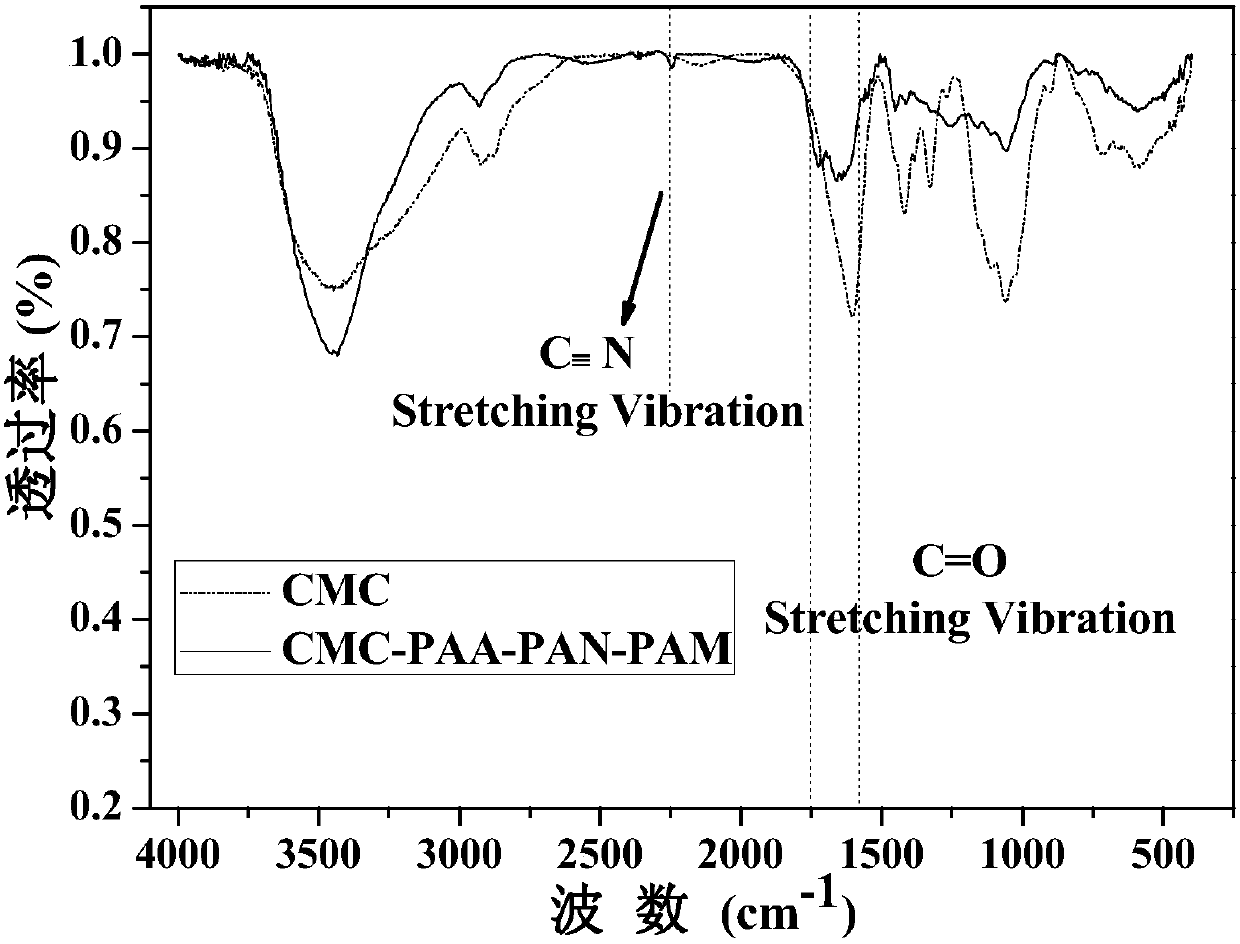

[0058] Referring to Example 1, the difference is that the added monomers are 2.5g of acrylic acid, 0.84g of acrylonitrile and 1g of acrylamide. The initiator used is 0.1g (NH 4 ) 2 S 2 o 8 / 0.03g NaHSO 3 , the temperature of the reaction is 60°C, and a transparent slightly white emulsion is obtained, which is a binder for multi-functional modified polymer lithium-ion batteries, with a solid content of 9.6wt% and a viscosity of 1377.4mPa.s, see Table 1, its infrared Spectrum see figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com