Preparation method of Astragalus polysaccharide-iron

A technology of astragalus polysaccharide iron and astragalus polysaccharide, which is applied in the field of preparation of polysaccharide iron complexes, can solve the problems of high production cost, and achieve the effects of low production cost, simple process flow and low biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

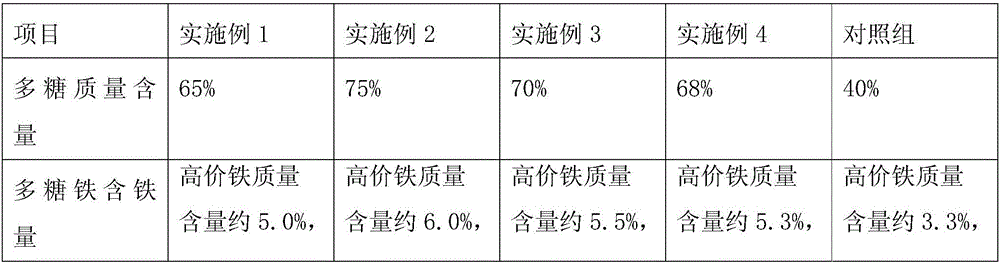

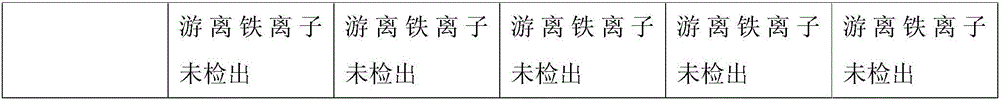

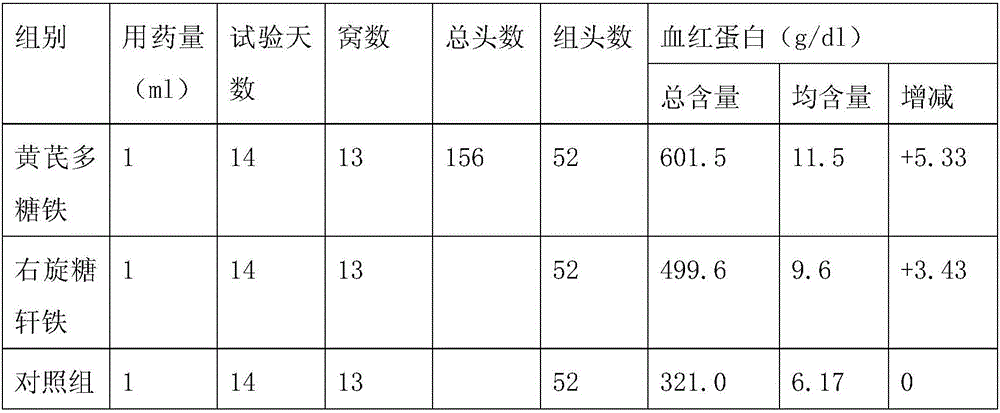

Examples

Embodiment 1

[0026] A preparation method for preparing astragalus polysaccharide iron, comprising the following specific steps:

[0027] (1) Extraction and purification of Astragalus polysaccharides: take Astragalus medicinal material and crush it into coarse powder, then reflux extraction with distilled water with a weight ratio of 1:5 for 2 hours, a total of 3 times, and then add 50% ethanol to the reflux liquid extracted by reflux The solution was subjected to microwave treatment for 3 times under the conditions of power of 500W and pressure of 0.1MPa, each time for 50s, and microwave treatment was stopped for 20s after each microwave treatment to obtain a microwave extract, which was passed through a 60-mesh copper sieve to remove coarse residue and collected Merge the filtrates, use a tubular centrifuge to remove small impurities in the astragalus polysaccharide, and use a 0.2 micron ceramic membrane module to micro-filter to remove macromolecular substances. Perform circulating ultra...

Embodiment 2

[0030] A preparation method for preparing astragalus polysaccharide iron, comprising the following specific steps:

[0031] (1) Extraction and purification of Astragalus polysaccharides: take Astragalus medicinal material and crush it into coarse powder, then reflux extraction with distilled water with a weight ratio of 1:8 for 2 hours, a total of 3 times, and then add 60% ethanol to the reflux liquid extracted by reflux The solution was subjected to microwave treatment 3 times under the conditions of power of 800W and pressure of 0.3MPa, each time for 50s, and microwave treatment was stopped for 30s after each microwave treatment to obtain a microwave extract, which was passed through a 120-mesh copper sieve to remove coarse residue, collected Merge the filtrates, use a tubular centrifuge to remove small impurities in the astragalus polysaccharide, and use a 0.2 micron ceramic membrane module to micro-filter to remove macromolecular substances. Perform circulating ultrafiltra...

Embodiment 3

[0034] A preparation method for preparing astragalus polysaccharide iron, comprising the following specific steps:

[0035] (1) Extraction and purification of astragalus polysaccharides: take the astragalus medicinal material and crush it into a coarse powder, then reflux extraction with distilled water with a weight ratio of 1:6 for 2 hours, a total of 3 times, and then add 55% ethanol to the reflux liquid extracted by reflux The solution was subjected to microwave treatment 3 times under the conditions of power of 600W and pressure of 0.2MPa, each time for 48s, and microwave treatment was stopped for 25s after each microwave treatment to obtain a microwave extract, which was passed through a 100-mesh copper sieve to remove coarse slag, collected Merge the filtrates, use a tubular centrifuge to remove small impurities in the astragalus polysaccharide, and use a 0.2 micron ceramic membrane module to micro-filter to remove macromolecular substances. Perform circulating ultrafil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com