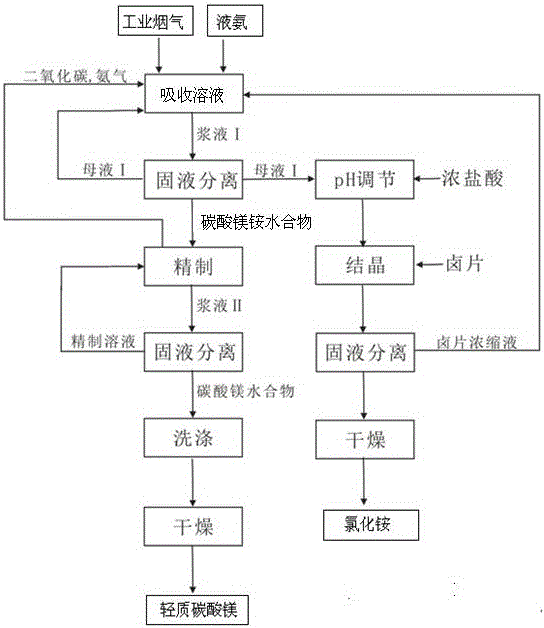

Method for combined production of lightweight magnesium carbonate and ammonium chloride based on carbon dioxide sequestration

A light magnesium carbonate and carbon dioxide technology, applied in the direction of ammonium chloride, magnesium carbonate, ammonium halide, etc., can solve the problems of high preparation temperature, equipment corrosion, high energy consumption, etc., and achieve low cost, energy saving, and no environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) 1500ml of ammonium chloride solution is prepared, and the concentration of ammonium chloride is 3mol / L. The waste material produced by drying potassium salt in salt lakes is the magnesium chloride solution of 6mol / L for raw material preparation concentration, and the two kinds of solutions are added to the crystallization reactor and mixed Uniformly used as an absorption solution, the volume ratio of ammonium chloride solution to magnesium chloride solution is 5:1, the pH of the solution is adjusted to 9.1 with liquid ammonia, and the flue gas discharged from a cement factory with a carbon dioxide volume fraction of 13% is passed into the absorption solution. The reaction temperature was 53.2°C for 6 hours to obtain slurry I;

[0043] (2) Filter the slurry I obtained in step 1 to obtain mother liquor I and ammonium magnesium carbonate hydrate, the purity of ammonium magnesium carbonate hydrate is 95%, the concentration of magnesium ions in mother liquor I is 0.004mol...

Embodiment 2

[0047] (1) 1500ml of ammonium chloride solution is prepared, and the concentration of ammonium chloride is 3mol / L. The waste material produced by drying potassium salt in salt lakes is the magnesium chloride solution of 6mol / L for raw material preparation concentration, and the two kinds of solutions are added to the crystallization reactor and mixed Uniformly used as the absorption solution, the volume ratio of the ammonium chloride solution and the magnesium chloride solution is 5:1, the pH of the solution is adjusted to 9.8 with liquid ammonia, and the flue gas discharged from the cement factory with a carbon dioxide volume fraction of 15% is passed into the absorption solution. Reaction at 47.6°C for 15 hours to obtain slurry I;

[0048] (2) The slurry I obtained in step 1 is filtered to obtain mother liquor I and ammonium magnesium carbonate hydrate, the purity of ammonium magnesium carbonate hydrate is 96%, the concentration of magnesium ions in mother liquor I is 0.002mo...

Embodiment 3

[0052] (1) 6000ml of ammonium chloride solution is prepared, and the concentration of ammonium chloride is 2mol / L. The waste material produced by drying potassium salts in salt lakes is a magnesium chloride solution of 6mol / L as a raw material, and the two solutions are added to the crystallization reactor and mixed Uniformly used as the absorption solution, the volume ratio of the ammonium chloride solution and the magnesium chloride solution is 3:1, the pH of the solution is adjusted to 9.3 with liquid ammonia, and the flue gas discharged from the cement factory with a carbon dioxide volume fraction of 15% is passed into the absorption solution, and in the reaction Reaction at 25°C for 20 hours to obtain slurry I;

[0053] (2) Filter the slurry I obtained in step 1 to obtain mother liquor I and ammonium magnesium carbonate hydrate, the purity of ammonium magnesium carbonate hydrate is 96.7%, the concentration of magnesium ions in mother liquor I is 0.008mol / L, and the concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com