High-strength multifunctional polyethylene communication pipe

A communication pipe and polyethylene technology, applied in the field of communication, can solve the problems of unbalanced rigidity and elastic modulus performance indicators, easy to produce brittleness, and affect service life, etc., and achieve good elastic modulus performance indicators, good corrosion resistance, and insulation performance good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

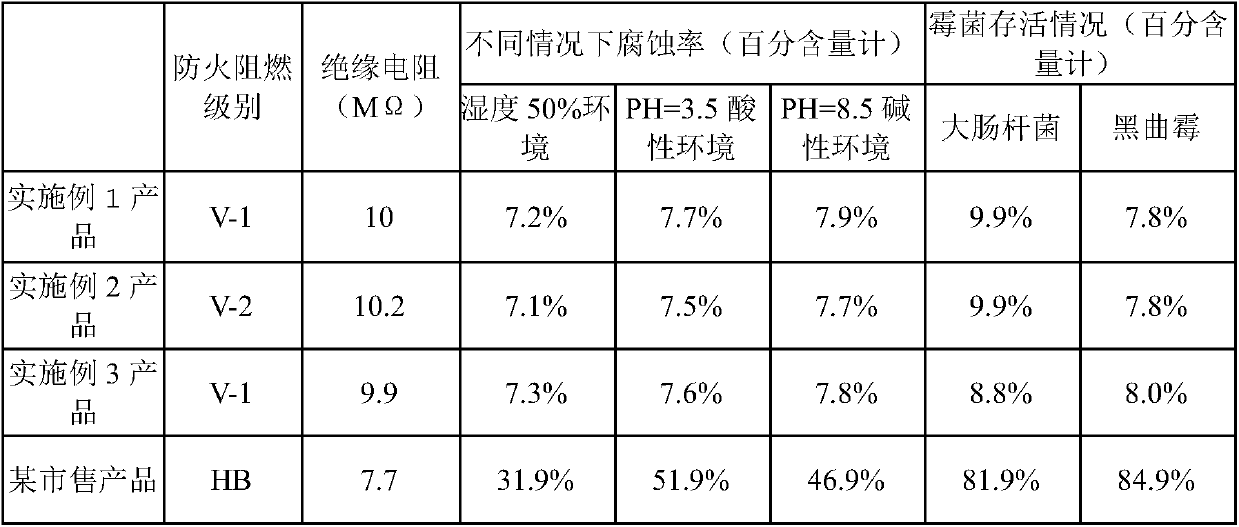

Embodiment 1

[0017] The high-strength multifunctional polyethylene communication pipe in this embodiment is composed of the following parts by mass: 28 parts of polyethylene, 26 parts of nitrocellulose plastic, 26 parts of bromobutyl rubber, 24 parts of caterpillar oil, 26 parts of allyl sulfide, 26 parts of linseed oil, 24 parts of ethyl silicone oil, 26 parts of nano silver, 26 parts of ethyl paraben sodium salt, 24 parts of penicillin, 24 parts of dodecyl ethoxy sulfobetaine Parts, 24 parts of sodium diacetate, 26 parts of wood fiber, 24 parts of zinc molybdate powder, 22 parts of nano aluminum powder, 26 parts of expanded perlite powder, 24 parts of metaborate, 22 parts of aluminum hydroxide powder, 24 parts of iron trichloride Parts, 22 parts of molybdenum trioxide powder, 22 parts of amidine urea phosphate, 24 parts of triisopropylphenyl phosphate, 24 parts of trichloroethyl phosphate, 24 parts of potassium titanate whisker reinforcement, 24 parts of pentaerythritol triacrylate Parts,...

Embodiment 2

[0024] The high-strength multifunctional polyethylene communication pipe in this embodiment is composed of the following parts by mass: 30 parts of polyethylene, 28 parts of nitrocellulose plastic, 28 parts of bromobutyl rubber, 26 parts of caterpillar oil, 28 parts of allyl sulfide, 28 parts of linseed oil, 26 parts of ethyl silicone oil, 28 parts of nano silver, 28 parts of ethyl paraben sodium salt, 26 parts of penicillin, 26 parts of dodecyl ethoxy sulfobetaine Parts, 26 parts of sodium diacetate, 28 parts of wood fiber, 26 parts of zinc molybdate powder, 24 parts of nano aluminum powder, 28 parts of expanded perlite powder, 26 parts of metaborate, 24 parts of aluminum hydroxide powder, 26 parts of iron trichloride Parts, 24 parts of molybdenum trioxide powder, 24 parts of amidine urea phosphate, 26 parts of triisopropylphenyl phosphate, 26 parts of trichloroethyl phosphate, 26 parts of potassium titanate whisker reinforcement, 26 parts of pentaerythritol triacrylate Parts,...

Embodiment 3

[0031] The high-strength multifunctional polyethylene communication pipe in this embodiment is composed of the following parts by mass: 32 parts of polyethylene, 30 parts of nitrocellulose plastic, 30 parts of bromobutyl rubber, 28 parts of caterpillar oil, 30 parts of allyl sulfide, 30 parts of linseed oil, 28 parts of ethyl silicone oil, 30 parts of nano silver, 30 parts of ethyl paraben sodium salt, 28 parts of penicillin, 28 parts of dodecyl ethoxy sulfobetaine Parts, 28 parts of sodium diacetate, 30 parts of wood fiber, 28 parts of zinc molybdate powder, 26 parts of nano aluminum powder, 30 parts of expanded perlite powder, 28 parts of metaborate, 26 parts of aluminum hydroxide powder, 28 parts of iron trichloride Parts, 26 parts of molybdenum trioxide powder, 26 parts of amidine urea phosphate, 28 parts of triisopropylphenyl phosphate, 28 parts of trichloroethyl phosphate, 28 parts of potassium titanate whisker reinforcement, 28 parts of pentaerythritol triacrylate Parts,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com