Antibacterial and anti-fingerprint composite film and preparation method thereof

An anti-fingerprint, composite film technology, applied in the direction of film/flake adhesive, coating, adhesive, etc., can solve the problems of difficult cleaning, fingerprint marks on the surface of the protective film, health hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The invention provides a method for preparing an antibacterial and anti-fingerprint composite film described in the above technical solution, comprising the following steps:

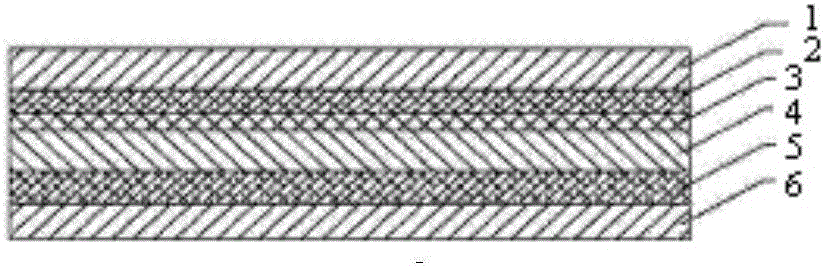

[0050] a) Coat one side of the functional substrate with an antibacterial and anti-fingerprint functional coating, followed by thermal curing and light curing to form an antibacterial and anti-fingerprint functional layer; apply an adhesive on the other side of the functional substrate, and thermally cure to form a functional adhesive layer, Then, the peeling substrate is covered on the functional adhesive layer to obtain a composite film intermediate, and the composite film intermediate includes an antibacterial and anti-fingerprint functional layer, a functional base layer, a functional adhesive layer and a peeling layer that are sequentially contacted;

[0051] b) one side of the protective film base material is coated with sizing material, and thermally cured to form a protective film adhesive ...

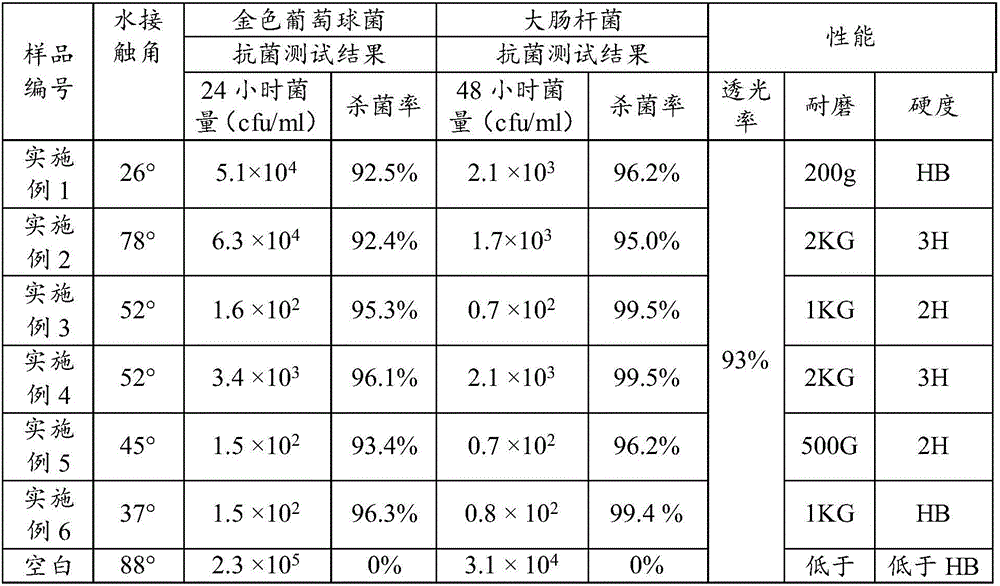

Embodiment 1

[0071] a) With 25 parts by weight of acrylic acid ester monomers, the acrylic acid ester monomers include methyl acrylate, ethyl acrylate, n-butyl acrylate and 2-ethyl acrylate in a mass ratio of 15:60:30:38 Base ethyl ester; The auxiliary film-forming agent of 7 weight parts, described auxiliary film-forming agent comprises the nitrocellulose film-forming agent and polyurethane film-forming agent that mass ratio is 3:7; The organic solvent of 30 weight parts, described organic solvent comprises Mass ratio is ethyl acetate and butanone of 3:14; The photoinitiator of 0.5 weight part, described photoinitiator comprises the azobisisobutyronitrile and fluorinated diphenyl titanocene that mass ratio is 3:5; The dimethyl diallyl ammonium chloride of the perfluoroalkoxy end group of 3 parts by weight, and the silver-containing nanoparticles of 3 parts by weight, the silver-containing nanoparticles comprising mass ratio of 4:5:7 Silver-loaded zeolite, sodium silver silicoborate and ti...

Embodiment 2

[0081] a), with 28 parts by weight of acrylic acid ester monomers, the acrylic acid ester monomers include methyl acrylate, hydroxyethyl methacrylate, n-butyl acrylate and acrylic acid in a mass ratio of 17:8:2:48 -2-Ethyl ethyl ester; 7 parts by weight of auxiliary film-forming agent, said auxiliary film-forming agent comprising nitrocellulose film-forming agent and polyurethane film-forming agent with a mass ratio of 4:7; 20 parts by weight of organic solvent, so Said organic solvent comprises ethyl acetate and methyl ethyl ketone that mass ratio is 6:11; The dimethyl diallyl chloride of the azobisisopropionitrile of 0.3 weight part, the perfluoroalkoxy terminal group of 0.5 weight part Ammonium chloride and 2 parts by weight of silver-containing nanoparticles, the silver-containing nanoparticles comprising a mass ratio of 2:5:7 silver-loaded zeolite, sodium silver silicoborate and titanium dioxide silicon dioxide silver copper mixed to obtain antibacterial anti-fingerprint f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com