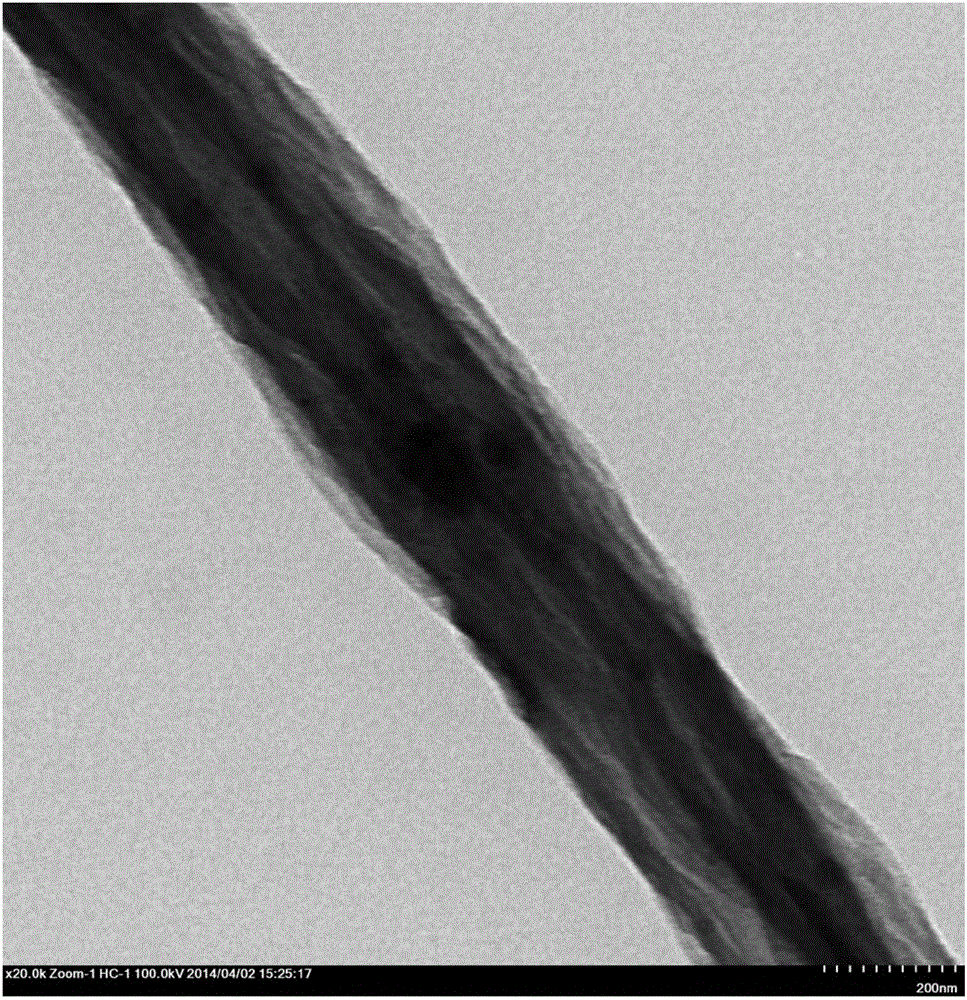

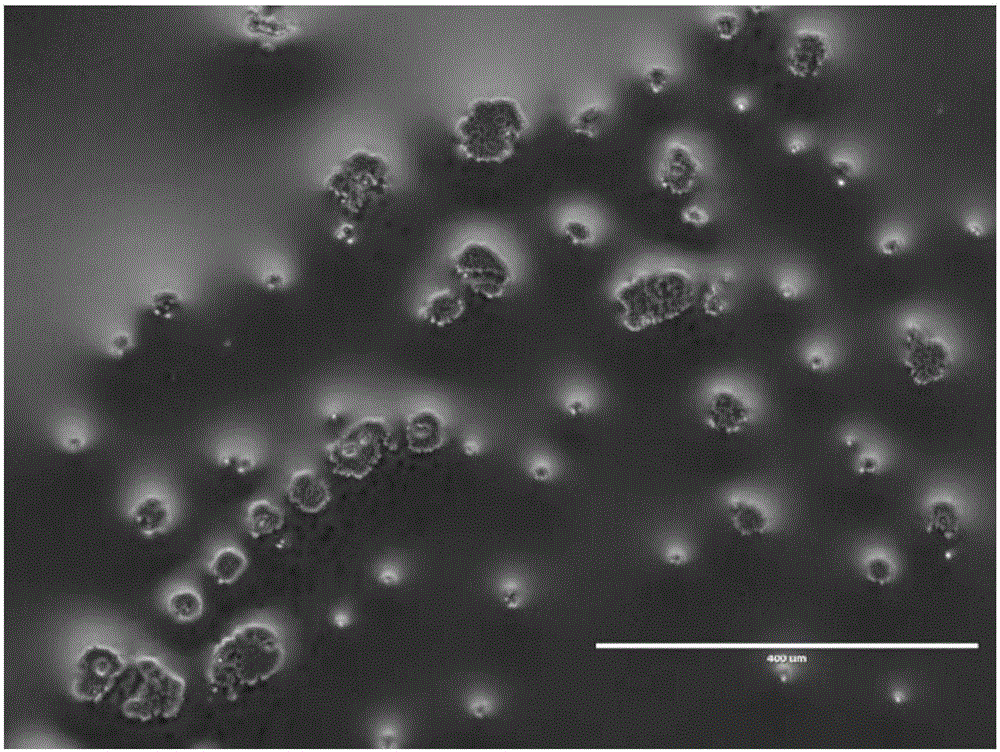

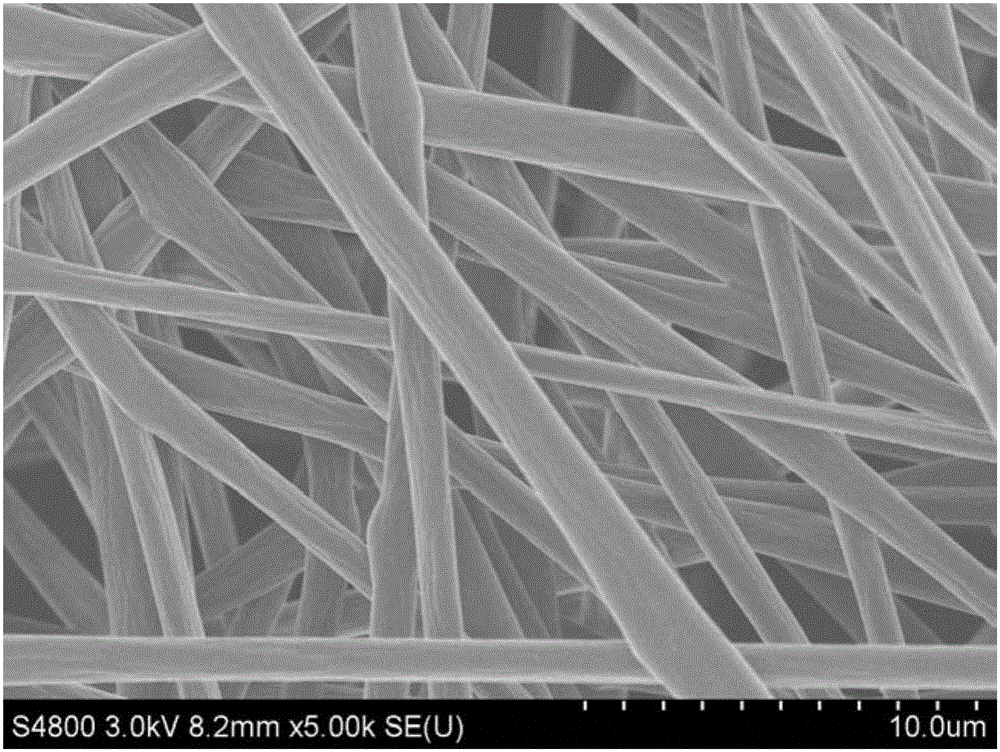

Multi-structure artificial blood vessel scaffold with inner layer capable of releasing NO gas and preparation method thereof

An artificial blood vessel and multi-structure technology, applied in the medical field, can solve the problems of low drug loading efficiency and achieve the effects of high loading efficiency, convenient operation, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] First, 0.1 g of hyaluronic acid (HA) was added to 9.9 g of distilled water, stirred to dissolve it completely, and an aqueous sol with a concentration of 1 wt % was prepared. Take 0.1g of 1wt% hydrosol, add 0.005g of nitrogen alcohol into it, and make it dissolve completely.

[0043] Next, first add 0.01 g of Span-80 (Span-80) to 4 g of dichloromethane (DCM), then slowly add the prepared hydrosol carrying NO substances into it dropwise, and use High-speed stirring on a magnetic stirrer for about 20 minutes, thereby preparing a relatively uniform water-in-oil (W / O) emulsion system containing drug-loaded hydrosol particles.

[0044] Then, 1.0 g of poly-L-lactic acid was added to the emulsion system, and after stirring and dissolving, 2 g of dimethylformamide (DMF) was added, and the stirring was continued to prepare a uniform and stable hydrosol electrospinning solution.

[0045] The electrospinning process is carried out at room temperature, and the experimental equipme...

Embodiment 2

[0047] Embodiment 2: The emulsifier is selected from one or more of Span 80, calcium hydroxide, zinc hydroxide, and magnesium stearate. One or more of chlorobenzene, dichlorobenzene, methylene chloride, dimethylformamide, and triethanolamine.

[0048] First, add 0.1 g of silk fibroin to 9.9 g of distilled water, stir to make it all dissolve, and prepare a hydrosol with a concentration of 1 wt%. Take 0.1g of 1wt% hydrosol, add 0.010g of nitrogen alcohol therein, and make it dissolve completely.

[0049] Next, first add 0.01 g of calcium hydroxide to 4 g of chlorobenzene, then slowly drop the prepared hydrosol carrying NO substances into it, and stir at high speed with a magnetic stirrer for about 20 minutes at room temperature , so as to prepare a relatively uniform water-in-oil (W / O) emulsion system containing drug-loaded hydrosol particles.

[0050] Then, 1.0 g of polyglycolic acid was added to the emulsion system, and after stirring and dissolving, 2 g of dichloromethane w...

Embodiment 3

[0054] First, add 0.1 g of collagen to 9.9 g of distilled water, stir to dissolve it completely, and prepare a hydrosol with a concentration of 1 wt%. Take 0.1g of 1wt% hydrosol, add 0.015g of nitrogen alcohol therein, and make it completely dissolve.

[0055] Next, first add 0.01 g of zinc hydroxide to 4 g of dichlorobenzene, then slowly drop the prepared hydrosol carrying and releasing NO substances into it, and stir at high speed with a magnetic stirrer at room temperature for about 20 Minutes, thereby preparing a relatively uniform water-in-oil (W / O) emulsion system containing drug-loaded hydrosol particles.

[0056] Then add 1.0 g of polylactic acid to the emulsion system, stir and dissolve completely, then add 2 g of triethanolamine, continue stirring, and finally prepare a uniform and stable hydrosol electrospinning solution.

[0057] The electrospinning process is carried out at room temperature, and the experimental equipment includes: a high-voltage DC power supply,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com