Production method and use of anion exchange online purification solid phase extraction monolithic column

A monolithic column and anion technology, which is applied in the field of analytical chemistry, can solve the problems of poor extraction capacity and pressure resistance, and achieve the effect of significant enrichment and purification, stable properties, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

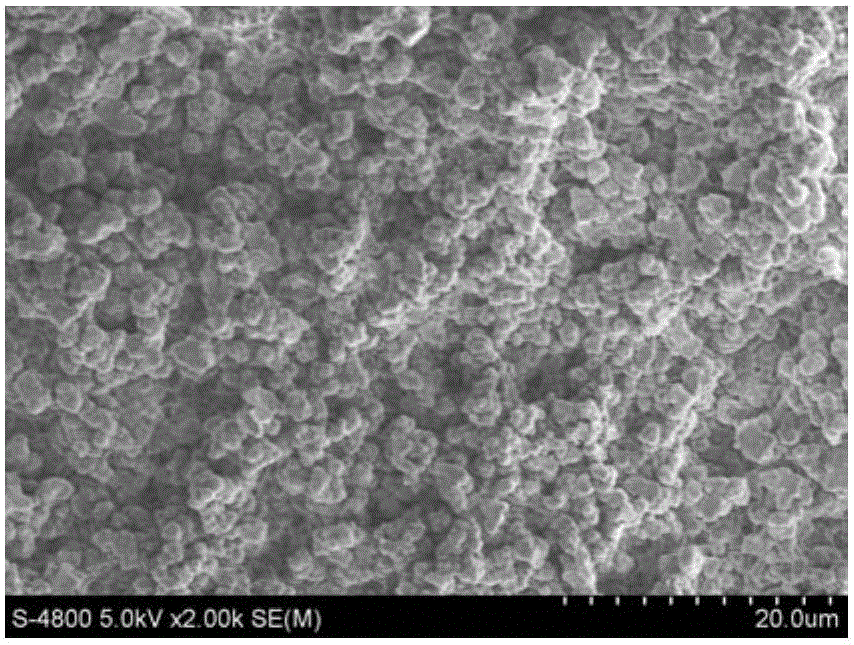

[0023] Embodiment 1: the preparation method of ploy (DMAEMA-co-EDMA) monolithic column

[0024] (1) Based on the total volume of reactants (1.25 mL), 3.7% monomer DMAEMA, crosslinking agent 20% EDMA, porogen 70%, initiator azobisisobutyronitrile 10 mg. Ultrasonic mixing and degassing at room temperature for 30 min.

[0025] (2) The solution was poured into a dry stainless steel empty column tube (10 mm×2.1 mm i.d.), both ends were sealed, and the temperature of the water bath was fixed at 55° C. and the reaction time was 30 h to prepare the monolithic column. And the monolithic column after the completion of the reaction is connected to the high-performance liquid chromatography high-pressure pump, and the monolithic column is washed with methanol to remove unreacted monomer and porogen to obtain a poly(DMAEMA-co-EDMA) monolithic column, which is ready for use .

Embodiment 2

[0026] Embodiment 2: the preparation method of ploy (DMAEMA-co-EDMA) monolithic column

[0027] (1) Based on the total volume of reactants (2.0 mL), 6.1% monomer DMAEMA, cross-linking agent EDMA 17%, porogen 80%, and initiator azobisisobutyronitrile 10 mg. Ultrasonic mixing and degassing at room temperature for 30 min.

[0028] (2) Afterwards, the solution was poured into a stainless steel column tube, both ends were sealed, and the temperature of the water bath was fixed at 65° C., and the reaction time was 20 h to prepare the monolithic column. And the monolithic column after the reaction is completed is connected to the high-performance liquid chromatography high-pressure pump, and the monolithic column is washed with methanol to remove unreacted monomers and porogens to obtain a poly(DMAEMA-co-EDMA) monolithic column, which is ready for use.

Embodiment 3

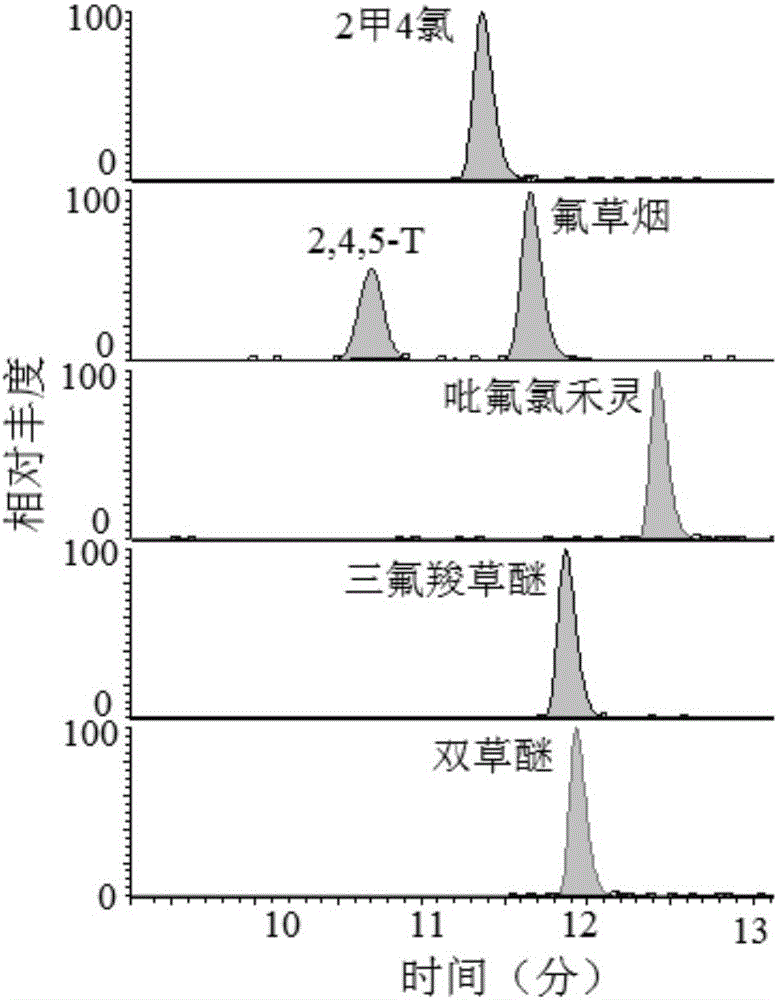

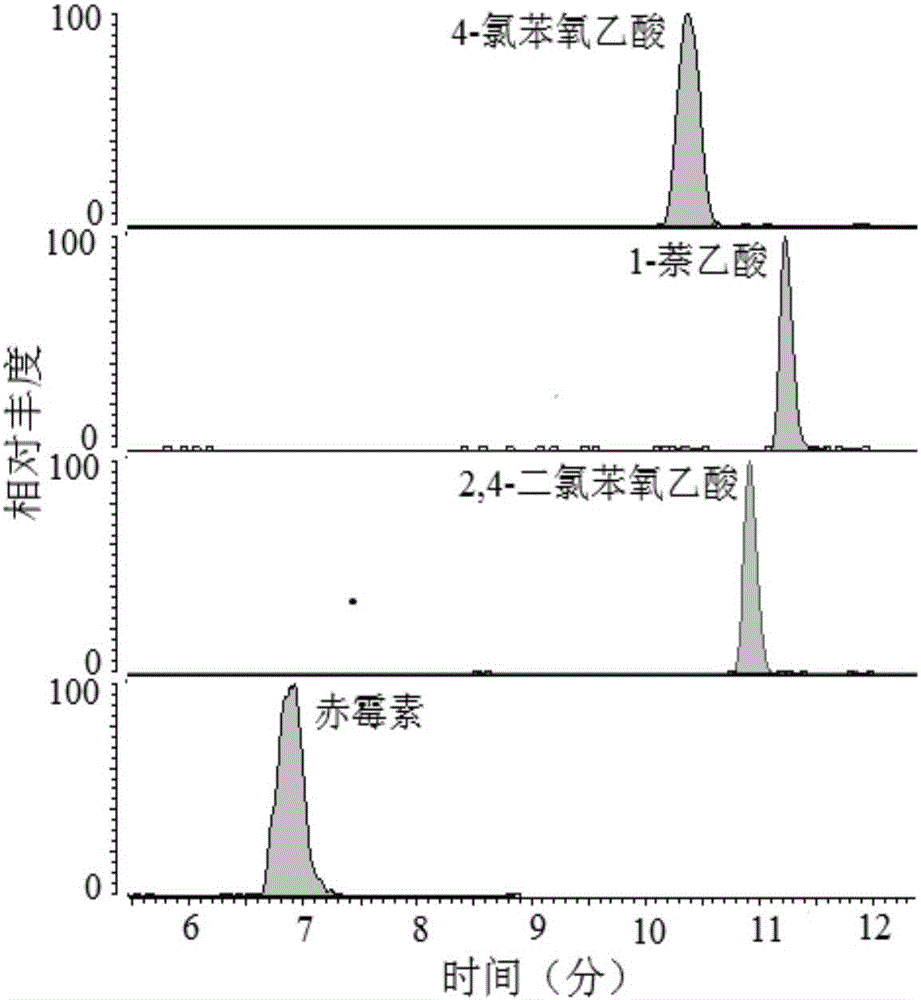

[0029] Example 3: Using the monolithic column prepared in Example 1 as the extraction medium, combined with liquid chromatography tandem mass spectrometry, the online purification and enrichment detection of five acidic pesticides in fruits

[0030] 1 sample processing

[0031] Accurately weigh about 10.0g of fresh pear and apple samples, put them in a 50mL centrifuge tube, add 10mL of acetonitrile, 5g of anhydrous sodium chloride, homogenize at 15000rpm for 1min, centrifuge at 5000rpm for 5min, take the supernatant in a 50mL centrifuge tube middle. Repeat the above extraction process twice, combine the supernatant, take 1mL of the supernatant, filter through a 0.22 μm microporous membrane, and wait for the test.

[0032] 2 test conditions

[0033] 2.1 Online purification conditions

[0034] The online SPE conditions are divided into 4 parts: loading, washing, elution and conditioning.

[0035] a) Loading: The mobile phase A of the loading pump is 5mmol / L ammonium acetate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com