Aluminum cathode anticorrosive paint for zinc electrodeposition and preparation technique thereof

An anti-corrosion coating, aluminum cathode technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of weak anti-penetration, short coating life, poor bonding force, etc., and achieve short manufacturing process and service life. Prolonged, anti-permeation and acid-resistant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

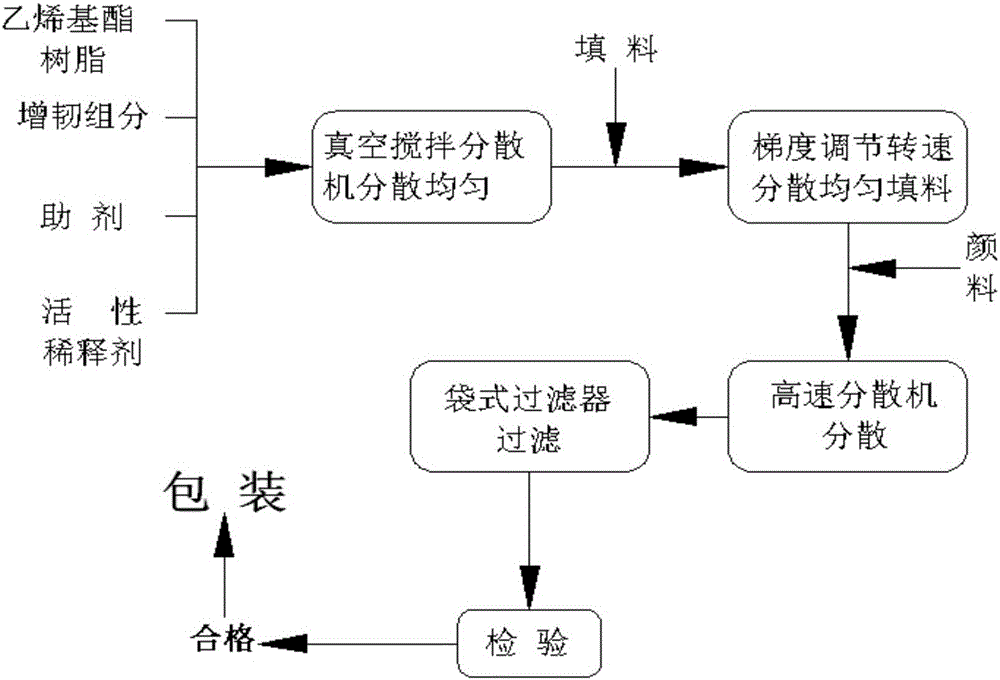

Image

Examples

Embodiment 1

[0018] The aluminum cathode anti-corrosion coating for zinc electrowinning in this embodiment includes A component, B component and C component, in parts by mass, and the composition of each component is as follows:

[0019] Component A: 100 parts of vinyl ester resin, 15 parts of reactive diluent, 10 parts of toughening component, 6 parts of auxiliary agent, 5 parts of pigment, 35 parts of filler;

[0020] Among them, the vinyl ester resin is made by mixing flexible vinyl ester resin, bisphenol F type epoxy vinyl ester resin and bisphenol A type epoxy vinyl ester resin in a mass ratio of 0.3:0.5:1; the active diluent is composed of Styrene and methyl methacrylate are mixed at a mass ratio of 1:1; the toughening component is composed of polyvinyl butyral (PVB), polytetrafluoroethylene micropowder (PTFE), CHX100 unsaturated terminal reactive liquid butyral Nitrile rubber is mixed at a mass ratio of 0.1:0.1:1; additives include 1 part of TEGO Foamex810 defoamer, 2 parts of TEGO ...

Embodiment 2

[0026] The aluminum cathode anti-corrosion coating for zinc electrowinning in this embodiment includes A component, B component and C component, in parts by mass, and the composition of each component is as follows:

[0027] Component A: 150 parts of vinyl ester resin, 25 parts of reactive diluent, 25 parts of toughening component, 12 parts of additives, 10 parts of pigment, 60 parts of filler;

[0028] Among them, the vinyl ester resin is made by mixing flexible vinyl ester resin, bisphenol F type epoxy vinyl ester resin and bisphenol A type epoxy vinyl ester resin in a mass ratio of 0.4:1:1; the active diluent is composed of Styrene and methyl methacrylate are mixed at a mass ratio of 1:2; the toughening component is composed of polyvinyl butyral (PVB), polytetrafluoroethylene micropowder (PTFE), CHX100 unsaturated terminal reactive liquid butyral Nitrile rubber is mixed at a mass ratio of 0.4:0.6:1; additives include 1.5 parts of TEGO Foamex810 defoamer, 5 parts of TEGO Dis...

Embodiment 3

[0034] The aluminum cathode anti-corrosion coating for zinc electrowinning in this embodiment includes A component, B component and C component, in parts by mass, and the composition of each component is as follows:

[0035] Component A: 120 parts of vinyl ester resin, 15 parts of reactive diluent, 20 parts of toughening component, 8 parts of additives, 8 parts of pigment, 40 parts of filler;

[0036] Among them, the vinyl ester resin is made by mixing flexible vinyl ester resin, bisphenol F type epoxy vinyl ester resin and bisphenol A type epoxy vinyl ester resin at a mass ratio of 0.1:0.3:1; Styrene is used; the toughening component is made by mixing polyvinyl butyral (PVB), polytetrafluoroethylene micropowder (PTFE), CHX100 unsaturated terminal reactive liquid nitrile rubber in a mass ratio of 0.3:0.4:1; The additives include 1 part of TEGO Foamex 810 defoamer, 4 parts of TEGO Dispers 655 wetting and dispersing agent, 0.5 part of TEGO Glide B 1484 leveling agent, 1 part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com